Choosing the Right Water Measuring Device A Complete Guide

You are participating in a critical field. The global market for water flow meters is valued at an impressive $14.89 billion. This highlights the importance of precise water measurement. Choosing the right water measuring device is essential for efficient monitoring and cost control. Poor measurement can lead to significant waste.

On average, water utilities lose around 16% of their total water supply. This loss comes from leaks and inaccurate meter readings.

This challenge drives innovation in water measurement technology. Smart water systems are expanding at a 7.9% annual rate, improving water flow measurement and flow control. This technology helps you manage your water resources effectively.

Defining Your Need: What Will You Be Measuring?

Before you select a water measuring device, you must first define your specific needs. The right meter for a home is very different from one used in a factory. Your application, water quality, and system pressure are key factors in your decision. This focus ensures accurate measurement and long-term performance.

Residential, Commercial, or Industrial Use

Your primary application is the first thing to consider. Residential, commercial, and industrial water flow meter uses have unique demands. A typical home needs a flow rate of 6 to 12 gallons per minute. Industrial sites, however, require much larger water flow meters to handle high-volume processes.

| Application | Typical Flow Demand | Common Meter Size |

|---|---|---|

| Residential | Low and consistent | Smaller (e.g., 3/4-inch) |

| Commercial | Moderate to high, variable | Medium (e.g., 1 to 2-inch) |

| Industrial | Very high and process-specific | Large (e.g., 2-inch and up) |

These differences also affect what data you need. Homeowners and utilities might track total water use for billing. A factory needs continuous flow data for process control.

Clean Water vs. Debris-Filled or Corrosive Water

The quality of the water you are measuring is critical. Clean, potable water works with most meter types. However, water with sand, debris, or corrosive elements requires a specialized solution.

For example, water from a well used for irrigation may contain sediment. A standard meter with moving parts could clog or wear out quickly.

For water with impurities, consider these options:

- Ultrasonic water flow meters have no moving parts, so debris can pass through without causing damage.

- Multi-jet meters are designed to better tolerate small impurities compared to single-jet systems.

Choosing a meter compatible with your water quality prevents inaccurate readings and frequent maintenance.

High-Pressure vs. Low-Pressure Systems

You must match your meter to your system's operating pressure. Every device has a maximum pressure rating. Exceeding this limit can damage the meter and lead to leaks or failure. A high-pressure industrial flow measurement requires a robust device built from strong materials. Low-pressure residential water systems have different requirements. Always check the manufacturer's specifications to ensure the meter can safely handle your water flow and pressure.

Understanding the Main Water Flow Meter Types

You must understand the main water meter types to make a good choice. The three most common water flow meter types are mechanical, electromagnetic, and ultrasonic. Each technology works differently and fits specific needs. Knowing these different water flow meter types helps you select the best tool for your job.

Mechanical Meters: The Traditional Choice

Mechanical water flow meters are the traditional option for measuring water. These devices use moving parts, like turbines or pistons, that spin as water passes through them. The speed of this rotation measures the volume of water. Positive displacement flow meters are a common type of mechanical meter. While effective, their moving components can wear down over time.

You should be aware that debris in the water can cause build-up or damage. This leads to fluctuating readings and a loss of accuracy. Regular inspection is important for this meter.

Electromagnetic Water Flow Meters (Mag Meters)

Electromagnetic water flow meters, or mag meters, offer a modern solution. These advanced water flow meters operate on Faraday's Law of Induction. They create a magnetic field, and as conductive water flows through it, the water generates a small voltage. The meter's sensors measure this voltage. A higher flow creates a higher voltage. This technology is excellent because it has no moving parts, reducing wear and maintenance. It is a very reliable choice for measuring conductive water.

Ultrasonic Water Flow Meters

Ultrasonic water meters also use modern technology without moving parts. These ultrasonic flow meters use sound waves to measure water flow. Two sensors send ultrasonic signals through the water, one with the flow and one against it. The device calculates the flow rate by measuring the time difference between these two signals. This type of velocity flow meter is highly accurate.

There are two main kinds of ultrasonic water meters:

- Transit-Time meters work best for clean water.

- Doppler meters are designed for water containing debris or bubbles.

This makes ultrasonic flow meters and their water flow sensors very versatile for many applications. These water meter types are a great option for long-term accuracy.

Other Specialized Water Flow Gauges

You may find that your project requires a unique solution. Beyond the common types, several specialized water flow gauges exist for specific jobs. These devices offer features tailored to unique conditions, such as agricultural irrigation or industrial processes. Choosing the right specialized meter ensures you get accurate data for your exact needs.

Propeller meters, for example, are a popular choice for measuring irrigation water. They work well in large pipes and can handle the high flow rates common in farming. Fire protection agencies also rely on durable water flow meters to test sprinkler systems and hydrants, ensuring they are ready for an emergency. The right meter provides critical flow information.

Your choice of meter should always match the water you are measuring. Some specialized water flow meters are designed for clean water, while others can handle water with chemicals or debris.

Here are a few other specialized water flow gauges you might encounter:

- Paddle Wheel Meters: These offer a simple and cost-effective way to measure water flow. A small wheel spins as water passes, and its speed determines the flow rate. You will often find this meter in large pipe applications where high precision is not the top priority.

- Oval Gear Meters: This type of meter uses two interlocking oval gears to measure a specific volume of water with each rotation. They are excellent for measuring low flow rates with high accuracy and can handle more viscous liquids than other water flow meters.

Ultimately, understanding these specialized options helps you find the perfect tool for any water measurement challenge.

A 4-Step Framework for Choosing Your Water Measuring Device

Selecting the right water measuring device does not have to be complicated. You can simplify the process with a clear, step-by-step approach. This framework helps you think through the most important factors. It guides you from your initial need to the final choice, ensuring you find a solution that is both effective and affordable.

Step 1: Match the Meter Type to Your Application

Your first step is to connect the different water meter types to your specific job. The best meter for farm irrigation is different from one used in a factory cooling tower. For example, a cooling tower system requires you to measure both the make-up water coming in and the blowdown water going out. This measurement helps you calculate efficiency and control chemical treatments. You must choose water flow meters designed for each specific water stream to get accurate data.

To make the best choice, you should evaluate several key factors. This checklist helps you think about your unique needs for various water flow meter uses.

- Pipe Size and Layout: Does your pipe have enough straight run for an inline meter? Or do you need a clamp-on meter that does not require cutting the pipe?

- Environmental Conditions: Will you install the meter outdoors? You may need a weatherproof model that can handle temperature changes and humidity.

- Water Quality: Is your water clean, or does it contain debris? This will help you decide between different water meter types, like a mechanical meter or an ultrasonic one.

Step 2: Balance Required Accuracy Against Budget

Next, you need to find the right balance between accuracy and cost. Highly accurate water flow meters often have a higher price tag. You must decide what level of precision your application truly needs. For billing purposes, you might need very high accuracy. For general monitoring of water flow, a less precise meter may be perfectly fine.

A good rule of thumb is to focus on the total cost of ownership. A cheaper meter that fails or gives bad readings can cost you more in the long run through waste and repairs.

The table below shows how different meter models can offer a range of features and accuracy levels. This helps you compare your options.

| Meter Series | Common Material | Accuracy | Key Feature |

|---|---|---|---|

| TM Series | PVC | +/- 3% | A cost-effective choice for general monitoring. |

| G2 Series | Stainless Steel | +/- 1.5% | Offers better accuracy for process control. |

| FPI Mag | N/A (Insertion) | +/- 0.5% | Provides high-precision measurement for critical tasks. |

By comparing these options, you can invest in a meter that provides the right level of measurement without overspending.

Step 3: Plan for Installation and Long-Term Maintenance

Your final considerations are installation and upkeep. The initial purchase price is only one part of the total cost. You must also account for the time, labor, and potential system shutdowns needed for installation. Some meters are much easier to install than others.

For example, installing a traditional full-bore meter on a large pipe can be complex and expensive. It often requires heavy equipment and shutting down your water flow. An insertion-style meter, however, can often be installed without stopping operations.

| Installation Factor | Full-Bore Meter | Insertion Meter |

|---|---|---|

| System Shutdown | Usually required | Not required (hot-tap install) |

| Installation Time | Can take many hours or days | Often installed in a few hours |

| Equipment Needed | May require cranes and welders | Basic tools are often sufficient |

| Overall Cost | High, especially for large pipes | Can save up to 45% on installation |

Maintenance is another important factor. A simple mechanical meter in a clean water system might not need any service for years. However, that same meter used with dirtier water may need monthly or quarterly cleaning to keep it working correctly. Always check the manufacturer's recommendations to create a maintenance plan that protects your investment.

Step 4: Determine Your Data and Monitoring Needs

Finally, you must think about the data you need from your water measuring device. A simple meter might only show the total volume used. A modern meter, however, can provide much more information. Your data needs will shape your choice between a basic gauge and a smart monitoring system. Ask yourself: Do you need to read the meter manually, or do you want data sent to a computer or phone?

Smart meters give you real-time data about your water usage. This information empowers you to make smart decisions. You can see exactly when you use the most water and find ways to conserve. For utilities, this data helps them spot leaks in the main system and manage the entire water supply more efficiently.

A study in the Canary Islands showed how powerful this information can be. When households received daily water consumption data on a web portal, they reduced their water use by about 2%. This shows that when you have access to data, you are more likely to change your habits.

If you are integrating the meter into a larger system, like a building automation system (BAS), you need to consider communication protocols. These protocols are like languages that allow different devices to talk to each other. Your meter must speak the same language as your control system.

- Modbus: This is a very common protocol in industrial automation. You can use it to connect your flow meter to electronic control equipment.

- BACnet: This protocol is designed for building automation. It allows your meter to integrate smoothly with your building's management system for smart water management.

Choosing a meter with the right output ensures you can track your water flow effectively. This final step connects your physical device to your data and control goals, completing your selection process.

Key Features of Modern Water Meters

Modern water flow meters offer much more than basic volume measurement. You will find that new water measurement technology includes smart features. These features give you greater control and insight into your water usage. Understanding these advancements helps you choose a meter that provides long-term value.

Remote Reading and Advanced Metering Infrastructure (AMI)

You no longer need to check your meter manually. Modern technology provides powerful remote monitoring capabilities. Advanced Metering Infrastructure (AMI) is a key part of this change. It connects your smart meter to your utility through a communication network. This system creates automated reading systems that collect data without a physical visit.

Advanced Metering Infrastructure (AMI) allows for two-way communication. Your meter sends data to the utility, and the utility can send commands back to the meter. This provides utilities with vast amounts of real-time data for better decision-making.

This technology sends frequent readings, sometimes every hour. This gives you a detailed look at your water consumption patterns. It helps you and your water provider manage resources more effectively.

Integrated Leak Detection Capabilities

The detailed data from smart water flow meters helps you find leaks quickly. These devices analyze your water flow patterns to spot problems. The meter looks for continuous flow, especially during times you typically use no water, like overnight. A constant flow often signals a leak somewhere in your system.

Smart sensors use specific methods to identify these issues:

- They analyze water flow data during low-demand periods.

- They compare your current usage to your normal patterns.

- They can trigger an alert if the flow suggests a leak.

This feature helps you save water and prevent expensive damage. You can fix small problems before they become big ones.

Material Composition and Device Durability

The materials used to build your meter are very important. The right material ensures your device lasts a long time and gives accurate measurement. You must choose a meter made from materials that can handle your specific water quality. For example, corrosive water requires a meter built from resistant polymers or stainless steel.

Modern designs also improve durability. For instance, ultrasonic water meters have no moving parts. This means there is nothing to wear out from friction or get clogged by debris. Their advanced water flow sensors provide reliable performance for many years. This reduces maintenance needs and ensures you get a great return on your investment.

Comparing Analog Gauges to Digital Monitoring Systems

You must decide between traditional analog gauges and modern digital systems. Your choice impacts how you collect data and manage your water. While simple gauges have their place, digital technology offers powerful advantages for efficiency and cost control.

When to Choose Simple Water Flow Gauges

Simple water flow gauges are a good choice for basic tasks. You might use them when you only need to know that water is moving. These gauges are often inexpensive and easy to install. If your application does not require high accuracy or detailed data, a basic mechanical meter can be a practical solution. Think of them for simple monitoring where you check the reading manually from time to time.

The Benefits of Upgrading to Digital Systems

You gain significant advantages when you upgrade to digital water flow meters. Digital instruments provide superior accuracy and reliability. They can store measured results for later analysis.

Digital water flow meters follow strict industry standards. This ensures their accuracy stays between 98.5% and 101.5% of actual usage. Their advanced water flow sensors and robust parts deliver precision for years.

Upgrading to digital systems also improves data collection.

- Automated data logging eliminates human errors from misreading or incorrect entry.

- Remote monitoring capabilities allow you to collect data without physically visiting the meter.

- This technology makes the entire process faster and more accurate.

Smart Water Monitoring for Maximum Efficiency

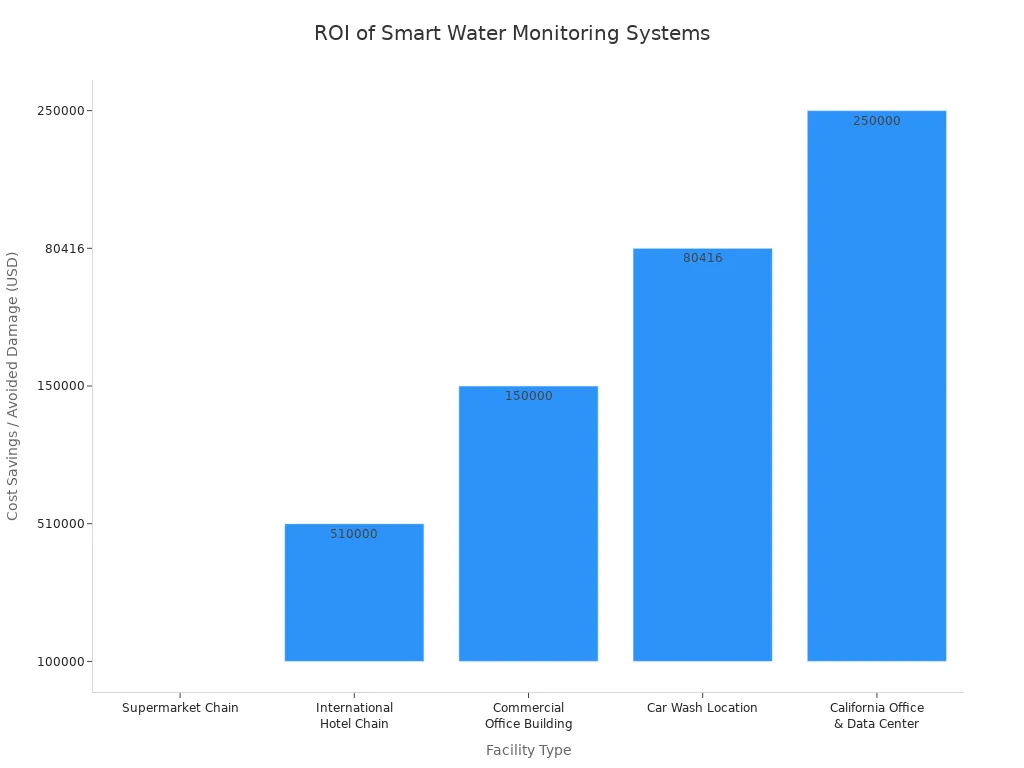

Smart water monitoring gives you maximum control over your water usage. These advanced systems use sensors to provide real-time data about your water flow. This information helps you spot leaks and reduce waste, leading to major cost savings. Many businesses see a quick return on their investment.

For example, a supermarket chain saved over $100,000 in annual water costs. An international hotel chain saved over $510,000. By using smart monitoring, you can prevent costly damage and optimize your water flow. This proactive approach protects your property and your budget.

Choosing the right water measuring device is a strategic decision. You must balance your application, water type, and budget for your water needs. Start by defining your specific requirements. Then, explore the main water flow meter types and other water meter types to find a match. Our 4-step framework guides your selection. This ensures you invest in a water measuring device that delivers accurate water flow measurement and performance for years of reliable water measurement and flow control.

FAQ

What is the best water meter for home use?

You have several good options for home use. A mechanical meter is a cost-effective choice for basic billing. If you want higher accuracy and leak detection features, you should consider upgrading to an ultrasonic or smart water meter for better long-term performance.

How often should you calibrate a water meter?

You should check the manufacturer's guidelines for calibration frequency. The need for calibration depends on the meter type and water quality.

For example, mechanical meters in water with debris may need more frequent checks than ultrasonic meters in clean water systems.

Can you install a water meter yourself?

You must check your local regulations first. Some jurisdictions require a licensed plumber to install any meter connected to the main water supply. While you might install a simple sub-meter yourself, professional installation is often necessary to ensure accuracy and compliance.

What makes a water meter "smart"?

A water meter becomes "smart" when it can communicate data electronically. These meters send your usage information directly to you or your utility. This technology allows for:

- Remote meter reading

- Real-time data monitoring

- Automatic leak detection alerts