Stop Guessing: A Comprehensive Guide to Troubleshooting Propane Tank Level Readings and Fixing Common Gauge Errors

There is nothing quite as unsettling on a freezing morning as walking out to your propane tank and seeing a gauge reading that just doesn't look right. Maybe it’s stuck stubbornly at 40% for weeks, or perhaps your brand-new digital monitor is flashing a “Calibration Error.” The immediate fear is twofold: cost (the emergency fill-up is always the most expensive) and safety (is the gauge hiding a real problem?).

In the demanding world of manufacturing and industrial operations, inaccurate propane tank level readings aren't just an inconvenience—they’re a critical threat to productivity and safety compliance. If you rely on LP gas for generators, specialized heating, or large-scale processes, you need certainty, not guesswork.

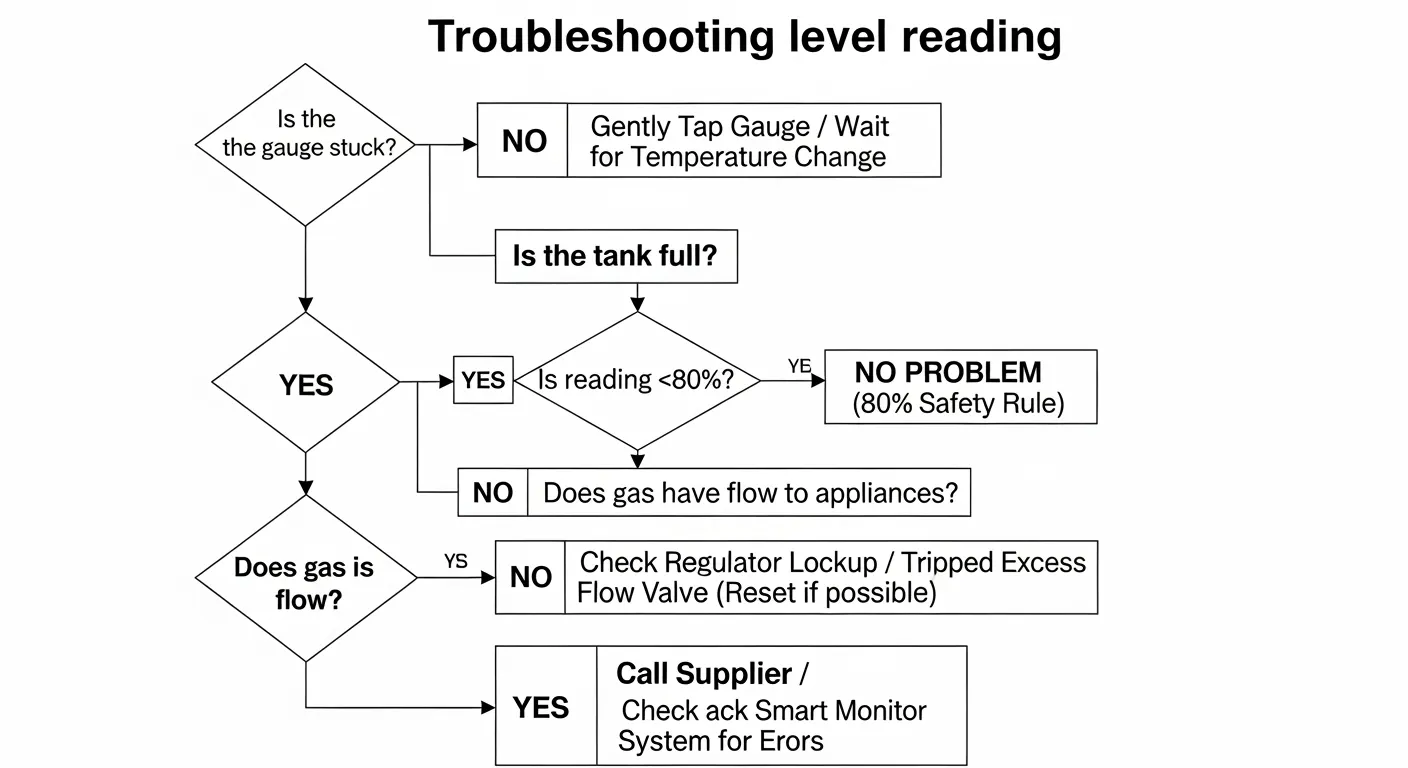

What I’ve found over 15+ years in the field is that most “faulty” gauge readings are not actually mechanical failures, but simple, physics-based phenomena or, increasingly, digital calibration oversights. This guide goes beyond the basic "tap the gauge" advice. We will dive deep into the technical causes behind the 7 most common LP gas gauge errors—from the venerable magnetic float system to the nuances of modern smart tank monitors—and provide you with the expert, actionable fixes you need. Stop the guesswork and regain control of your industrial fuel supply.

The Physics of the Problem: Why Propane Gauges Lie

Before we grab a wrench—or, more accurately, before we grab a phone to call the supplier—we have to understand the instrument we're dealing with. The standard gauge on a large propane tank is, fundamentally, an indicator, not a precision measurement device like a flow meter. Its primary role is to inform your refill schedule, not to provide laboratory-grade accuracy.

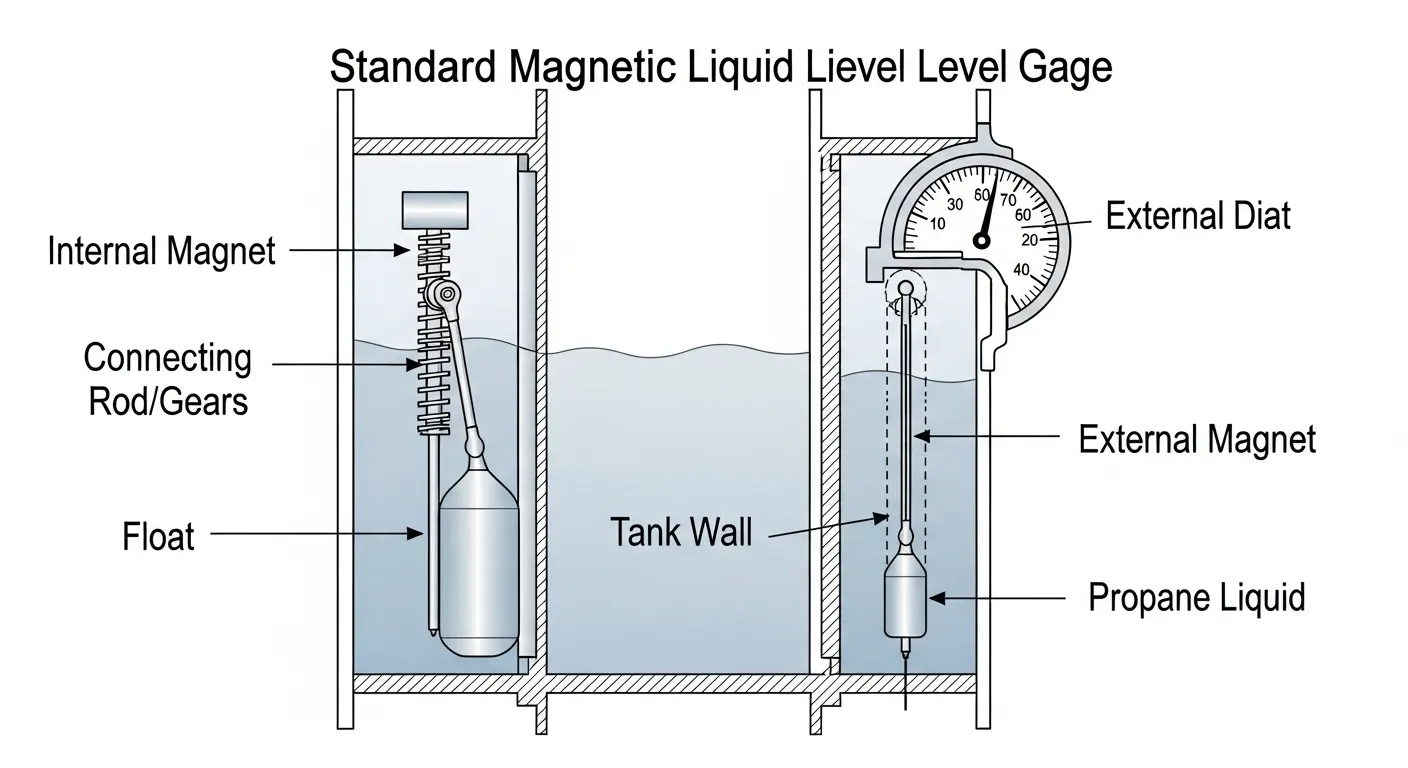

The standard gauge operates on a deceptively simple principle: the magnetic float mechanism.

The Magnetic Float Mechanism Explained

Inside the tank, floating on the liquid propane, is a physical float. This float is connected via a gear and lever system to a powerful magnet. As the liquid level rises or falls, the float moves the magnet. The gauge dial you see on the outside of the tank is simply another magnet mounted directly opposite the internal one. The magnetic attraction couples the two components, allowing the external needle to follow the internal float’s movement without ever breaching the tank’s pressure boundary.

This design is brilliant for safety, but it has inherent mechanical weaknesses: friction, the sheer weight of the assembly, and, most importantly, the fluid dynamics of the propane itself.

Temperature’s Direct Impact on Readings

If there is one thing you must appreciate about LP gas, it’s that its volume is extremely sensitive to temperature. This phenomenon is why your gauge is so often "lying" to you.

Propane, like any liquid, experiences thermal expansion and contraction. For every $10^{\circ}\text{F}$ rise in temperature, propane liquid expands by approximately $1.5\%$. This expansion is not gradual; it’s exponential.

Expertise Check: The 80% Safety Rule (NFPA 58)

The 80% fill limit is the biggest misunderstood "error" of all. Your supplier is never shorting you on gas. This limit is a non-negotiable safety standard rooted in the NFPA 58 (Liquefied Petroleum Gas Code). By only filling the tank to 80% capacity, we leave a mandatory $20\%$ vapor space to accommodate that extreme thermal expansion. Without that buffer, a hot day could dangerously increase the internal pressure, causing the pressure relief valve to vent propane—a hazardous situation no industrial setting can afford. A tank reading 80% on a standard gauge is full.

Conversely, when temperatures drop severely, the propane liquid becomes highly viscous and dense. This cold, sluggish liquid creates drag, impeding the float’s ability to rise or fall freely. This leads us directly to the most common issue we see in the winter.

Diagnosing the Top 5 Mechanical & Environmental Errors

When troubleshooting, always start with the most likely culprits. In my experience, 90% of industrial gauge complaints can be solved by addressing these physical and environmental factors.

1. The Infamous "Stuck Gauge"

This is typically a winter problem, but it can occur year-round. You used the tank all week, but the gauge hasn't moved from, say, 35%.

- Cause: The magnetic float is literally stuck. In cold weather, the highly viscous, cold propane liquid traps the float, or internal condensation and debris—sludge—has accumulated and created friction in the internal linkage. Another, less common cause is a loss of magnetic coupling due to violent movement (like an aggressive fill-up) or internal component friction.

- Fix: The Only Safe DIY Intervention. First, let’s rule out viscosity. If the tank is cold, give it time for temperature stabilization. The most you should ever do is use a gloved hand to gently tap the face of the gauge dial. Do NOT hit the tank body, the safety valve, or the gauge stem itself. A light tap on the external display housing is often enough to break the magnetic stiction and allow the needle to catch up. If the reading then suddenly drops (or rises), it confirms the stiction was the issue.

- Trustworthiness Insight: If the gauge is persistently stuck, it's time to flag the unit. Never attempt to remove the gauge cover or stem yourself. That requires depressurizing the tank—a job for a licensed LP gas technician.

2. Stuck at 80% (The Full Tank Misconception)

We covered this above, but it bears repeating because it's the number one source of call-outs for new operators.

- Cause: This is not an error; it's a safety protocol. Per NFPA 58, the 80% reading means the tank is at its legally and physically safe fill limit.

- Fix: No fix required. Educate your team. If the reading is 80%, the tank is as full as it is permitted to be. The moment the propane volume drops below the 80% mark, it will begin to show a reading drop.

3. The 20% Plateau (Low-End Sludge)

If your gauge seems to work fine from 80% down to 25%, but then suddenly drops to 0% or stays locked at 20% until you run out, you likely have low-end buildup.

- Cause: Over years of use, heavy-end oil residues and other contaminants in the propane (including the odorant, ethyl mercaptan) settle at the bottom of the tank. This sludge interferes with the float's lowest range of motion.

- Fix: Call the Professional. The only remedy for persistent low-end sludge is a professional tank pump-out and cleaning procedure, which should be scheduled during your planned maintenance downtime. If you see this issue, factor it into your next tank certification or inspection cycle.

4. Physical Damage or Misalignment

Sometimes the simplest answer is the right one.

- Cause: The external gauge head has been struck by equipment, rotated, or the internal magnetic coupling has been physically decoupled due to vibration or shock. The internal rod may also be bent.

- Fix: Perform a simple visual inspection. Is the gauge housing intact? Is the dial facing the correct orientation? If you see a broken lens or a heavily rotated gauge, the tank needs to be tagged for professional inspection immediately.

5. Temperature Compensation Issues (Rapid Swing)

While cold slows the gauge, a rapid rise in temperature can temporarily cause an artificially low reading followed by a sudden increase.

- Cause: When the sun hits a tank after a cold snap, the vapor pressure rises almost instantly, but the temperature of the liquid propane and the heavy float mechanism takes longer to warm up. This creates a temporary disparity between the physical level and the pressure dynamics.

- Fix: Wait. Propane is a stable system. Give the tank several hours of stable ambient temperature to fully equalize. A quick drop in level followed by a slow rise back up is often just this thermal compensation in action.

Smart Monitor Errors: Troubleshooting Digital Readings

As industrial operations increasingly adopt LP Gas Smart Tank Monitoring, we trade one set of mechanical problems for a whole new set of digital ones. The most common errors here revolve around calibration and connectivity.

6. Calibration Drift (The K-Factor Mismatch)

This is the biggest mistake I see with remote monitoring systems, and it has nothing to do with the gas.

- Expertise Check: Whether the monitor uses an ultrasonic sensor, a pressure sensor, or an R3D gauge reader, it must be programmed with the correct K-factor (or tank geometry data). This programming tells the sensor's software: "When the float is at this specific physical height, it corresponds to that specific gallon volume in a tank of this size."

- Cause: The monitor was installed but was programmed for the wrong tank size (e.g., a 1,000-gallon tank setting on a 500-gallon tank). Over time, small errors in the algorithm’s initial zero-point cause the reading to drift, especially when nearing empty or full.

- Fix: Log into the monitoring platform or app. Verify the tank size programmed in the device settings against the actual capacity stamped on your tank’s data plate. If there is a mismatch, update it and initiate a re-calibration cycle. If the supplier installed it, call them to confirm the K-factor is correct.

7. Connectivity Issues and Dead Batteries

Digital data is only as good as the signal that delivers it.

- Cause: The overwhelming #1 cause of a smart monitor flatlining or failing to update is a dead battery or loss of signal strength (Wi-Fi or Cellular). Since most industrial tanks are outdoors, they are highly susceptible to signal interference, thick metal structures blocking the RF, or remote locations.

- Fix:

- Check the Battery: Most sensors are rated for 3-5 years. Check the battery status in the app. If low, contact the supplier immediately for replacement.

- Verify Data Schedule: Trustworthiness Insight: Smart monitors are not always real-time. To conserve battery, they often update only once or twice a day. If your reading hasn't changed in a few hours, it may just be waiting for its next scheduled "check-in."

- Perform a Hard Reset: Consult the monitor's user guide. Most digital monitors have a sequence (e.g., hold the button for 10 seconds) that forces a full network check and a data transmission.

Related Content Alert: Gauge Technology Comparison

For a deeper dive into the technological differences, you can check out our comparison of gauge types, which includes the float vs. the ultrasonic sensor models (A link to related content is placed here: LP Gas Tank Level Gauges Compared).

When to Call the Pros: Safety, Leaks, and Liability

We’re engineers and operators—we like to fix things ourselves. But when dealing with propane, your ability to intervene ends at the gauge face and the smart monitor's app. When in doubt, safety always trumps DIY efficiency.

The Safety First Mandate

If you suspect a leak (the distinctive "rotten egg" smell from the ethyl mercaptan odorant), or if you hear a hissing noise:

- Do NOT go near the tank or gauge.

- Do NOT attempt to tighten, loosen, or remove any component that handles pressure (the gauge stem, safety relief valve, or regulator connections).

- Action: Immediately initiate your site's emergency protocol, evacuate the area, and call your propane supplier or the fire department from a safe distance.

The Critical Distinction: Low-Flow or Low-Level?

A common, high-value scenario often confuses operators: the gauge reading is fine (say, 45%), but the appliance has shut off or the flame is extremely weak. This is a classic low-flow issue, not a low-level issue.

- Low-Flow Cause: The excess flow valve has tripped, or the regulator has locked up.

- Excess Flow Valve: This is a safety feature designed to stop gas flow if it detects a sudden, massive loss of pressure (like a line break). This usually happens when the main tank valve is opened too quickly.

- Regulator Lock-Up: The regulator, which steps down the tank pressure to usable appliance pressure, can malfunction, often due to high demand, water ingress, or age.

- Actionable Fix (Regulator Reset):

- Turn off the main valve on the propane tank.

- Turn off all appliance controls.

- Wait 5 minutes (this allows the system pressure to stabilize).

- Slowly, very slowly, open the main tank valve all the way.

- Wait 1 minute, then try lighting the appliances. If gas flow is restored, you successfully reset the excess flow valve or the regulator lock-up. If the problem persists, the regulator itself is faulty and must be replaced by a certified technician.

Long-Term Solutions: Avoiding Future Errors

If you are consistently battling inaccurate readings, the ROI on upgrading is clear: avoiding costly emergency deliveries and minimizing production downtime.

| Solution | Target Error Fix | ROI Benefit |

| Upgrade to Smart Monitor | Calibration, stuck gauges, low visibility | Eliminate guesswork, optimize delivery, reduce administrative time. |

| Scheduled Tank Cleaning | 20% Plateau (sludge) | Restore full tank capacity visibility, increase safety margins. |

| Regulator Inspection | Low flow/system lock-up | Maintain stable pressure, prevent costly appliance shutdowns. |

Conclusion

The vast majority of issues concerning troubleshooting propane tank level readings boil down to respecting the laws of physics and the standards of safety. The tank gauge is a simple instrument, sensitive to temperature, sludge, and rough handling. The smart monitor, while offering incredible control, introduces the digital complexities of calibration and connectivity.

Here are the key takeaways for your industrial operation:

- The 80% mark is the maximum safe fill. Never assume a reading below that means your supplier is shorting you.

- Cold temperatures are the primary cause of a "stuck" mechanical gauge.

- Smart monitor accuracy depends entirely on correct K-factor programming.

- If you suspect a leak, evacuate immediately. The only safe intervention is checking connections or resetting the smart monitor.

By applying this expert diagnostic framework, you turn guesswork into an informed, predictive strategy, ensuring your industrial processes run smoothly, safely, and cost-effectively.

Ready to upgrade your visibility from annual readings to hourly updates? Explore our guide to the best smart tank monitoring solutions. Smart Propane LP Gas Tank Monitoring Guide

Frequently Asked Questions

A light tap on the protective lens or the metal bezel of the standard gauge housing is generally safe to release a potentially stuck float caused by magnetic stiction or cold, viscous liquid. However, you should never use a hammer, wrench, or excessive force on any part of the tank, the stem, or the valves. If a light tap doesn’t work, call a technician.

Standard mechanical float gauges are designed as indicators, not precision instruments. They typically have a tolerance of $\pm 5\%$ under ideal conditions. Their accuracy is significantly reduced during extreme temperature swings. For high-precision requirements (e.g., industrial consumption tracking), an ultrasonic or hydrostatic smart monitoring solution is necessary.

This is almost always due to a rapid drop in ambient temperature. As the air temperature falls, the liquid propane contracts rapidly, causing the float to sink, and thus the reading to drop. Once the temperature stabilizes, the reading should remain consistent based on your consumption. This is physics, not a sign of a leak.

The exact process varies by manufacturer, but generally, you should: 1) Check the monitor’s user guide for the specific reset sequence. 2) Press and hold the primary button on the sensor for the specified time (e.g., 10 seconds). 3) Wait 5–10 minutes for the sensor to force a connection to the network and upload a new reading to the cloud platform.

A frozen gauge usually means there is condensation or water ingress around the gauge mechanism or within the regulator due to high humidity and low temperatures. If there is visible ice or frost on the main tank body, it is usually a sign of a rapid gas withdrawal rate (high demand), causing the liquid to cool drastically (the Joule-Thomson effect). This is a sign you may need a larger tank or vaporizer setup for your industrial load.

The gauge itself is entirely passive and will not cause an appliance to stop working. However, the conditions that cause a gauge error (like a rapid drop in pressure, a stuck float, or a very low liquid level) can often coincide with a pressure issue that trips the safety regulator, which will stop gas flow to your appliances. Always check for a tripped excess flow valve before assuming the tank is simply empty.