Your 2025 Guide to Water Sensor Probe Materials

Choosing the right material for a water sensor probe is vital. It guarantees a high level of performance and a high level of reliability. For general freshwater applications, 316L Stainless Steel offers a balanced solution. Titanium provides the highest level of durability for saltwater or corrosive water. The growing demand for quality water monitoring drives the market for water quality sensors.

The global market for water quality sensors is projected to reach $5.094 billion in 2025, showing the need for better sensors.

The quality of these sensors directly impacts the level of accuracy and sensor longevity. The ideal material choice maintains a high level of quality for the sensor. It considers the specific water conditions to achieve a high level of performance and a high level of monitoring.

A Deep Dive into Common Water Sensor Probe Materials

Selecting the right material is the most important step in ensuring the accuracy and longevity of water quality sensors. Each material has unique properties. These properties make it suitable for specific environments. Understanding these differences helps operators maintain a high level of data quality and extend the life of their equipment. This deep dive explores the most common materials used for water quality sensors.

Stainless Steel (304 vs. 316L)

Stainless steel is a popular choice for its strength and affordability. However, not all stainless steel offers the same level of protection. The two most common grades are 304 and 316L. The key difference lies in their chemical makeup. 316L contains molybdenum, an element that significantly boosts its corrosion resistance.

| Grade | C (max) | Si (max) | Mn (max) | P (max) | S (max) | N (max) | Cr (%) | Ni (%) | Mo (%) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 17.5 - 19.5 | 8.0 - 10.5 | - |

| 316 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 16.5 - 18.5 | 10.0 - 13.0 | 2.0 - 2.5 |

The "L" in 316L indicates a low carbon level. This low carbon level reduces harmful carbide precipitation during welding. This process preserves the material's corrosion resistance near the weld zone. The addition of molybdenum gives 316L a superior level of defense against chlorides, which are common in saltwater and industrial wastewater.

Key Takeaway: While 304 stainless steel is adequate for some freshwater applications, it is vulnerable to pitting in chloride-rich water. The molybdenum in 316L creates a higher quality passive film. This film provides a much lower corrosion rate, making it a reliable choice for a wide range of water monitoring tasks.

Titanium

Titanium stands out for its exceptional strength-to-weight ratio and unmatched corrosion resistance. It is virtually immune to corrosion from saltwater, acids, and other harsh chemicals. This makes it the premier material for demanding marine and industrial applications. Titanium sensors maintain a high level of performance even in environments where other metals would quickly fail. There are different grades of titanium, with Grade 2 and Grade 5 being common for sensors.

| Property | Grade 2 Titanium | Grade 5 Titanium |

|---|---|---|

| Tensile Strength | ≥ 345 MPa | ≥ 895 MPa |

| Operational Temp. | Up to 200°C | Up to ~400°C |

Grade 2 offers excellent corrosion resistance and is easily formed. Grade 5 provides a much higher level of tensile strength. The choice between them depends on the physical stress the sensor will endure. Titanium's hard, smooth surface also helps reduce fouling. Fouling is the accumulation of unwanted material on the sensor surface. This quality helps maintain a high level of measurement accuracy over time.

Plastics (PVC, CPVC, PVDF)

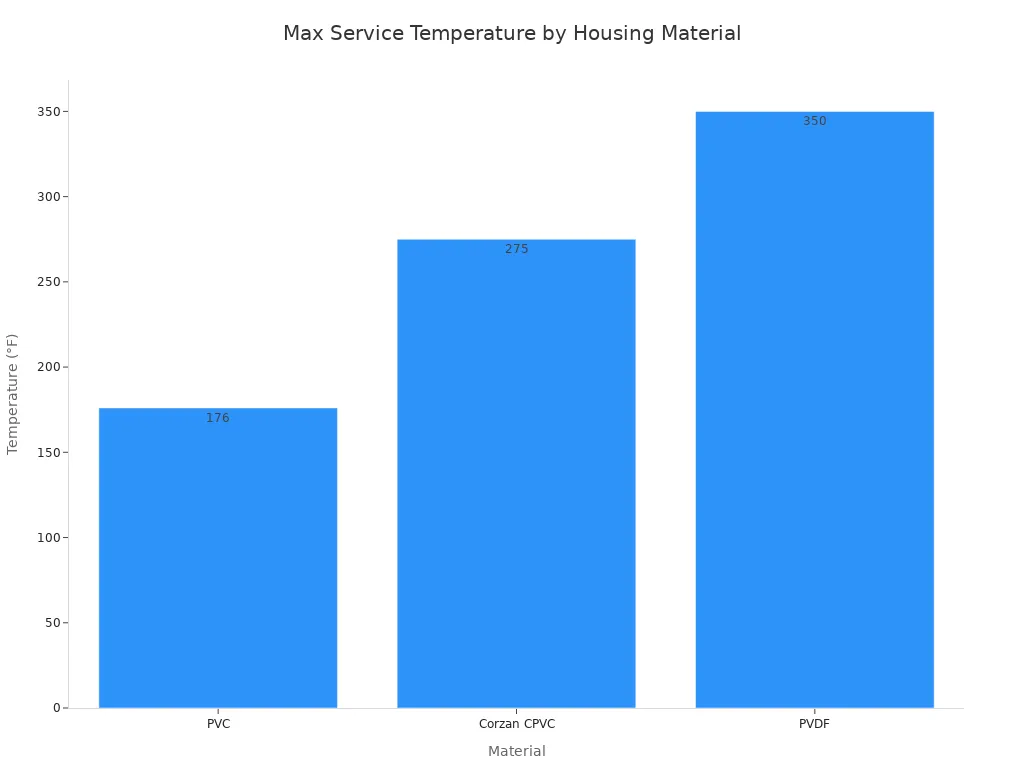

Plastics offer a lightweight and cost-effective alternative to metals for sensor housings. They are excellent for applications where metallic corrosion is a concern. Three common plastics are PVC, CPVC, and PVDF. Each offers a different level of chemical and temperature resistance.

- PVC (Polyvinyl Chloride): This is a widely used and inexpensive option. It works well in low-temperature, low-pressure water systems. It has good chemical resistance but a limited operational temperature.

- CPVC (Chlorinated Polyvinyl Chloride): CPVC can handle higher temperatures than standard PVC. This makes it suitable for hot water applications where PVC would deform.

- PVDF (Polyvinylidene Fluoride): PVDF provides the highest level of performance among these plastics. It has exceptional resistance to harsh chemicals, solvents, acids, and high temperatures. It also resists biofouling better than other plastics.

The operational limits of these plastics are a critical consideration. Temperature and pressure ratings determine their suitability for a specific system. PVDF consistently offers the highest level of temperature tolerance.

Pressure handling capability also decreases as water temperature increases. A water sensor probe made from these materials must operate within its specified limits to ensure structural integrity and a high level of quality for the data collected. The right plastic choice provides a durable and reliable housing for the sensitive electronics inside the sensor.

Specialty Alloys: Hastelloy C

Hastelloy C represents a family of high-performance nickel-based superalloys. These materials provide the highest level of protection in extremely corrosive environments where even 316L stainless steel and titanium cannot survive. The unique composition of nickel, chromium, and molybdenum gives Hastelloy an exceptional level of defense against a wide range of aggressive chemicals. This makes it a top-tier choice for specialized industrial sensors.

This alloy's primary advantage is its resistance to both oxidizing and non-oxidizing acids. This dual capability is rare among metals. It maintains a high level of structural integrity when exposed to substances that would quickly destroy lesser materials. Hastelloy C offers superior quality and performance against chemicals like:

- Concentrated hydrochloric acid

- Sulfuric acid

- Wet chlorine gas

- Phosphoric acid

- Strong oxidizers and reducing agents

Industries with severe process conditions rely on the robust quality of Hastelloy. Oil and gas operations use it for sensors in sour gas applications, which have a high H2S content. Its excellent resistance to crevice corrosion also makes it ideal for certain seawater applications. Additionally, advanced water and wastewater treatment facilities use this material for sensors to guarantee a high level of operational reliability. A water sensor probe made from Hastelloy ensures a high level of data quality in the harshest conditions. The durability of the sensor provides long-term value.

Key Takeaway: Hastelloy C is the ultimate material choice when sensor failure is not an option. Its unmatched chemical resistance ensures the highest level of measurement accuracy and longevity, protecting your investment and data integrity in the most demanding applications.

Matching Material to Water Type for Maximum Durability

Selecting the right material is crucial for the long-term performance of water quality sensors. The chemistry of the water directly impacts a sensor's lifespan and the quality of its data. Matching the probe material to the specific water type ensures reliability and prevents premature failure. This section breaks down the best material choices for common water environments.

Freshwater (Rivers, Lakes, Groundwater)

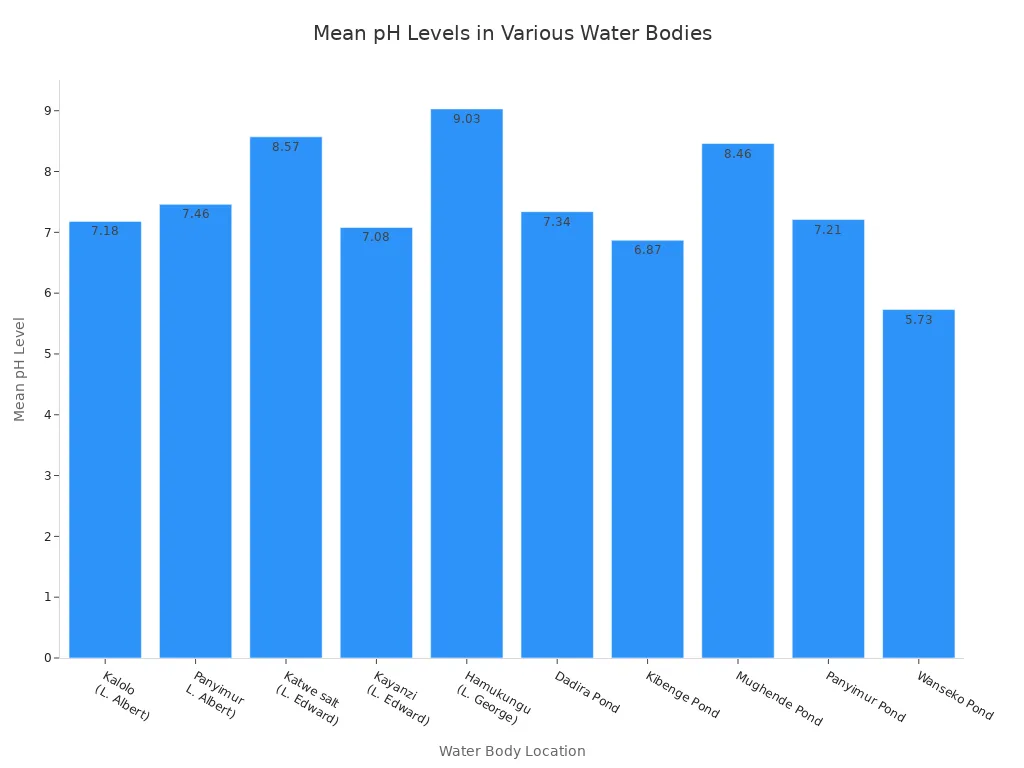

Freshwater sources like rivers, lakes, and groundwater typically have a neutral pH. Most freshwater bodies fall within a pH range of 6.5 to 8.5. However, local geology and organic matter can cause significant variations. Some ponds may be more acidic, while certain lakes can be more alkaline.

These environments generally contain low levels of corrosive chlorides. The main challenge in freshwater is often biofouling, where algae and other organisms grow on the sensor surface. This growth can interfere with measurements and reduce accuracy.

Material Recommendation: For most freshwater applications, 316L Stainless Steel offers the best balance of cost and performance. Its composition provides good resistance to general corrosion and is strong enough for long-term deployment. In less demanding systems, PVC can be a cost-effective option for the sensor housing.

Saltwater and Brackish Water

Saltwater and brackish water present a much harsher environment for water quality sensors. The defining characteristic is high salinity, which means a high concentration of dissolved salts, especially chlorides. Seawater has a very high chloride level, making it extremely corrosive to many metals. Brackish water, found in estuaries where freshwater mixes with seawater, has a lower but still significant chloride level.

| Water Type | Chloride Concentration (mg/L) | Salinity (mg/L) |

|---|---|---|

| Seawater | 19,400 | 35,000 |

| Brackish Water | 500-5,000 | 1,000-10,000 |

The high chloride content will attack and pit even 316L stainless steel over time. This corrosion compromises the sensor and leads to inaccurate data and eventual failure. Fouling is also a major issue in these nutrient-rich environments.

Material Recommendation: Titanium is the premier choice for any saltwater or brackish water monitoring. It is virtually immune to chloride corrosion, ensuring maximum durability and a high level of quality for liquid level monitoring. Its hard, smooth surface also helps reduce the rate of fouling, maintaining a high level of measurement accuracy over a longer period.

Wastewater (Industrial and Municipal)

Wastewater is a complex and often aggressive medium for any sensor. Its composition varies greatly between municipal and industrial sources. Municipal wastewater contains organic waste and cleaning chemicals. Industrial wastewater can contain a wide array of harsh chemicals, acids, and solvents. The pH level can fluctuate dramatically, often falling into acidic ranges below 6.0.

Common corrosive agents in wastewater include:

- Hydrogen Sulfide (H₂S): Creates acidic conditions.

- Chloride Ions: Cause pitting corrosion in metals.

- Aggressive Chemicals: Found in industrial discharge.

These substances demand robust materials to ensure the quality of the sensors. A standard material may degrade quickly, leading to costly replacements and data gaps. Choosing the right material is essential for reliable monitoring and process control.

Material Recommendation: For general municipal wastewater, 316L Stainless Steel may be adequate if the chemical composition is not overly aggressive. For industrial wastewater or any application with unknown or harsh chemicals, a higher level of protection is necessary. PVDF offers excellent chemical resistance for many applications. For the most extreme conditions involving strong acids, abrasive slurries, or high temperatures, Hastelloy C provides the ultimate level of protection. It ensures the highest quality of data and long-term performance, making accurate level monitoring possible in the toughest environments.

High-Purity and Laboratory Water

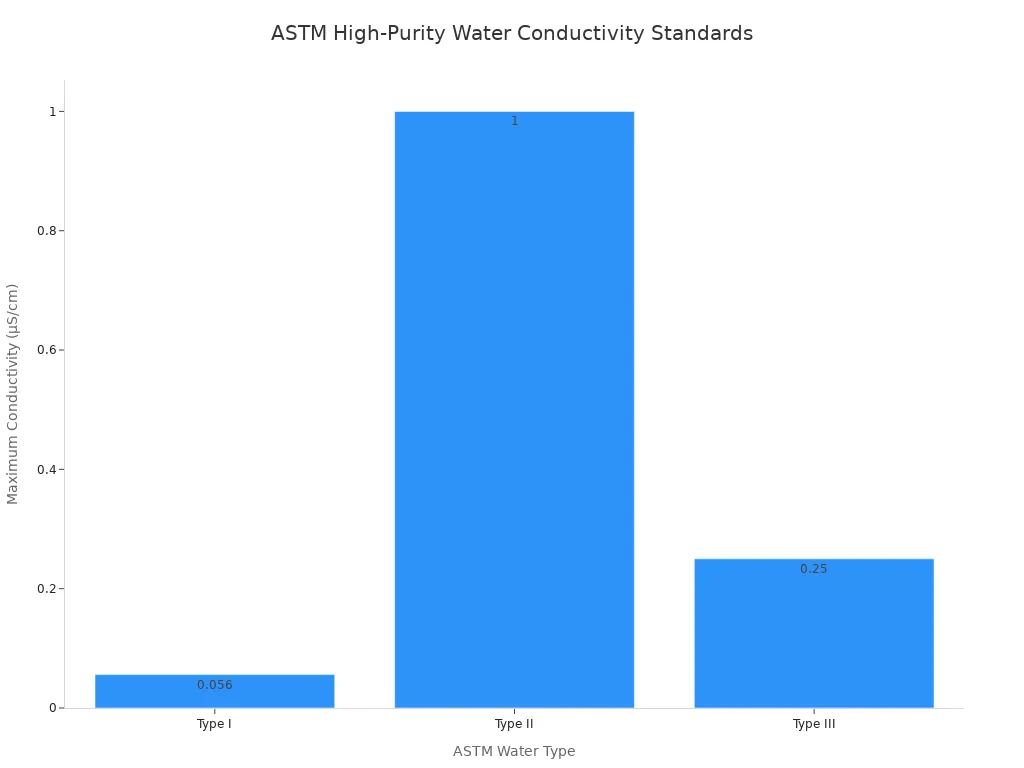

High-purity and laboratory water presents a unique challenge for monitoring equipment. This type of water is intentionally stripped of ions and minerals. Industries like pharmaceuticals, electronics manufacturing, and research laboratories rely on it. The absence of impurities makes this water highly aggressive. It actively seeks to pull ions from any material it contacts, a process known as leaching. This leaching can contaminate the pure water and degrade the sensor over time. Maintaining the highest level of purity is the primary goal.

The main risk in these applications is material leaching, not corrosion in the traditional sense. When a sensor leaches material, it introduces contaminants into the water. This compromises the quality of the water and the experiment or process. It also damages the water quality sensors, leading to inaccurate readings and eventual failure. The American Society for Testing and Materials (ASTM) defines standards for different types of pure water based on their conductivity. A lower conductivity value indicates a higher level of purity.

| ASTM Type | Conductivity (µS/cm) |

|---|---|

| Type I | < 0.056 |

| Type II | < 1 |

| Type III | < 0.25 |

Type I water has the lowest level of conductivity, making it the purest and most aggressive. The material for water quality sensors must not interfere with this delicate chemical balance. It must provide the highest level of inertness.

Using metallic sensors, including stainless steel, is not advisable. The deionized water will leach metal ions from the surface, altering the water's composition. This directly impacts the quality of the data and the process itself. The sensors must achieve a high level of performance without becoming a source of contamination.

Material Recommendation: Inert plastics are the best choice for high-purity water applications. PVDF is an excellent material because it is highly resistant to leaching and maintains a high level of structural integrity. It ensures the sensor does not add impurities to the water. For the most demanding applications requiring the highest level of purity, other fluoropolymers like PFA (Perfluoroalkoxy) are also used. These materials guarantee the quality of the measurements and protect the purity of the water.

Proper Maintenance for Your Water Level Sensors

Proper maintenance ensures the long-term accuracy and reliability of water level sensors. A consistent maintenance schedule prevents fouling, protects material integrity, and guarantees high-quality data. Following best practices for cleaning and calibration extends the life of all types of sensors, including float level sensors, and maintains their optimal performance.

General Maintenance Protocols

Regular maintenance is the foundation of dependable sensor operation. It involves both physical cleaning and electronic calibration. Preventing fouling is a primary goal, as biofouling can obstruct the sensor and lead to incorrect readings. Operators should establish a routine for cleaning and calibration.

A standard calibration process ensures the sensor provides accurate level measurements.

- Prepare the Sensor: First, ensure the sensor is clean and all connections are secure.

- Find the Zero Point: Position the sensor at the lowest water level and adjust its output to read zero.

- Find the Full Scale Point: Move the sensor to the maximum water level and set its output to the maximum distance.

- Calibrate the Sensor: Use calibration software to adjust the sensor based on the zero and full-scale points.

- Test the Sensor: Finally, verify accuracy by comparing sensor readings at different water levels with actual measurements.

This cleaning and calibration routine provides essential data verification for reliable monitoring.

Stainless Steel Probe Maintenance

Stainless steel sensors require specific maintenance to preserve their corrosion resistance. While durable, they can develop rust or scale in certain conditions. Gentle cleaning methods are best for removing light fouling.

For light rust, a paste of baking soda and water is effective. Apply the paste, let it sit, and scrub it off. For more significant rust, phosphoric acid can dissolve iron oxide without harming the steel.

After cleaning, a process called passivation restores the protective layer on 316L stainless steel. This treatment enhances corrosion resistance and extends the life of water level sensors. Proper maintenance of the material's surface is key to its quality and performance.

Titanium Probe Maintenance

Titanium sensors are known for their exceptional durability, but they still need correct maintenance. The material's protective oxide layer is key to its quality. Harsh chemicals can damage this layer. Operators should avoid traditional alkaline and acidic detergents for cleaning. These cleaners can leave a white haze that is difficult to remove.

The following should be avoided during maintenance of titanium float level sensors:

- Chlorinated solvents

- Harsh or abrasive chemicals

- Aggressive off-the-shelf detergents

Using gentle cleaning agents and soft cloths for cleaning and calibration helps protect the sensor. This careful approach prevents damage, reduces biofouling, and ensures the water level sensors deliver high-quality level data for years. The goal is to maintain the integrity of the sensor for consistent level monitoring. This proper maintenance of float level sensors ensures a high level of quality.

Plastic Probe Maintenance

Proper maintenance for plastic sensors, such as those made from PVC or PVDF, focuses on gentle handling and correct cleaning methods. While these materials resist chemical corrosion, they are more susceptible to physical damage and degradation from improper cleaning agents. Regular maintenance is crucial for preserving the structural integrity of these sensors and ensuring a high quality of level measurement. The calibration process is essential for confirming the sensor provides an accurate level.

The cleaning process for plastic float level sensors requires special care. Operators should use mild, non-abrasive detergents and soft cloths. Harsh chemicals, especially alcohol-based cleaners, can make the plastic brittle and cause it to crack over time. This damage compromises the sensor housing and can lead to failure. A consistent cleaning and calibration routine protects the quality of the equipment. The calibration procedure verifies the level readings. A final calibration check confirms the level accuracy.

A key part of maintenance is a thorough visual inspection. This helps identify signs of wear before they cause a complete failure of the water level sensors. Operators should look for the following issues:

- Cracked Housing: Small cracks or chips from impacts can worsen over time, allowing moisture to damage internal electronics.

- Cable Damage: Cuts or frays in the cable sheath expose wires and create a safety hazard.

- Seal Degradation: The seal around the sensor lens can break down from exposure to harsh chemicals, compromising the waterproof barrier.

- Lens Failure: Hairline fractures on the sensor lens can distort readings and affect the quality of level data.

Careful cleaning and routine calibration ensure that plastic water level sensors, including float level sensors, deliver reliable performance. This maintenance approach protects the sensor from physical damage and guarantees the highest quality of level data for accurate monitoring.

Cost vs. Lifespan: A Financial Breakdown

Choosing the right material for water level sensors involves balancing upfront costs with long-term performance. A financial breakdown helps decision-makers understand the true value of their investment. The initial price is only one part of the equation. The total cost over the sensor's life provides a more complete picture of its financial impact. This analysis ensures the selection of a sensor that offers both quality and economic sense.

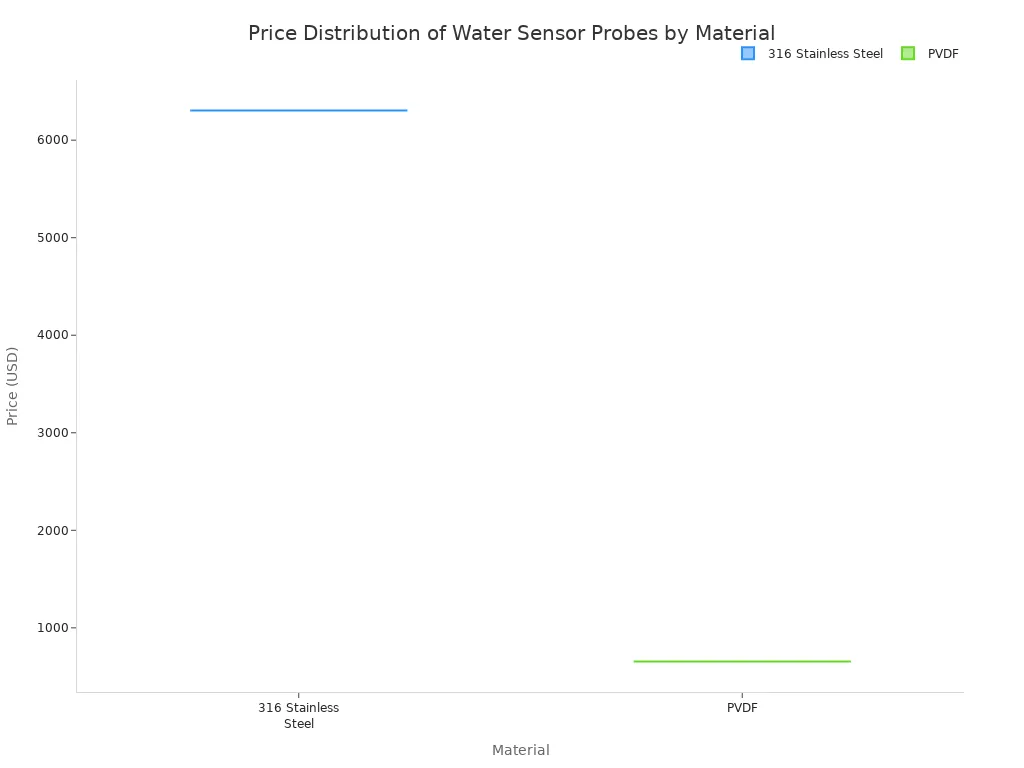

Upfront Costs of Different Materials

The initial purchase price of sensors varies significantly based on the material. Materials like 316L Stainless Steel and PVDF often have a lower entry price point. Titanium and specialty alloys typically cost more. The price reflects the material's manufacturing complexity and corrosion resistance.

| Material | Product Name | Starting Price |

|---|---|---|

| 316L Stainless Steel | UNIK5600 Pressure Sensor | $658.00 |

| Titanium | UNIK5700 Pressure Sensor | $564.20 |

| PVDF | MM Reed Chain Float Level Sensor | $656 |

While some titanium sensors may appear less expensive initially, prices can vary widely depending on the specific model and features. For example, a high-performance titanium sensor for wastewater can be much more expensive.

This variation shows that the application heavily influences the cost. A simple stainless steel sensor for freshwater will be cheaper than a specialized one for industrial use. The key is to match the material quality to the application's demands to achieve the right level of accuracy.

Calculating Total Cost of Ownership

Total Cost of Ownership (TCO) offers a comprehensive view of a sensor's lifetime expense. It looks beyond the initial purchase price. TCO includes all costs associated with the sensor from acquisition to disposal. This calculation provides a better measure of long-term value and helps justify a higher initial investment for a quality product.

A simple formula helps calculate the TCO for water level sensors: TCO = purchase price + installation costs + operating costs + maintenance and repair costs + disposal/replacement costs

A cheaper sensor might require frequent maintenance and early replacement. These recurring costs add up over time. A more durable sensor, like one used in float level sensors, may have a higher upfront price but lower maintenance needs. This leads to a lower TCO and better reliability for level monitoring. Proper data verification can also reduce operational costs by ensuring the level of accuracy.

When to Invest in a Premium Material

Investing in a premium material is a strategic decision. It is necessary when standard materials cannot guarantee longevity or performance. In harsh environments like saltwater or industrial wastewater, a premium material is essential for automation. The cost of sensor failure, including downtime and inaccurate data, often outweighs the higher initial price of a quality sensor.

Consider a premium material for float level sensors when:

- The environment is highly corrosive.

- Sensor failure would lead to significant financial loss or safety risks.

- Maintenance access is difficult or expensive.

- Long-term reliability and optimal performance are critical for automation.

In these cases, materials like Titanium or Hastelloy C provide the best value. Their durability ensures a high level of quality and a long service life. This investment protects the integrity of the level data and the efficiency of the entire system. The right choice ensures the highest level of performance and peace of mind.

The best material for a water sensor probe depends on the water chemistry and budget. Operators achieve the right level of performance with water quality sensors by matching materials to the water. This ensures a high level of accuracy and the correct level of data.

Quick Guide:

- Saltwater: Choose Titanium for the highest level of protection.

- Strong Chemicals: Use PVDF for a high level of resistance.

- Freshwater: 316L Stainless Steel provides a good level of quality.

Investing in the correct water sensor probe from the start ensures the long-term integrity of water level data. Proper water quality sensors maintain a high level of quality.