LP Gas Tank Level Gauges Compared: The Industrial Guide to Bluetooth vs. Wi-Fi vs. Ultrasonic Sensors

The propane industry runs on margins, and those margins are often lost in a haze of guesswork. You know the scenario: a site calls with a near run-out panic, forcing a costly emergency delivery. Or, just as bad, you send a driver out for a scheduled drop only to find the tank is still at 60%—that’s what we call a "bad drop", and in my experience, those wasted miles and man-hours can easily cost upwards of $60 per failed delivery.

The old mechanical dial gauge—reliable for safety, but lousy for logistics—simply can't cut it in the era of IoT efficiency. The solution is remote monitoring, but the market is flooded with consumer-grade devices talking Bluetooth, Wi-Fi, or relying on finicky ultrasonic readings.

Here’s the Bottom Line Upfront: For professional, commercial, and industrial LP gas applications, the question isn't if you should monitor, but how you should connect. Hall Effect Sensors (R3D-compatible) combined with Cellular or LoRaWAN connectivity offer the highest reliability, accuracy, and crucially, the Intrinsically Safe (IS) certification required for hazardous environments.

In this guide, we’re going beyond the marketing brochures. We’re going to compare the core technologies on what truly matters to your bottom line: accuracy, safety compliance, and Total Cost of Ownership (TCO).

Core Propane Tank Level Measurement Technologies: The Science of Sensing

When we talk about modern LP gas monitoring, we're really talking about two things: the sensor itself (how it reads the level) and the telemetry (how it sends the data). It’s critical to get the sensing mechanism right, as that determines the foundation of your data quality.

1. Magnetic Hall Effect Readers (R3D/Gauge Reader): The Industry Standard

What I've found over the years is that the best solution is often the one that leverages the most reliable component already in place. For nearly every ASME-certified industrial propane tank, that component is the mechanical float gauge.

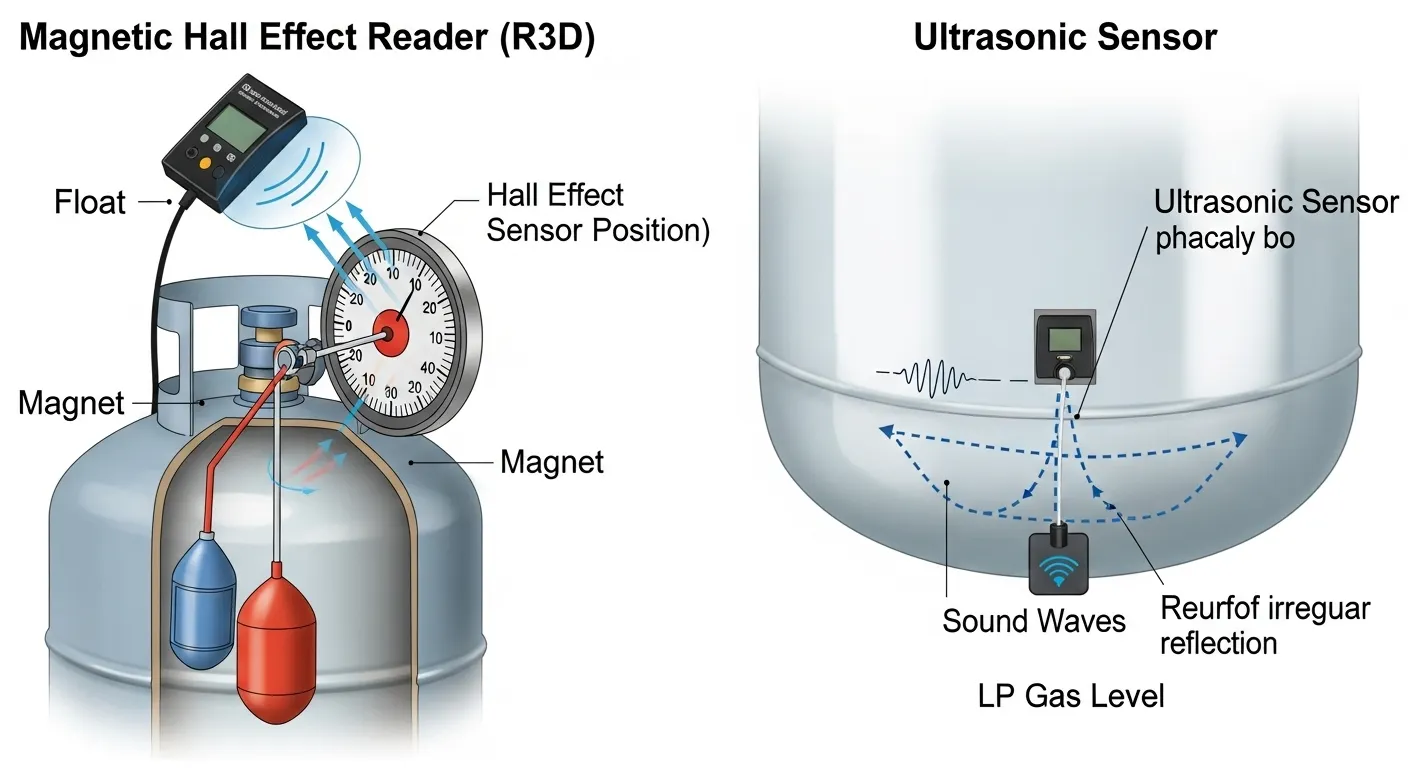

How the Hall Effect Sensor Works

The Hall Effect sensor is the current king of professional LP tank monitoring because it’s a non-invasive retrofit.

- The Float: Inside your tank, a mechanical arm with a float rises and falls with the liquid propane level.

- The Magnet: This arm is mechanically linked to a rotary gauge on the outside of the tank's face, where a magnet is attached to the needle mechanism.

- The Reader: The electronic sensor unit (the monitor) is simply placed over the face of the dial. It contains a Hall Effect sensor, which is a transducer that varies its output voltage in response to a magnetic field. As the needle’s magnet rotates, the Hall sensor reads the changing magnetic field strength and translates that proportional voltage back into a precise percentage level.

This setup offers two huge advantages: reliability and robustness. It never touches the propane, it isn't dependent on sound waves, and it leverages the certified mechanical gauge that is already legally required and engineered to withstand pressure and corrosion. This is why it’s the preferred industrial standard.

2. Ultrasonic Sensors (Non-Invasive): The Accuracy Trade-Off

Ultrasonic sensors are popular in the consumer space, particularly for smaller tanks, because they are incredibly easy to install—you simply stick them on the underside of the tank.

How Ultrasonic Sensing Works

The ultrasonic sensor emits a pulse of high-frequency sound waves. This pulse travels through the metal wall of the tank, through the liquid propane, and reflects off the liquid surface back to the sensor. The sensor measures the time-of-flight (TOF) and calculates the distance based on the speed of sound through the medium.

Here’s what most suppliers won’t tell you: While claim $\pm 1\%$ accuracy in a controlled lab, real-world accuracy suffers due to two primary factors:

- Temperature Dependence: The speed of sound through the liquid propane changes dramatically with temperature. Without flawless internal temperature compensation (which is computationally expensive and battery-draining), a large temperature swing can throw off your readings by several percentage points.

- Tank Geometry and Surface Prep: The sensor needs a flat, clean surface to couple with the tank wall. Any rust, paint chips, or sludge at the bottom of the tank can scatter the sound wave, leading to inconsistent or wildly inaccurate readings. The bottom of an ASME tank is curved, not flat, which further complicates precise measurements.

3. Pressure Sensors & Load Cells: The High-Precision Alternatives

For certain, high-stakes applications, neither R3D nor Ultrasonic is sufficient.

- Load Cells (Weight-Based): Load cells or scales measure the actual weight of the tank and its contents. Since propane volume is sold by mass in many jurisdictions, this is the most accurate method, completely independent of temperature. However, it requires placing the entire tank on a certified scale, making it impractical and prohibitively expensive for most permanent installations. It’s typically reserved for small cylinders or precision custody transfer.

- Pressure Sensors: Since propane is stored as a liquid-gas mix, the pressure inside the tank is directly related to the temperature, not the volume (until the tank is nearly empty). This makes pure pressure sensing irrelevant for level measurement in bulk tanks.

Connectivity Face-Off: Bluetooth vs. Wi-Fi vs. Cellular/LoRa

The sensor determines what you read; the connectivity determines when and where you read it. For industrial remote tank monitoring, the communication method is arguably the most important choice because it determines your operational reach.

Bluetooth Low Energy (BLE): The Proximity Trade-Off

Bluetooth monitors are the entry-level option and are fantastic for local, simple applications.

- Pros: Very low hardware cost, extremely low power consumption (batteries can last years), and straightforward setup.

- Cons: Range is the killer. In a factory setting or on a commercial property, the signal range is typically limited to 50-100 feet in line of sight, and less once it passes through walls or metal structures.

- The Reality Check: BLE monitors are useful for a homeowner checking their tank via a smartphone app while standing right next to it. For a logistics manager trying to monitor 500 tanks across three states, Bluetooth is functionally useless unless you invest in a complex network of Wi-Fi Bridges or Gateways to relay the signal to the internet. This adds cost, complexity, and several new points of failure.

Wi-Fi: High Bandwidth, High Power Draw

Wi-Fi offers the bandwidth to send large chunks of data quickly, but this is overkill for a simple level percentage.

- Pros: Utilizes existing infrastructure (no new data plan needed), and easily integrates with existing network monitoring tools.

- Cons: Power Consumption. Wi-Fi is a power hog. While a BLE sensor can run for 5-7 years on a single battery pack, a Wi-Fi-only sensor would drain its battery in weeks or months, meaning frequent, costly maintenance visits. This makes battery replacement a serious maintenance cost and a substantial soft cost in your TCO analysis.

- Installation Hurdles: You have to rely on a strong, un-congested Wi-Fi signal at the tank location. On the periphery of a plant or behind a metal enclosure, Wi-Fi dead zones are rampant, leading to unreliable data transmission.

Cellular & LoRaWAN: The Industrial Telemetry Standard

If your goal is delivery optimization and remote asset management, cellular (4G LTE, NB-IoT, Cat-M1) and LoRaWAN (Low Power Wide Area Network) are the only viable solutions.

- The Power of LoRaWAN/Cellular: They do not require an existing Wi-Fi network. They simply connect directly to a dedicated network. Cellular uses established wireless carrier infrastructure, while LoRaWAN uses low-power, long-range private or public networks ideal for transmitting small packets of data (like a tank percentage) over many miles.

- The ROI Driver: These technologies enable proactive, just-in-time delivery. Your system receives a data report (often multiple times per day) that feeds directly into your ERP or dispatch software, allowing the system to flag a tank at the 20% optimal refill threshold and automatically generate a route.

- The Subscription Reality: The trade-off is the recurring data subscription cost. This is the key difference from the upfront cost models of Wi-Fi or Bluetooth. However, the cost of one emergency delivery often outweighs a year's worth of subscription fees for a cellular monitor.

In my 15 years in this space, I've found that the single greatest financial driver for remote tank monitoring is the shift from reactive or scheduled delivery to proactive, just-in-time delivery. This is only possible with a robust cellular or LoRaWAN solution.

Critical Comparison: Accuracy, Safety, and Total Cost of Ownership (TCO)

Choosing the right technology for your operation requires a disciplined evaluation of three non-negotiable factors.

Accuracy and Environmental Factors

For inventory management and commercial custody transfer, precision is everything. This is where the R3D Hall Effect technology shines.

| Feature | Hall Effect (R3D) | Ultrasonic Sensor |

| Measurement Principle | Reads the calibrated mechanical float position. | Measures Time-of-Flight (TOF) of sound wave. |

| Susceptibility to Temp. | Low. Measures mechanical position, not gas physics. | High. Speed of sound varies dramatically with temperature. Requires complex compensation. |

| Tank Geometry Impact | Minimal. Uses the tank's certified internal float mechanism. | High. Affected by internal geometry, sediment, and curved tank bottom. |

| Typical Industrial Acc. | $\pm 1\%$ of full scale. | $\pm 3\%$ (real-world, non-compensated) |

When you’re dealing with thousands of gallons, a $3\%$ error isn't a rounding mistake—it’s a financial discrepancy. This is why the Hall Effect sensor—a contact sensor that interfaces with a robust internal mechanical float—remains the most trusted technology for continuous-level monitoring in the industry.

We must also touch on Temperature Compensation. Propane, like any liquid, expands and contracts significantly with temperature. A full tank read at $100^{\circ}\text{F}$ actually holds less mass (and usable energy) than a full tank at $40^{\circ}\text{F}$. NIST Handbook 44, which governs commercial weighing and measuring devices, mandates that meters used for retail sale must account for this temperature change. While a remote monitor isn't a custody transfer device, the best R3D cellular monitors incorporate a thermometer to provide a compensated volume reading—a critical feature for any distribution company serious about inventory accuracy.

The Mandate of Safety: Intrinsically Safe (IS) Certification

This is the non-negotiable filter. If the device does not have an Intrinsically Safe (IS) certification, you cannot legally or safely deploy it on a commercial or industrial LP gas tank. Period.

- The Danger: An LP tank is in a hazardous location (often classified as a Zone 1 or Division 1 area). Any electrical device deployed here, including a sensor, must be designed so that its electrical and thermal energy is too low to cause an ignition of the surrounding gas mixture, even under fault conditions. A standard consumer Wi-Fi or Bluetooth device generates sparks or heat that can ignite propane vapor.

- The Standard: You must look for globally recognized certifications like ATEX (European Union) or IECEx (International Electrotechnical Commission System). In North America, UL/FM certifications for hazardous locations also apply.

- Trustworthiness Insight: Most low-cost, off-the-shelf ultrasonic or Bluetooth monitors fail this test. You must use equipment specifically designed and certified for explosive atmospheres. The initial cost is higher, but it protects your people, your facility, and your company from catastrophic liability.

ROI & Total Cost of Ownership (TCO)

The ultimate evaluation of an LP gas gauge technology is its TCO, which is the purchase price plus installation, maintenance, and subscription costs, minus the operational savings it generates.

TCO Breakdown:

- Hardware & Installation (CAPEX):

- Bluetooth/Wi-Fi: Low hardware cost. Installation is easy (stick/clip-on).

- Cellular/LoRa: Moderate to high hardware cost due to IS certification, robust casing, and modem. Installation is a quick retrofit onto the R3D dial.

- Network & Subscription (OPEX):

- Bluetooth/Wi-Fi: Zero or near-zero subscription fee, but often requires costly Gateway/Bridge hardware to achieve remote monitoring.

- Cellular/LoRa: Mandatory annual or monthly data subscription. This is the main recurring expense.

- Maintenance & Soft Costs (OPEX):

- Wi-Fi: High cost due to frequent battery replacement and IT time spent troubleshooting network connection issues.

- Cellular/LoRa: Low cost. The low-power modems ensure a battery life of 5-10 years, minimizing maintenance trips and maximizing data uptime.

The Justification: If your delivery cost is $60 and a cellular monitor prevents just three bad drops or one emergency delivery per year for a tank, the monitor has already paid for its annual subscription and contributed significantly to its own purchase price ROI. The operational efficiencies, as detailed in reports by the Manufacturing Institute, are why the IoT monitoring market is projected to continue its high growth trajectory.

Implementation & Strategy: Turning Data into Profit

The technology is merely a tool. The real profit is realized when you integrate that tool into your operational strategy.

The 'Just-in-Time' Delivery Revolution

The most effective strategy employed by leading distributors is the shift from scheduled to predictive delivery.

- The 20% Rule: By automatically receiving level data via cellular telemetry, you can set an alert threshold—the industry consensus is typically around 20%—that automatically triggers a delivery ticket. This ensures you always have a buffer against unexpected consumption spikes and drastically reduces the risk of run-outs.

- Route Optimization: The dispatching software now sees a dynamic list of tanks needing attention, allowing the system to use sophisticated algorithms to cluster deliveries geographically. This reduces the total mileage driven, lowers fuel and labor costs, and improves your overall operational density.

- Real-World Scenario: I’ve seen large distribution clients use this data to reduce their overall fleet mileage by over 18% in the first year alone, turning a historical expense into a true competitive advantage.

Integrating Telemetry Data with ERP/Dispatch Software

The data should not live in a siloed web portal. For scalable operations, the monitoring platform must speak directly to your Enterprise Resource Planning (ERP) or Dispatch software.

This requires the monitoring device and platform to use standard, machine-readable protocols such as API (Application Programming Interface) or MQTT. A monitor that can send its data directly into your existing system is an investment; a monitor that forces an employee to manually transcribe a level reading is an operational burden. Ensure your chosen partner provides a robust, developer-friendly data pipe.

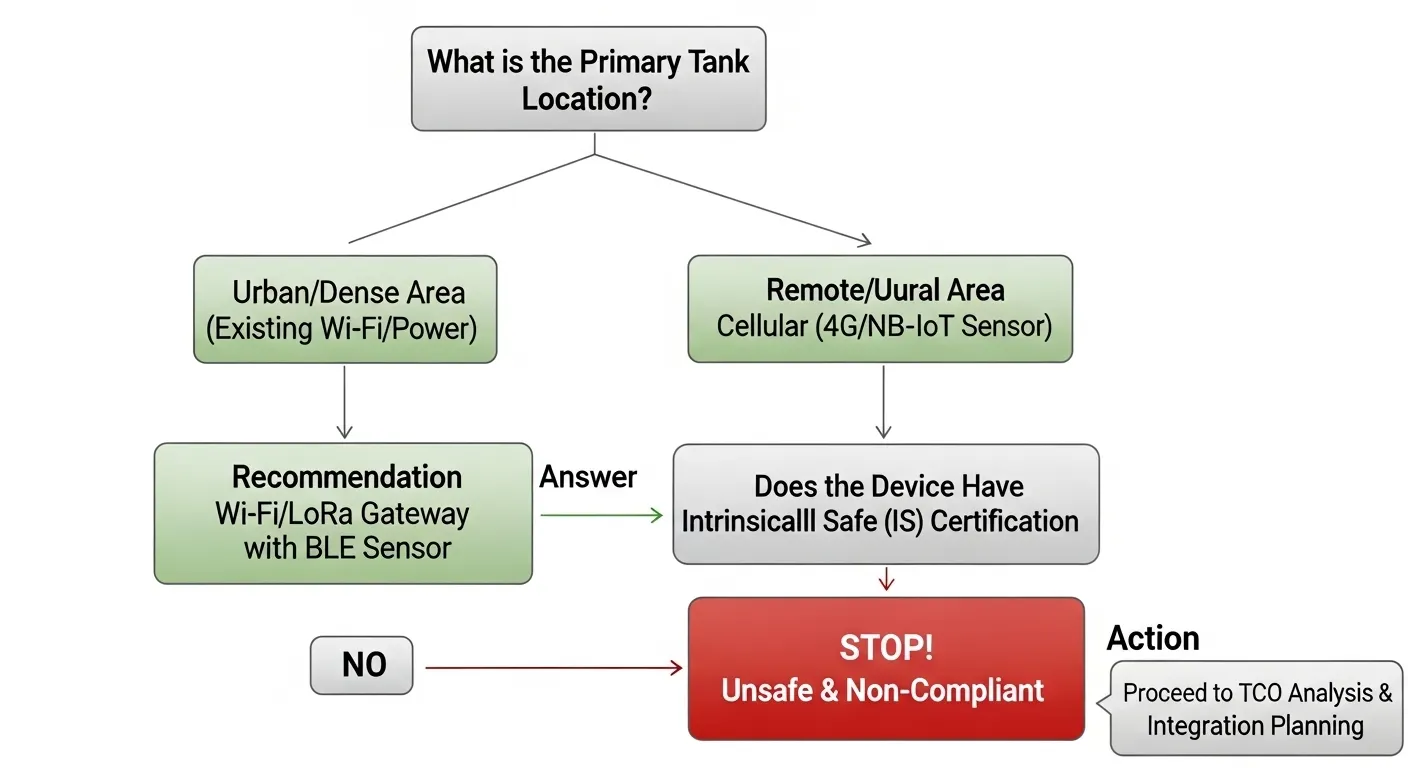

5 Steps to Select Your Ideal Monitoring System

Here is a quick framework, developed from hands-on industrial deployments, to guide your technology selection:

- Validate Safety First: Is the device Intrinsically Safe (IS) certified (ATEX/IECEx) for Zone 1/Division 1 operation? If no, disqualify immediately.

- Determine Measurement Reliability: Does it use an R3D Hall Effect sensor interfacing with the existing mechanical gauge? This offers the best balance of safety, accuracy, and ease of installation.

- Map Your Coverage Needs: Is the tank location remote (no Wi-Fi/power) or local (on a plant-wide Wi-Fi/LoRa network)? Choose Cellular (4G/LoRaWAN) for remote, and consider a Wi-Fi or Bluetooth/Gateway solution only if local power and network coverage are guaranteed and reliable.

- Analyze the Full TCO: Factor in the recurring subscription fee and the predicted battery life. A system that requires a 3-year battery change has a significantly higher TCO than one with a 7-year life.

- Test the Integration: Ensure the provider offers a standard API that can easily pipe the data into your existing ERP or dispatching software. The best hardware is worthless if the data stays locked in a proprietary cloud.

Conclusion: Telemetry is Now a Profit Center

The comparison between Bluetooth, Wi-Fi, and Ultrasonic LP gas tank level gauges isn't about finding a single "best" technology; it’s about aligning the technology with your industrial requirements for safety, precision, and efficiency.

Key Takeaways for Manufacturing and Industrial Clients:

- Hall Effect (R3D) is the most reliable sensor: It uses the existing, robust mechanical float and is far less prone to the temperature and surface interference that plague ultrasonic sensors.

- Cellular/LoRa is the undisputed connectivity choice: It enables the remote, proactive monitoring necessary for delivery optimization and true operational ROI.

- IS Certification is non-negotiable: Safety compliance (ATEX/IECEx) must be your first and foremost filter to avoid catastrophic risk and liability.

- TCO is your metric: Don't look at the purchase price; look at the lifetime cost saved from preventing bad drops and run-outs.

Remote tank telemetry is no longer a luxury—it’s a data-driven profit center. By implementing a certified Hall Effect/Cellular system, you move beyond guesswork and achieve a level of operational efficiency that directly impacts your bottom line.

Ready to move beyond the manual dipstick? Contact us today for a full TCO analysis of an Intrinsically Safe R3D Cellular monitoring deployment for your industrial fleet.

FAQ Section

Ultrasonic sensor accuracy is highly susceptible to temperature fluctuations. Because the speed of sound changes significantly as the temperature of the liquid propane changes, readings can have a $\pm 3\%$ error or more without advanced, power-hungry temperature compensation. This means that a reading taken in freezing winter conditions can be significantly less accurate than one taken indoors or during moderate weather. Hall Effect sensors, which measure a mechanical position, are much less affected.

No, but generally, only the monitors capable of true remote delivery optimization require a subscription. Bluetooth monitors typically do not, but they only work when a mobile device is within close range. Cellular (4G LTE) and LoRaWAN monitors require an ongoing subscription to cover the cost of data transmission from the sensor to the cloud platform, which is the expense that enables your dispatcher to monitor tanks from the office.

The R3D (Remote Ready Dial) gauge is a standard mechanical float gauge designed with an external face that is compatible with electronic Hall Effect readers. A sight glass gauge is a clear tube or window that allows direct visual inspection of the liquid level, often used for small industrial cylinders, but is less common and often less accurate for large bulk tanks and poses an increased leak risk.

Installation of the sensor itself is usually simple—it typically retrofits onto the existing dial gauge under the dome. However, below-ground tanks often require an external antenna or a specialized low-frequency cellular/LoRa connection to transmit the signal reliably through the ground or concrete enclosure. Always check the monitor’s IP rating and antenna specifications for buried or underground service.

The battery lifespan depends entirely on the communication technology. Bluetooth Low Energy (BLE) and LoRaWAN sensors can last anywhere from 5 to 10 years due to their minimal power needs. Wi-Fi sensors, due to the power required to connect to a router, often last only months or, in some cases, less than two years, which significantly increases their maintenance TCO.

For any device placed on a pressure vessel like an LP gas tank, you should look for Ingress Protection (IP) ratings (e.g., IP67 or IP68) to ensure the device is sealed against outdoor elements, weather, and submersion. You should also ensure the device has appropriate FCC/CE certifications for radio frequency transmission.