How to Choose the Right Water Level Sensor for Your Needs

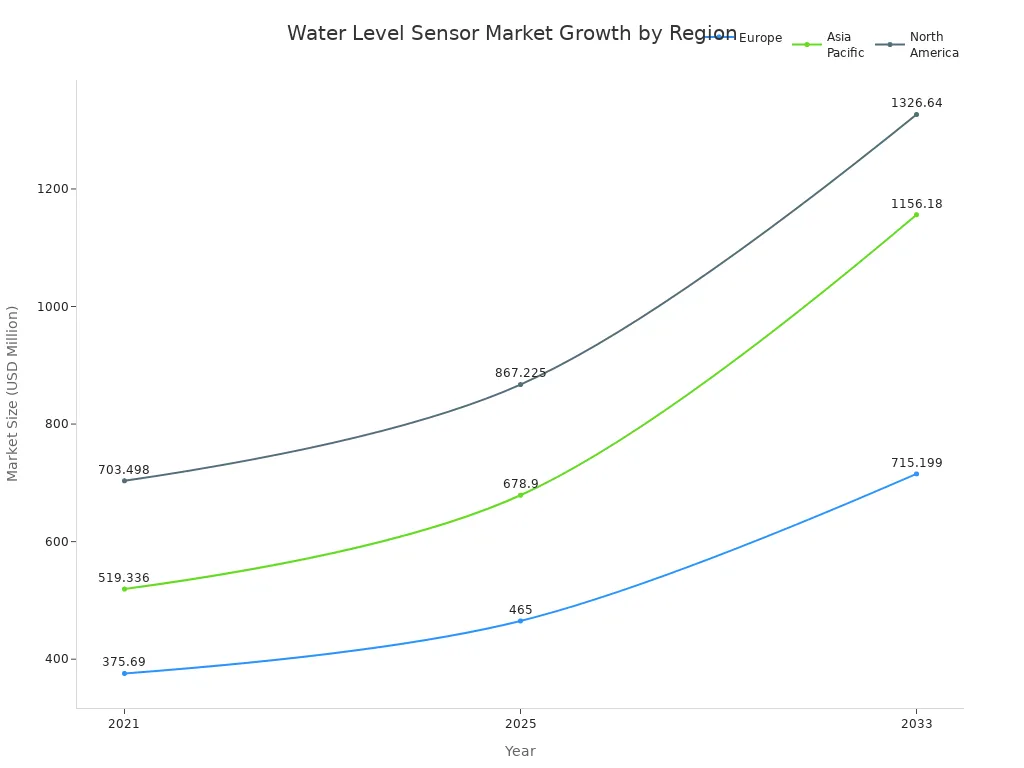

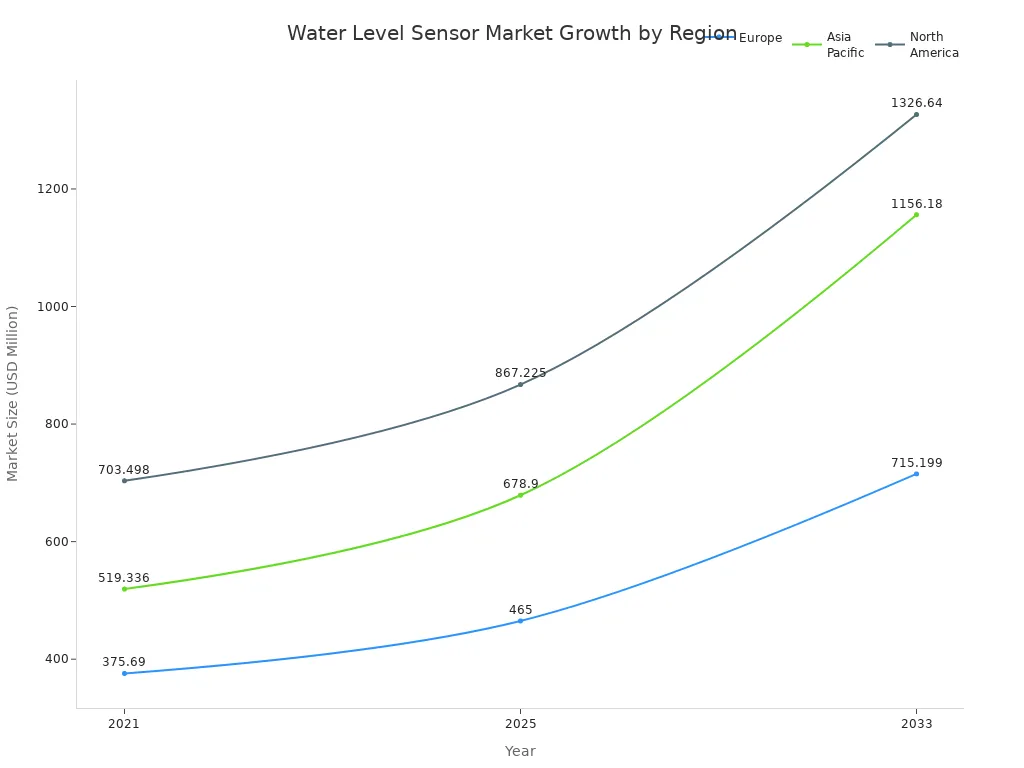

You need to choose a water level sensor that fits your application and environment. The global market for water sensors continues to grow, showing strong demand in Europe, Asia Pacific, and North America.

- In municipal water systems, sensors help you detect leaks and regulate water flow.

- Industrial sites use sensors for real-time water monitoring to prevent overflows.

- Farms rely on accurate water measurement for better irrigation and crop yields.

Matching sensor features to your needs improves monitoring accuracy and ensures reliable water management.

Importance of Water Level Sensors in Different Applications

Why Water Level Sensors Matter

You depend on water level sensors for safe and efficient operations in many settings. These devices help you prevent overflows, leaks, and costly damage. The importance of water level sensors becomes clear when you look at how they protect your property and support daily life. You use them to keep water at the right level in tanks, pools, and reservoirs. They also help you avoid waste and save resources.

You see the importance of water level sensors in many industries. For example, water treatment plants rely on them to monitor tank levels and prevent overflow. Food and beverage producers use them to maintain liquid levels for product quality. Chemical processing plants need them to monitor corrosive substances. The oil and gas industry tracks storage tank inventory to prevent spills. Pharmaceutical manufacturing requires precise measurements for drug production. These examples show how water level sensors work to keep processes safe and efficient.

Common Uses for Water Detection Sensors

You find water detection sensors in many applications. They help you with industrial water monitoring, home safety, and environmental protection. Here are some common places where you use water detection sensors:

- Water treatment plants

- Industrial tanks

- HVAC systems

- Household appliances

- Chemical processing

- Pharmaceutical industry

- Fuel storage

- Food and beverage production

You also use water detection sensors in irrigation systems and for flood detection in basements. They help you monitor soil moisture in agriculture. Many smart home systems use water detection sensors to give you real-time alerts about leaks or flooding. In commercial properties, you use them to protect high-value assets and address leaks quickly, especially near electronics.

The table below shows more specific uses for water detection sensors in different applications:

| Application Type | Specific Uses |

|---|---|

| Wastewater Treatment Facilities | Monitoring influent and effluent flow rates, settling tank levels, chemical treatment processes, and sludge concentration levels. |

| Manufacturing Facilities | Used for cooling system monitoring, process water management, leak detection systems, and environmental compliance monitoring. |

You see that the types of water level sensors you choose depend on your needs. Each type works best in certain situations. When you understand how water level sensors work, you can select the right one for your application. This knowledge helps you improve monitoring and keep your water systems running smoothly.

Identify Your Application and Environment

Define the Purpose of Measurement

Before you choose a water level sensor, you need to know why you want to measure water levels. Each application has different needs. Some sites, like high-velocity rivers or reservoirs, need special sensors. You might want to track water for safety, for real-time monitoring, or for continuous level monitoring. Your budget also matters. Some sensors cost less at first but need more maintenance later. Others cost more but last longer. You should also think about how often you need to check the water. If you need frequent readings, you may need more sensors or a system that supports data redundancy.

Here is a table to help you see what to consider:

| Factor | Description |

|---|---|

| Physical site characteristics | Different sites (e.g., ephemeral streams, high-velocity rivers, reservoirs) have unique sensor needs. |

| Total deployment cost | Budget constraints affect sensor choice; cheaper options may have limitations. |

| Upfront cost vs. operating cost | Consider both initial investment and ongoing maintenance costs when selecting sensors. |

| Ease of maintenance | Non-contact sensors are preferred for safety and ease of maintenance. |

| Data collection requirements | Frequency of readings and staff availability impact sensor selection. |

| Data redundancy | Multiple sensors may be needed to ensure consistent data flow during major events. |

| Ongoing vs. occasional use | The intended frequency of use influences the choice of measurement solution. |

Consider the Installation Location

You need to look at where you will install the sensor. The type of water, such as clean, dirty, or corrosive, changes which sensor works best. Some sensors work better in certain temperatures or pressures. The way you mount the sensor can make installation easier and improve accuracy. You should also think about how easy it is to reach the sensor for maintenance.

- If you have a site with lots of debris or flooding, non-contact sensors work well because they are less likely to get damaged.

- Some locations, like private docks or critical pipes, need sensors placed where you can access them easily.

- You should not just put sensors where you already have them. Look for places that need better monitoring.

- Non-contact sensors need careful calibration and can be affected by vandalism or bad weather.

Assess Environmental Conditions

Environmental conditions can change how well your sensor works. High or low temperatures, humidity, and chemicals in the water can affect the sensor’s life and accuracy. If you have big temperature swings or high humidity, your sensor might not give correct readings. Exposure to chemicals or corrosive substances can damage some sensors. You need to pick a sensor that can handle the conditions at your site. This helps you get reliable results when monitoring liquid levels in all your applications.

Tip: Always check the sensor’s specifications to make sure it fits your water environment. This helps you avoid problems and keeps your liquid level monitoring system working well.

Key Selection Criteria for Liquid Level Sensors

Type of Liquid and Compatibility

You must always consider the type of liquid when choosing water detection sensors. The chemical composition of the liquid affects which materials you should select for your sensor. Some liquids, like potable water, are not harsh. Others, such as wastewater or chemicals, can damage sensors if you do not pick the right materials.

- Chemical compatibility matters most. You need to select materials that can handle the chemicals in your water. This prevents damage and keeps your sensor working longer.

- Material selection depends on a chemical compatibility guide. You should use corrosion-resistant materials for harsh environments. This ensures optimal performance and reliability.

- Environmental conditions, such as temperature, pressure, and UV exposure, also affect how well your sensor materials perform.

- Application requirements, like the type of tank, number of sensing points, and mounting needs, influence your material choice.

- Chemical resistance is crucial for sensors in industries that handle corrosive substances. This property keeps your equipment safe and extends its life.

- Always check the properties of your water before installing a liquid level sensor. This step helps you avoid costly replacements and ensures reliability in your monitoring system.

Note: If you use the wrong material, your sensor may fail early. This can lead to inaccurate measurements and unreliable monitoring.

Measurement Range and Depth

You need to match the measurement range of your water detection sensors to your application. Each site has different requirements for how deep or shallow the water can get. If you choose a sensor with the wrong range, you may not get accurate readings.

| Application Type | Measurement Range |

|---|---|

| General Use | 0-5M water level |

- For most industrial and municipal applications, a range of 0-5 meters covers general needs. If you monitor deeper tanks or reservoirs, you need a sensor with a larger range.

- Always check the maximum and minimum water levels at your site. This helps you select a level sensor for tanks or open bodies of water that fits your needs.

- If you use a sensor outside its range, you risk losing reliability and getting poor data.

You should also consider the shape and size of your tank or reservoir. Some water detection sensors work better in narrow tanks, while others suit wide or irregular shapes. Matching the sensor to your tank ensures reliable liquid level measurement and monitoring.

Required Accuracy and Resolution

You want your water detection sensors to give you accurate measurements. The accuracy and resolution of your sensor affect how well you can monitor water levels. High accuracy is important for applications where small changes in water level matter, such as in chemical processing or pharmaceutical production.

- Choose a sensor with the right resolution for your needs. If you need to detect small changes, pick a sensor with high resolution.

- Reliable sensors help you avoid errors in liquid level detection. This is important for safety and for meeting industry standards.

- Some applications, like irrigation or wastewater treatment, may not need the highest accuracy. Others, such as laboratory or food production, require precise and reliable monitoring.

Tip: Always check the sensor’s specifications for accuracy and resolution. This helps you meet your monitoring goals and ensures the reliability of your liquid level monitoring system.

You should use these selection criteria for water detection sensors to guide your decision. When you match the sensor to your liquid type, measurement range, and accuracy needs, you improve the reliability of your monitoring system. This approach helps you achieve accurate measurement and keeps your water systems running smoothly.

Installation Requirements

When you install water detection sensors, you need to think about the type of sensor and the place where you will use it. Each sensor type has its own needs and limits. You want to make sure your sensor works well and lasts a long time. The table below shows common installation requirements and constraints for different water level sensors:

| Sensor Type | Installation Requirements | Constraints |

|---|---|---|

| Conductive | Monitor for buildup; use Teflon or polyethylene coatings for easier maintenance. | Needs regular cleaning because buildup can affect readings. |

| Capacitance | Can handle high temperatures and pressures; coatings help reduce buildup. | Probes must reach the bottom of tall tanks, which can cause tension or breakage. Static charge can be a problem. |

| Ultrasonic | Consider temperature and humidity in the area. | Dust, fog, and particles can affect accuracy; needs regular maintenance. |

You should always check the environment before installing water detection sensors. If you use a sensor in a tank with a lot of debris, you may want to install it above the bottom to avoid buildup. Some sensors need to be coated to protect them from chemicals in the water. You also need to make sure you can reach the sensor for cleaning and repairs. If you install sensors in hard-to-reach places, you may have trouble with maintenance later.

Tip: Plan your installation so you can remove and clean the sensor easily. This helps you keep your monitoring system working well.

Output Signal and System Integration

You need to think about how your water detection sensors will send data to your monitoring system. The type of output signal affects how you connect the sensor to your equipment. Most modern systems use either analog or digital signals. The table below shows the main types of signals and how they work with today’s systems:

| Signal Type | Description | Compatibility with Modern Systems |

|---|---|---|

| Analog Signals | Continuous signals (like 4-20 mA) that show the measured water level. | Good for real-time feedback; used in many applications. |

| Digital Signals | Discrete data that is easy to connect to digital equipment. | Works well with new digital and smart systems. |

You can also choose between analog transmitters and digital (smart) transmitters:

| Transmitter Type | Description | Features for Modern Systems |

|---|---|---|

| Analog Transmitters | Give a steady output signal, usually 4-20 mA. | Reliable for real-time monitoring. |

| Digital (Smart) Transmitters | Use advanced technology and digital protocols. | Allow self-checks and connect to IoT systems. |

When you pick a liquid level sensor, you should match the output signal to your monitoring system. If you use a smart building or factory, digital signals may work best. If you need simple, real-time feedback, analog signals are a good choice. Always check if your system can read the signal from your water detection sensors before you buy.

Note: The right output signal makes it easier to track water levels and spot problems quickly.

Maintenance and Durability

You want your water detection sensors to last a long time and give you accurate readings. Good maintenance and strong materials help you reach this goal. Here are some best practices for keeping your sensors in top shape:

- Pick sensors made from materials that resist corrosion and match the chemicals in your water.

- Check your sensors often for signs of wear, rust, or damage.

- Use weighted sensors or cages to keep them in place at the bottom of tanks.

- Place sensors a little above the tank bottom to avoid dirt and sediment.

- Protect vent tubes with filters and avoid sharp bends in cables to stop moisture from getting in.

- Secure cables with clamps and guides to prevent rubbing from moving water.

- Make sure you can remove sensors easily for cleaning and checks.

- Clean your sensors every few months to remove buildup and check for moisture in vent lines.

If you follow these steps, your water detection sensors will work better and last longer. You will get more reliable data for your monitoring needs. Strong and well-maintained sensors help you avoid costly repairs and keep your water systems safe.

Remember: Regular cleaning and inspections help you catch problems early and keep your liquid level sensors working well.

Comparison of Water Level Sensor Types

When you choose a level monitoring system, you need to understand the key types of water detection sensors. Each type works differently and fits certain applications. This section compares float, ultrasonic, and radar sensors. You will see how each sensor helps with water monitoring and what makes them unique.

Float Water Level Sensors

Float sensors are one of the oldest and most common types of liquid level sensors. You find them in many tanks and containers. These sensors use a float with a magnet inside. When the water rises or falls, the float moves. This movement triggers a magnetic reed switch outside the tank.

How Float Sensors Work:

- The float sits on the water surface.

- As the water level changes, the float moves up or down.

- The magnet inside the float activates a switch, sending a signal to your level monitoring system.

Advantages:

- Simple design makes them easy to use.

- Low cost means you can install them in many places.

- Reliable for basic water level detection.

Disadvantages:

- You must install them in a specific way.

- They may not work well in tanks with debris or thick liquids.

- Moving parts can wear out over time.

Note: You should check the placement of your float sensor. If you install it incorrectly, you may get wrong readings. Regular checks help you keep your level monitoring system accurate.

Typical Accuracy and Reliability:

- You measure accuracy by comparing the sensor output to a known water level.

- Resolution shows the smallest change the sensor can detect.

- Calibration helps match the sensor reading to the real water level.

- Interference from outside sources can affect readings.

- Newer float sensors use digital processing to improve accuracy.

Cost Range:

| Sensor Type | Price Range |

|---|---|

| Float Level Sensors | $50 - $300 |

You often use float sensors for simple water monitoring in tanks, wells, and reservoirs. They work well for many home and industrial uses.

Ultrasonic Water Level Sensors

Ultrasonic liquid level sensors use sound waves to measure the distance from the sensor to the water surface. You do not need to touch the water. This makes them good for tanks with chemicals or dirty water.

How Ultrasonic Sensors Work:

- The sensor sends out a sound wave.

- The wave bounces off the water surface and returns to the sensor.

- The sensor measures the time it takes for the wave to return.

- Your level monitoring system uses this time to calculate the water level.

Advantages:

- Non-contact design means no moving parts.

- You can use them with many types of water and tanks.

- Good for monitoring in open tanks or places with harsh liquids.

Disadvantages:

- Temperature and pressure changes can affect readings.

- Dust, fog, or foam on the water can block sound waves.

- You must install them above the water, not inside it.

Common Failure Modes:

| Failure Mode | Description | Cause | Solution |

|---|---|---|---|

| Electromagnetic interference | Data fluctuates or no signal | Motors and electrical equipment nearby | Grounding and isolation |

| Liquid agitation | No signal or data fluctuations | Unstable water surface | Use a larger range sensor or waveguide |

| Foam on liquid surface | Sensor keeps searching or wave loss | Foam absorbs sound waves | Install a waveguide or use radar sensors |

| High temperature | Measurement fails | Steam or mist weakens sound waves | Use special probes or increase sensor range |

| Blind zone issues | Arbitrary data appears | Sensor's blind zone too close to water | Install sensor higher above the water |

Tip: If you have foam or steam above your water, you may want to use radar sensors instead. This helps you keep your level monitoring system reliable.

Cost Range:

| Sensor Type | Price Range |

|---|---|

| Ultrasonic Level Sensors | $200 - $1,000 |

You often use ultrasonic sensors for water monitoring in open tanks, sumps, and wastewater plants. They work well when you need a non-contact solution.

Radar Water Level Sensors

Radar liquid level sensors use microwave signals to measure the distance to the water surface. You do not need to touch the water. These sensors work well in tough environments, such as places with dust, steam, or high humidity.

How Radar Sensors Work:

- The sensor sends out a microwave signal.

- The signal bounces off the water surface and returns.

- The sensor measures the time for the signal to return.

- Your level monitoring system uses this to find the water level.

Advantages:

- High accuracy, even in harsh conditions.

- No need for calibration in most cases.

- Works well with dirty water, steam, or dust.

Disadvantages:

- Higher cost than other sensors.

- High humidity can weaken radar signals.

- Condensation on the sensor can cause errors.

- Electronic parts may corrode in wet places.

Note: You should protect radar sensors from condensation and high humidity. This helps you keep your level monitoring system working well.

Cost Range:

| Sensor Type | Price Range |

|---|---|

| Radar Level Sensors | $500 - $2,000+ |

You use radar sensors for water monitoring in reservoirs, rivers, and industrial tanks. They work best when you need high accuracy and must deal with tough environments.

Comparison Table:

| Sensor Type | Operating Principle | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Float Sensors | Magnet inside float triggers reed switch | Economical, simple, reliable | Limited installation, moving parts | Water level detection in containers |

| Ultrasonic | Sound waves measure distance to water surface | Non-contact, versatile | Affected by foam, temp, pressure | Water monitoring in open tanks |

| Radar | Microwave signals measure distance to water surface | Accurate, no calibration needed | Expensive, affected by humidity | Monitoring in harsh environments |

Remember: You should match the sensor type to your water, tank, and monitoring needs. This helps you build a strong level monitoring system for your site.

Capacitive Water Level Sensors

Capacitive water level sensors help you measure liquid levels by detecting changes in electrical capacitance. You place these sensors inside or outside a tank. When the water level changes, the capacitance between the sensor’s electrodes changes too. Your monitoring system reads this change and tells you the water level.

You often use capacitive sensors in places where you need to avoid moving parts. These sensors work well with clean water, wastewater, and even some chemicals. You can use them in tanks, pipes, and open channels.

Key Features of Capacitive Sensors:

- No moving parts, so you get less wear and tear.

- You can use them for continuous level measurement.

- They work with many types of liquids, including corrosive ones.

Sensitivity and Response Time

Capacitive sensors can react quickly and give you accurate readings. Some designs, like the helical electrode sensor, offer very high sensitivity and fast response times. The table below shows how different designs compare:

| Sensor Type | Sensitivity Improvement | Response Time Improvement (s) |

|---|---|---|

| Helical Electrode Sensor | > 99.99% | 27.73 (vs. cylindrical) |

| 6.46 (vs. parallel rod) | ||

| Cylindrical Sensor | N/A | N/A |

| Parallel Rod Sensor | N/A | N/A |

You can also find capacitive pressure sensors that stabilize in just 55 milliseconds under load. After you remove the load, they recover in 42 milliseconds. This means you get almost instant feedback when the water level changes.

Tip: If you need fast and sensitive water level detection, capacitive sensors with advanced electrode designs can help you get reliable results.

Pros:

- High sensitivity and fast response.

- Good for continuous monitoring.

- Suitable for many liquids, including some chemicals.

Cons:

- Sensor readings can change if the liquid’s properties change.

- You may need to calibrate the sensor for each new liquid type.

- Build-up on the sensor can affect accuracy.

You can use capacitive water level sensors in industrial tanks, water treatment plants, and even in some home systems. They give you a good balance of speed, accuracy, and durability.

Pressure Water Level Sensors

Pressure water level sensors help you measure how deep the water is by sensing the pressure at the bottom of a tank or well. You place the sensor at the lowest point you want to measure. The sensor converts the water pressure into an electrical signal. Your system then calculates the water level from this signal.

You often use pressure sensors in deep wells, reservoirs, and underground tanks. These sensors work well when you need to measure large changes in water depth.

Key Features of Pressure Sensors:

- You can use them for both shallow and deep water.

- They work well in closed tanks and open bodies of water.

- You get accurate readings even in harsh environments.

Typical Pressure Ranges for Deep Wells:

- The PT-500 submersible pressure transducer measures up to 200 PSI. This lets you monitor depths over 450 feet.

- The SLS300D Submersible Deep Well Level Sensor covers a range of 0-300 meters, which is about 0-600 PSI.

Note: You should choose a sensor with a pressure range that matches your well or tank depth. This helps you avoid sensor overload and keeps your readings accurate.

Pros:

- Reliable for deep water measurement.

- Durable and resistant to harsh conditions.

- Simple installation in most tanks and wells.

Cons:

- Sensor readings can drift if the vent tube gets blocked.

- You need to protect cables and vent tubes from damage.

- Sediment or debris can affect sensor accuracy if not installed properly.

You can use pressure water level sensors in irrigation wells, municipal water systems, and industrial tanks. They give you strong performance for both shallow and deep water monitoring.

Optical Water Detection Sensors

Optical water detection sensors use light to sense the presence or absence of water. You place the sensor where you want to detect leaks or monitor water levels. When water touches the sensor tip, the light path changes. The sensor then sends a signal to your monitoring system.

You often use optical sensors for leak detection, overfill alarms, and in places where you need fast response. These sensors work well in clean water, but you can also use them in some industrial settings.

Detection Limits and Response Times:

- You can detect water concentrations from 1 to 70 mg/L.

- The sensor responds in just 20 milliseconds.

- Some optical sensors have a response time of 0.5 seconds.

Tip: Optical sensors give you almost instant alerts when water is present. This makes them great for leak detection and emergency shut-off systems.

Optical sensors have become more important in recent years. You see them used in healthcare, climate science, and industrial monitoring. Advances in optical technology now let you monitor water and humidity in real time.

Pros:

- Very fast response time.

- High sensitivity to small amounts of water.

- No moving parts, so you get long life and low maintenance.

Cons:

- Dirt or film on the sensor can block the light and cause false readings.

- You may need to clean the sensor tip often in dirty environments.

- Not ideal for measuring large changes in water level.

You can use optical water detection sensors in data centers, server rooms, laboratories, and smart home systems. They help you catch leaks early and protect your equipment from water damage.

Pros, Cons, and Best-Use Cases for Water Level Sensors

Float Sensors: Advantages and Limitations

Float water detection sensors give you a simple way to track water levels. You can install them easily, and they work well in many tanks. These sensors use a float that moves with the water. When you need basic monitoring, float sensors often do the job.

Here is a quick look at their main strengths and weaknesses:

| Advantages of Float Sensors | Disadvantages of Float Sensors |

|---|---|

| Simplicity and reliability | Not suitable for turbulent fluids or vibrations |

| Easy installation and low maintenance | Cannot measure non-conductive or non-liquid materials |

| Effective in harsh conditions and with thick or corrosive liquids | Limited applicability in certain scenarios |

You get the best results from float water detection sensors in calm tanks or reservoirs. They handle thick or corrosive liquids well. If your site has a lot of movement or vibration, you may want to choose another type for more reliable monitoring.

Ultrasonic Sensors: Advantages and Limitations

Ultrasonic water detection sensors use sound waves for non-contact monitoring. You do not need to touch the water, which helps in dirty or hazardous places. These sensors give you continuous and accurate readings.

You should use ultrasonic sensors when you need:

- Monitoring river levels

- Strategic installation on bridges

- Urban water management

- Continuous monitoring with high accuracy

- Leak detection and flood prevention

Ultrasonic water detection sensors work best for open tanks, rivers, and places where you want to avoid contact with the water. They help you with real-time monitoring and quick response to changes. However, dust, foam, or temperature swings can affect their accuracy. You may need to check and clean them to keep your monitoring system working well.

Tip: Use ultrasonic sensors for water detection in places where you need fast, non-contact monitoring and where the environment stays mostly clear.

Radar Sensors: Advantages and Limitations

Radar water detection sensors use microwaves for monitoring. You get high accuracy, even in tough environments. These sensors work well when you need to measure water levels in reservoirs, rivers, or tanks with steam or dust.

However, radar sensors have some limits:

| Limitation Description | Source |

|---|---|

| Echoes form when material sticks to the probe or antenna, causing incorrect measurements | Holy Kell |

| Guided Wave Radar has a limited range (up to 30m) due to waveguide rod constraints | Current Instrument |

| Rod-shaped probes can collect buildup and need cleaning | Mac Sensor |

You should use radar water detection sensors for monitoring in places with steam, dust, or changing weather. They give you reliable results when other sensors may fail. You need to clean the probes sometimes to keep your monitoring accurate.

Note: Radar sensors help you with water detection and monitoring in harsh conditions, but you must maintain them for the best results.

Capacitive Sensors: Advantages and Limitations

You can use capacitive water detection sensors for many types of monitoring. These sensors measure changes in electrical capacitance to detect water levels. You do not need moving parts, so you get less wear and tear. Capacitive sensors give you fast and sensitive readings, which helps you track water changes quickly.

Advantages:

- You get high sensitivity and quick response for real-time monitoring.

- You can use them with many liquids, including water and chemicals.

- No moving parts means less maintenance and longer life.

- You can install them inside or outside tanks for flexible monitoring.

Limitations:

- The sensor’s readings can change if the water’s properties change.

- You may need to calibrate the sensor for each new liquid.

- Buildup on the sensor can affect accuracy, so you need to clean it sometimes.

You find capacitive water detection sensors in many industries. The table below shows some best-use cases:

| Industry | Use Case Description |

|---|---|

| Automotive | Monitoring fuel levels in tanks, ensuring accurate measurement and safety compliance. |

| Industrial Processes | Monitoring fluid levels in tanks and pipelines, optimizing processes, and preventing spills or overflows. |

| Consumer Products | Precise water level monitoring in washing machines and coffee makers for optimal performance. |

| Medical Devices | Monitoring fluid levels in infusion pumps and diagnostic equipment for accurate medication delivery. |

| Environmental Monitoring | Measuring fluid levels in reservoirs and water treatment systems for resource management and flood control. |

| Agriculture | Monitoring fluid levels in irrigation systems and storage tanks to optimize resource management. |

Tip: You should use capacitive water detection sensors when you need fast, reliable monitoring in tanks, pipelines, or even home appliances.

Pressure Sensors: Advantages and Limitations

Pressure water detection sensors help you measure water depth by sensing pressure at the bottom of a tank or well. You get accurate and reliable monitoring for both shallow and deep water.

Advantages:

- You get high accuracy and precision for reliable monitoring.

- You can use them in many industries, from water treatment to agriculture.

- You can monitor water remotely, which saves time and reduces manual checks.

- No moving parts means low maintenance.

- Over time, these sensors can be cost-effective for water level monitoring.

Limitations:

- These sensors do not work well with gases.

- Extreme temperatures and pressure changes can affect readings.

- You need to calibrate them sometimes to keep monitoring accurate.

- Installation can be tricky and may affect performance.

- Foaming liquids can make it hard to get correct readings.

Note: You should check your pressure water detection sensors often and follow the manufacturer’s instructions for calibration and installation.

Optical Sensors: Advantages and Limitations

Optical water detection sensors use light to sense water presence. You get very fast response times, which is great for leak detection and emergency monitoring.

Advantages:

- You get instant alerts when water is present.

- High sensitivity lets you detect even small amounts of water.

- No moving parts means long life and low maintenance.

Limitations:

- Environmental conditions, like bending the sensor cable, can lower sensitivity.

- Building these sensors is complex and needs careful splicing.

- Glass fibers can break easily, especially at the sensor tip.

- Dirt or film on the sensor can block light and cause false readings.

Tip: You should use optical water detection sensors for quick leak monitoring in clean environments, such as data centers or labs. Handle them with care to avoid breakage.

Decision-Making Checklist for Choosing Water Level Sensors

Step-by-Step Selection Guide

You want to make the right choice when picking water level sensors for your monitoring needs. Follow these steps to help you with your selection:

- Decide if you need a non-contact sensor. Some sites require sensors that do not touch the water, especially for safety or when the liquid is hazardous.

- Think about how often you need data. If you want continuous monitoring, choose sensors that can send real-time updates.

- Identify the exact application. Are you monitoring a tank, a river, or a well? Each situation may need a different sensor.

- Look at the environment where you will install the sensor. Check for temperature swings, humidity, or chemicals that could affect performance.

- Set your budget. Some sensors cost more but last longer or need less maintenance. Balance your needs with what you can spend.

Tip: Write down your answers for each step. This helps you compare options and find the best fit for your monitoring system.

Quick Reference Table

Use this table to quickly compare the most important criteria for water level sensor monitoring:

| Criteria | Description |

|---|---|

| Understanding the Liquid Characteristics | Make sure the sensor materials match the water’s chemical properties. |

| Measurement Range and Accuracy | Pick a sensor that fits your tank size and monitoring needs. |

| Application Environment | Think about tank shape and outside conditions that could change how the sensor works. |

| Ease of Installation and Maintenance | Choose sensors that are simple to install and easy to keep clean for better monitoring. |

| Output Compatibility | Check that the sensor works with your current monitoring system and uses common outputs. |

You can use this checklist every time you plan a new monitoring project. Careful planning helps you avoid problems and keeps your water level sensors working well.

You can choose the best water level sensor by following a few clear steps. First, think about your water application and environment. Next, match the features of water level sensors to your needs. Always check the type of water, the measurement range, and the accuracy you want. Use the checklist to compare options. When you select the right sensor, you keep your water safe and your system running well.

FAQ

What is the best water level sensor for outdoor use?

You should choose radar or ultrasonic sensors for outdoor use. These sensors handle rain, dust, and changing weather well. Radar sensors work best in harsh conditions. Always check the sensor’s protection rating before you install it outside.

How often should you clean your water level sensor?

You should check and clean your sensor every few months. If you use the sensor in dirty water or tanks with debris, clean it more often. Regular cleaning helps you get accurate readings and keeps your sensor working longer.

Can you use one sensor for different liquids?

You can use some sensors for different liquids, but you must check chemical compatibility. Capacitive and pressure sensors often work with many liquids. Always read the manufacturer’s guide to make sure the sensor material matches your liquid.

What does sensor accuracy mean?

Sensor accuracy tells you how close the sensor’s reading is to the real water level. High accuracy means you get reliable data. You should pick a sensor with the right accuracy for your needs. For example, labs need higher accuracy than garden tanks.

Do water level sensors need special wiring?

Most sensors use standard wiring, but some digital sensors need special cables or connectors. You should follow the installation guide. If you connect the sensor to a smart system, check if you need extra adapters or power supplies.

Tip: Always ask your supplier if you have questions about wiring or installation.