Understanding Propane Fill Levels: Why 80% Full Is a Safety Mandate

You just paid for a propane delivery, walked out to check the tank, and the gauge reads 80%.

It's a natural first thought: "Did I get ripped off? Am I paying for 20% of nothing?"

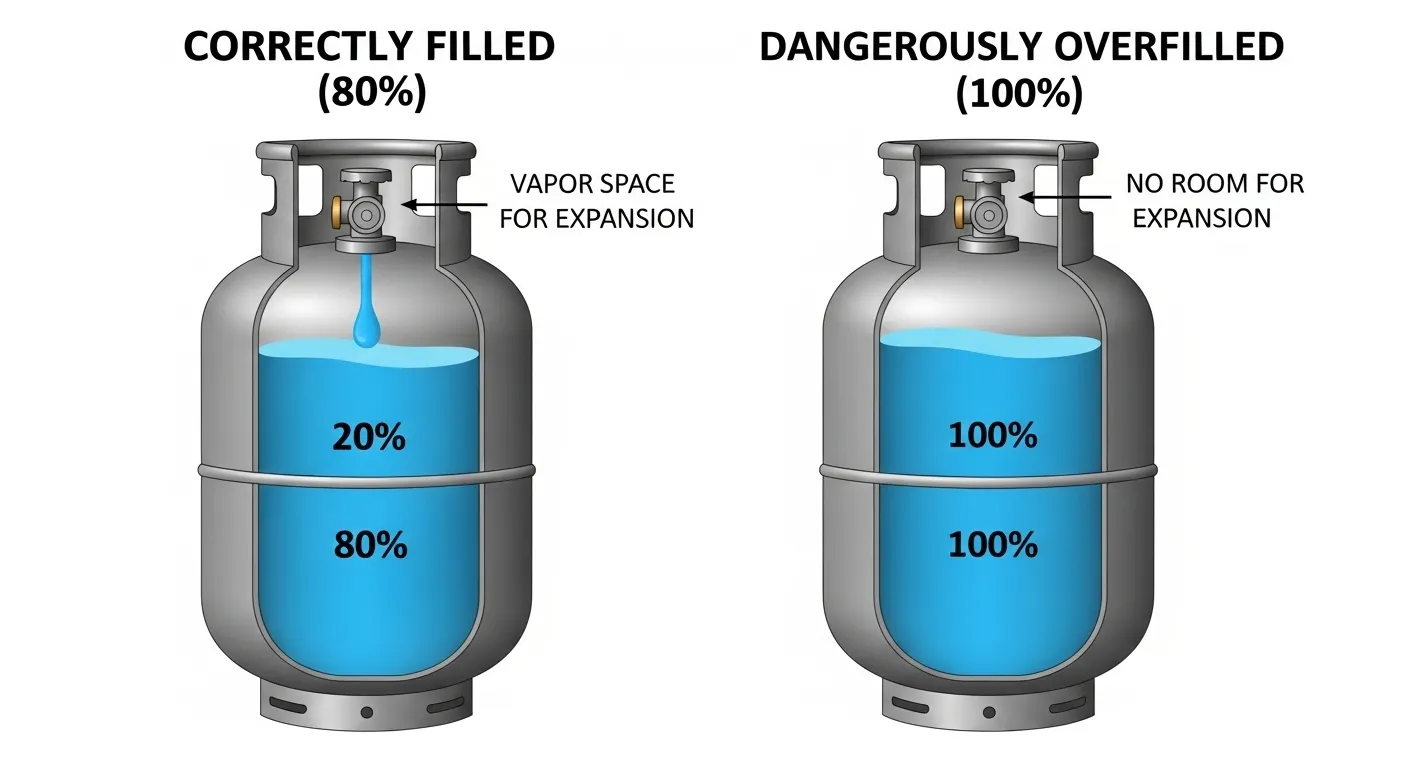

Let me put that concern to rest. Here's the direct answer: A propane tank is only filled to 80% capacity to leave a critical 20% "vapor space." This space is a non-negotiable safety buffer, required by law, to allow for thermal expansion.

In this guide, we're going to go way beyond that simple answer. We'll dive into the physics of propane, the very serious dangers of overfilling, and the specific safety systems designed to protect your home or facility.

In my 15+ years in the energy and industrial sector, I can tell you this isn't just a "best practice"—it's the single most important safety rule in gas handling.

The "80% Rule": Your Tank's Most Important Safety Feature

The 80% rule is the industry-wide, legally-mandated maximum fill level for all propane containers, from your 20lb grill tank to a 1,000-gallon industrial tank.

Let's be crystal clear about the money: you are not paying for the 'empty' 20% space. You pay per gallon dispensed. That 20% buffer is a safety feature you aren't charged for, like the airbags in your car. It's just there for safety.

This buffer is called vapor space. To understand why it's so critical, you have to understand the unique physics of propane.

The Physics of Propane

To really get this, you have to understand what propane is. It's stored as a liquid under pressure, but its natural boiling point is a frigid -44°F (-42°C).

What does that mean? It means on any day warmer than -44°F (which is, well, always), the liquid propane in your tank is actively trying to boil and turn into a gas. This boiling creates pressure, which is what sends the fuel to your furnace or appliances.

Here's the kicker, and the most critical fact many people miss: Liquid propane expands dramatically with heat.

For the same temperature increase, liquid propane's volume will grow about 17 times more than water. That 20% vapor space gives this expanding liquid room to "breathe." As the temperature rises, the liquid expands, the vapor compresses, and the pressure inside the tank stays at a safe, stable level.

Without that space, even a mild, sunny day can turn a tank into a high-pressure emergency.

What Happens If a Propane Tank Is Overfilled?

So what actually happens if a tank is filled to 95% or 100%? This is where theory meets dangerous reality.

When a tank is in a "liquid-full" state, even a minor temperature increase—say, the sun coming out from behind a cloud—causes the liquid to expand. With nowhere to go, the pressure inside the tank spikes. I'm not talking a small amount; I mean it spikes exponentially. This is called hydrostatic pressure.

Every tank has a pressure relief valve. It's the last line of defense. When that dangerous pressure is hit, the valve will open and vent propane to save the tank from rupturing.

But here's the problem: it won't be venting vapor. It will be venting highly flammable liquid propane, which will flash-vaporize into a heavy gas and pool near the ground, creating a massive fire hazard.

The Worst-Case Scenario: BLEVE

This is the term that separates the pros from the amateurs: BLEVE. It stands for Boiling Liquid Expanding Vapor Explosion.

A BLEVE is the catastrophic failure. It happens when an overfilled tank is also exposed to an external fire.

- The fire heats the tank.

- The internal pressure is already dangerously high from being overfilled.

- The flame weakens the tank's metal shell.

The tank ruptures, and the entire 500 gallons of liquid propane flash-boils instantly. The result is a massive, devastating fireball.

This is not a scare tactic. This is physics. This is why the 80% rule is non-negotiable. The entire safety protocol for the industry—from fill levels to valve design—is codified in NFPA 58: The Liquefied Petroleum Gas Code. It's all built to prevent a BLEVE.

The Safety Systems That Enforce the 80% Rule

How does a technician know when to stop? They don't just watch the gauge and guess. They use two specific tools, and the one they use depends on your tank.

1. The OPD (Overfill Prevention Device)

This is the safety float mechanism inside portable cylinders, like the 20lb tank for your grill. If you've tried to get an old tank filled in the last 20 years, you may have been turned away—it's because it didn't have a modern OPD valve.

Here’s how it works:

- As liquid propane enters, it lifts a float arm (just like the one in your toilet tank).

- When the liquid level reaches 80%, the float arm instantly snaps a valve shut, stopping the flow of liquid dead.

This is why you can't just "top off" a modern grill tank. The OPD valve physically prevents it. Anyone trying to bypass it is breaking the law and risking your safety.

2. The 80% Bleeder Valve (Fixed Liquid Level Gauge)

This is what professionals use on large, stationary ASME tanks (the big ones for your home or business). In my experience, this is the most reliable tool on the truck. If you've ever been home during a fill, you've probably heard a sharp 'hissing' sound. That's this valve.

It's a simple, brilliant device: a small tube inside the tank that is fixed to end at the 80% liquid level.

- When the technician fills, they open this "bleeder valve." At first, it spits out propane vapor, which is mostly invisible.

- They keep filling. The instant the liquid propane level hits that 80% mark, the valve starts to spit a dense, white stream of liquid.

That is the unmistakable, physical signal to the driver to shut down the fill immediately.

How to Read Your Gauge (And Why It Fluctuates)

This is the other big confusion I hear all the time. "My gauge read 82% yesterday, but it's 79% today. Do I have a leak?"

Probably not. You're just seeing the physics of propane in real-time.

How Your Float Gauge Works

First, you need to understand what that gauge is. On most home tanks, it's a float, just like the fuel gauge in your car. A small float bobs on the surface of the liquid propane and is connected via a magnet to the dial on the outside.

Here's the key thing most people don't realize: this gauge is an approximation. It is not a precision instrument. It’s designed to tell you if you're 'Full,' 'Half,' or 'Low,' not give you a perfect-to-the-decimal percentage. In my experience, a stuck or "gunked up" float is the #1 cause of a bad reading.

The Temperature Problem

This is where the physics we talked about comes back.

- Real-World Scenario: Let's say your supplier fills you to 80% on a cool 50°F morning. That afternoon, the sun beats down on the tank, and the temperature hits 90°F. The liquid propane expands. Your gauge might now read 83% or 84%. This is normal. It's the same amount of propane, just taking up more space.

- The Opposite: If you get a fill on a hot day (gauge reads 80%), and a cold front moves in, the liquid will contract. Your gauge might drop to 77%. This is also normal.

The bottom line: Don't panic over minor fluctuations. Trust that the supplier used the 80% bleeder valve, which is far more accurate than your tank's dashboard gauge.

Propane Fill Levels: Grill Tanks vs. Home Tanks

It's crucial to know that not all tanks are created equal. The two main categories are DOT cylinders (portable) and ASME tanks (stationary). They are regulated and filled differently.

Comparison Table

| Feature | 20lb Grill Tank (DOT Cylinder) | 500-Gal Home Tank (ASME Tank) |

| Regulation | U.S. Dept. of Transportation (DOT) | American Society of Mech. Engineers (ASME) |

| Primary Fill Safety | OPD (Overfill Prevention Device) | 80% Bleeder Valve (Fixed Liquid Level Gauge) |

| Filled By | Usually at a "swap station" or fill center | By a trained technician from a delivery truck |

| 80% Capacity | Approx. 4.7 gallons (or 20 lbs) | 400 gallons |

| Gauge Type | Often has no gauge (filled by weight) | Float gauge (reads percentage) |

Conclusion: Trust, Safety, and Science

Understanding propane fill levels isn't about billing; it's about understanding the power and physics of the fuel you rely on. That 'empty' 20% in your tank isn't waste—it's the most critical safety component you own.

Here are the key takeaways:

- The "80% Rule" is a mandatory safety law, not a sales tactic.

- The 20% vapor space is essential to allow for propane's high rate of thermal expansion.

- Overfilling can lead to valve rupture and, in a worst-case scenario, a BLEVE.

- Certified technicians use OPD valves or 80% bleeder valves for a safe, accurate fill.

- Your tank's gauge is an approximation; expect it to fluctuate with temperature.

Have questions about your last fill, or is your tank's gauge acting erratically? Contact our certified propane specialists today to schedule a safety inspection and ensure your system is running perfectly.

Frequently Asked Questions (FAQ)

A "20lb tank" refers to the weight of the propane it's designed to hold (which is ~80% of its total capacity). The empty tank itself (its 'tare weight') is usually 17-18 lbs, making a 'full' and safe tank weigh around 37-38 lbs total.

A 500-gallon tank has a total water capacity of 500 gallons. Its maximum propane capacity, at 80%, is 400 gallons. This allows for the 100-gallon (20%) vapor space for expansion.

Yes, it's not recommended. When a tank is 100% empty, it loses its positive pressure. This can allow moist air to get inside, leading to internal rust. Rust can clog filters and, more importantly, can mask the smell of propane, making a leak harder to detect. It also requires a professional leak test before refilling.

That's the common industry term for the 80% bleeder valve (or fixed liquid level gauge). It's the small valve a technician opens during filling. It 'spits' vapor until the liquid reaches the 80% level, at which point it spits liquid, signaling the fill is complete.

Why does my propane gauge read full all the time, then drop quickly?

This is a common observation. Your gauge measures the liquid level. But your appliances run on vapor. From 80% full down to about 20% full, the tank produces a very stable vapor pressure. Once the liquid level gets low (around 20%), the tank can't vaporize the fuel as fast, and the pressure (and the gauge) will seem to drop off a cliff. It's a sign you need to order a fill, fast.