Akoranga Kēhi:he pēhea te Tiaki a IoT Propane Monitoring i tētahi Kaiwhakanao $40,000 me te ārai i ngā weto hinu kino

Here’s the straight truth: relying on a technician to eyeball a gauge or trusting a supplier’s loose schedule is no longer viable in a modern, lean factory. This case study cuts through the marketing fluff to show the hard ROI me operational security delivered by purpose-built IoT propane monitoring systems. We’re moving beyond simple alerts—we’re talking about integrating a critical resource into your digital factory strategy. Me te 15+ years on the floor, I can tell you that manual tank checks are a massive liability.

Te Raina Raro: IoT propane monitoring prevents outages by providing predictive analytics, which eliminates costly emergency delivery fees and, whakahirahira, eliminates the mandatory system re-initialization and leak test required after a complete run-out. That’s where the true savings lie.

The Ticking Time Bomb: Anatomy of the Propane Outage Problem

In the industrial world, the financial impact of a propane run-out is massively misunderstood. Most people only factor in the cost of an emergency delivery, but that’s peanuts compared to the bigger problems. The costliest part isn't the gas; it’s the legal and operational necessity of bringing the system back online.

The Unseen Cost of "Out-of-Gas"

When your commercial LP gas tank runs completely dry, you can't just hook up a new hose and fire things back up. The system has been compromised, filled with air, and potentially subject to moisture ingress. Local regulations and industry standards—particularly those guided by NFPA 58 (Liquefied Petroleum Gas Code)—mandate a stringent safety protocol.

This protocol typically requires:

- A full system leak check: Every connection, line, and appliance must be inspected for leaks.

- System re-initialization and purging: Air must be bled out of the lines and appliances before propane can safely flow.

- Inspections and Sign-Offs: I te nuinga o te wā, this work must be performed or signed off by a certified technician.

Te hua? Unplanned downtime. If your industrial oven is cold for two days waiting for a certified technician to arrive, perform the checks, and purge the lines, your production schedule is ruined. Add in the Emergency Delivery premium—which I’ve seen run 3 ki 5 times higher than scheduled rates—and you’re looking at a huge, avoidable loss.

The Case Study Subject: "ForgeWorks, Inc."

To illustrate this reality, let’s look at a mid-sized operation we’ll call ForgeWorks, Inc. They’re a specialty metal fabricator using high-BTU propane for industrial furnaces, heat treating, and powering a fleet of material handling equipment.

Context: ForgeWorks was running a lean operation with tight contractual deadlines. Their tank capacity was large, but their usage was highly variable based on production load.

The Problem: Over an 18-month period, ForgeWorks experienced two complete run-outs—both during high-demand production cycles. The second outage, caused by human error (the facilities tech missed the physical gauge during his weekly walk-through), was catastrophic. The documented costs tallied up to over $40,000 in combined expedited delivery fees, mandatory leak check labor, and lost production hours due to the forced 48-hour system downtime.

The Catalyst: The second outage caused a near-miss on a major client contract penalty. They realized the old, manual approach was an unacceptable liability.

The Old Way vs. The New Way

| Operational Function | The Old Way (Manual) | The New Way (IoT Monitoring) |

| Tank Level Check | Visual reading of physical gauge (hē, infrequent labor) | Real-time, minute-by-minute digital sensor reading (remote, tino tika) |

| Delivery Schedule | Reactive or "Will Call" (high risk of run-out/high fees) | Predictive Modeling (automated dispatch based on consumption rate) |

| Labor Cost | Tiketike (Tech must physically check tank daily/weekly) | Near Zero (Alerts are automatic and only sent when necessary) |

| Downtime Risk | Extremely High (Catastrophic run-out risk) | Negligible (Alerts trigger 14 days before potential run-out) |

| Whakaurunga Pūnaha | Zero | Tiketike (API links to SCADA/MES possible) |

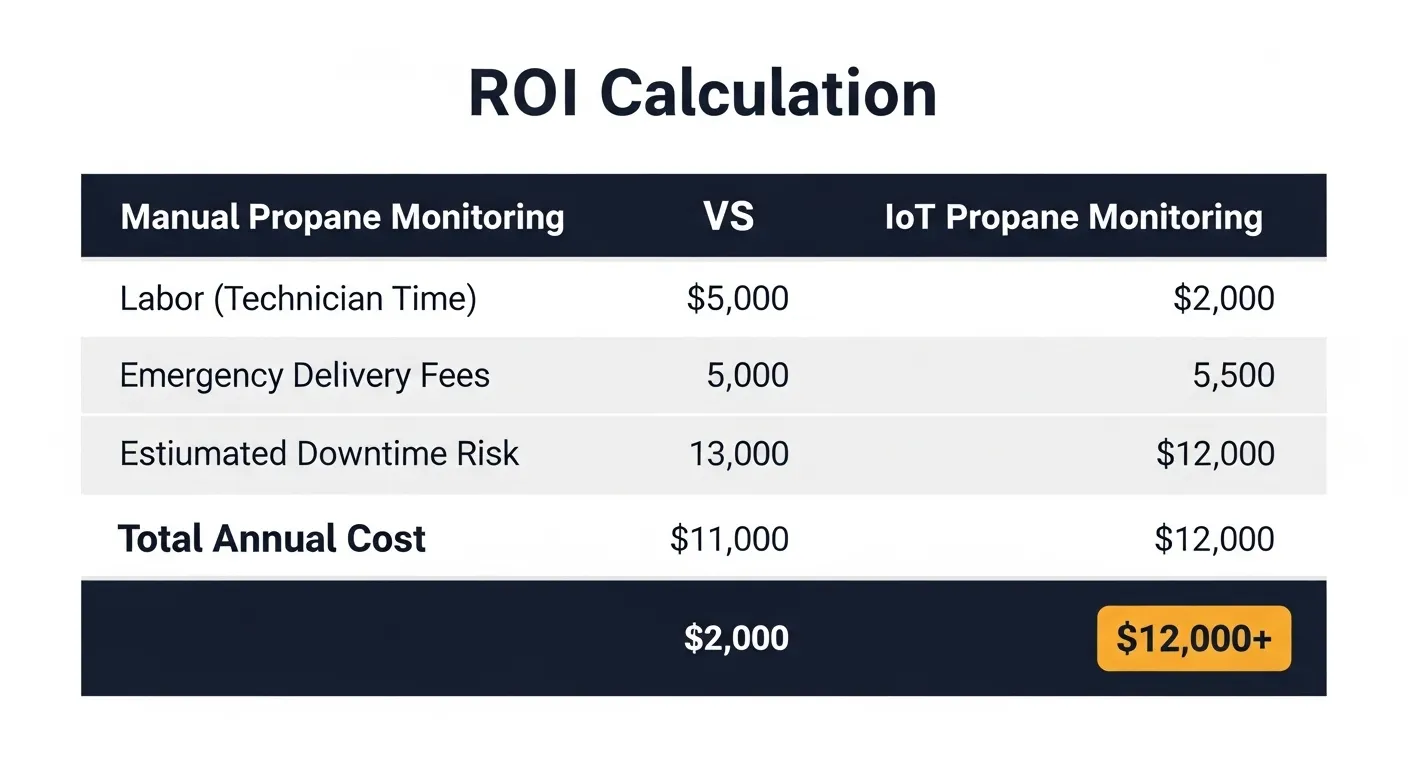

Deep Dive: The Core Value Proposition & ROI Breakdown

The move to IoT propane monitoring transforms a reactive supply chain element into a predictive, margin-enhancing asset. It's not just about knowing your level; it's about optimizing capital and labor.

Eliminating the Unplanned Down-Time Fee

Here’s where we get into the real numbers. The national average cost of unplanned factory downtime can range from $10,000 ki tua $25,000 ia haora, depending on the industry and complexity of the process. Even a small manufacturer's 48-hour delay is a six-figure catastrophe.

Quick Answer: The IoT solution often pays for itself by eliminating just one single emergency delivery and the associated system re-initialization event.

The system gives you the gift of time. Instead of reacting to a crisis, the system provides a 14-day cushion by tracking Gallons Per Day (GPD) consumption and projecting the "days-to-empty." This allows for:

- Scheduled Delivery: Access to the lower, standard rate.

- Full Tank Purge Avoidance: Keeping the level above the critical 5% mark means the system never pulls air, eliminating the mandatory, costly NFPA-mandated restart procedures.

Optimizing the Supply Chain: From Reactive to Predictive

I roto i tōku wheako, the biggest cost lever isn't the price per gallon; it’s the frequency and inefficiency of the truck roll. Why top off a tank at 60% capacity if you can wait until 30% and maximize the volume delivered per trip?

IoT data allows for strategic bulk purchasing and delivery scheduling that matches your actual consumption profile. Koinei te 4-Step Predictive Delivery Model in practice:

- Collect Usage Rate (Gallons/Day): The monitor provides highly accurate daily consumption data, instantly spotting variances.

- Model Seasonal/Load Variance: AI engines learn that your winter heating load is $X$ GPD and your summer process load is $Y$ GPD.

- Set Predictive Threshold: Operations set the minimum safe threshold (E.g., 30% or 14-days-to-empty) to trigger an alert.

- Automated Dispatch/Supplier Notification: The system automatically notifies the supplier's ERP system, allowing them to schedule the delivery on their standard route, often resulting in volume discounts.

The Hidden Benefit: Leak and Theft Detection

The ability to track consumption minute-by-minute offers another critical safety layer. A small leak might drain a few gallons a day, which is imperceptible to a human looking at a gauge. Hoianō, the IoT system will spot a rapid consumption drop that doesn't align with production load—a clear signal of a potential system anomaly, turuturu, or even unauthorized draining (tahae). This allows for proactive inspection and intervention before a small leak becomes a major safety incident.

The Ground-Truth Technology for Industrial Use

When implementing IoT Propane Monitoring, you can't rely on consumer-grade hardware. Industrial environments demand reliability, robust communication, and proper certification.

Sensor Science: Choosing the Right Industrial Gauge Adapter

The vast majority of commercial propane tanks utilize an analog R3D Ready Gauge on the tank head. This is the dial you see. To digitize this reading, a specific industrial sensor is required.

- Hall-Effect Sensors: These are the gold standard for retrofitting R3D-equipped industrial tanks. They are non-invasive, attaching directly to the R3D gauge spindle and translating the mechanical rotation into a digital signal. They are simple to install and highly reliable.

- Ultrasonic/Pressure Sensors: These are sometimes used but can be more complex and expensive for large-scale retrofitting, often requiring direct tank penetration or more sophisticated installation to account for temperature and pressure variations.

Expert Insight: I’ve found that accuracy is a common issue with neglected sensors. Always ensure your supplier provides guidance and support for calibration. For long-term reliability in harsh environments, annual calibration checks are non-negotiable to maintain accuracy.

Network Reliability for Multi-Site Operations

A reliable signal is everything. I nga waahanga ahumahi, the two most common choices are Cellular (NB-IoT/LTE-M) and LoRaWAN.

| Network Type | Tarahi | Toto | Pai mo |

| NB-IoT/Cellular | Ngāwari, plug-and-play installation; long-haul coverage; high data reliability. | Higher subscription and hardware cost; battery life can be impacted by weak signal. | Mamao, scattered tanks; single site with poor local Wi-Fi. |

| LoRaWAN | Extremely long range (miles); low power consumption (Te ora o te pākahiko roa); low cost per device. | Requires installation of a local gateway on-site; more complex setup. | A cluster of tanks in one small area (E.g., a tank farm or multiple small tanks). |

Tino Nui, all equipment deployed in or near a commercial tank, especially in environments where explosive fumes could be present, must be certified—typically meeting ATEX or Class 1, Div 2 standards. If your supplier can’t provide that certification, walk away.

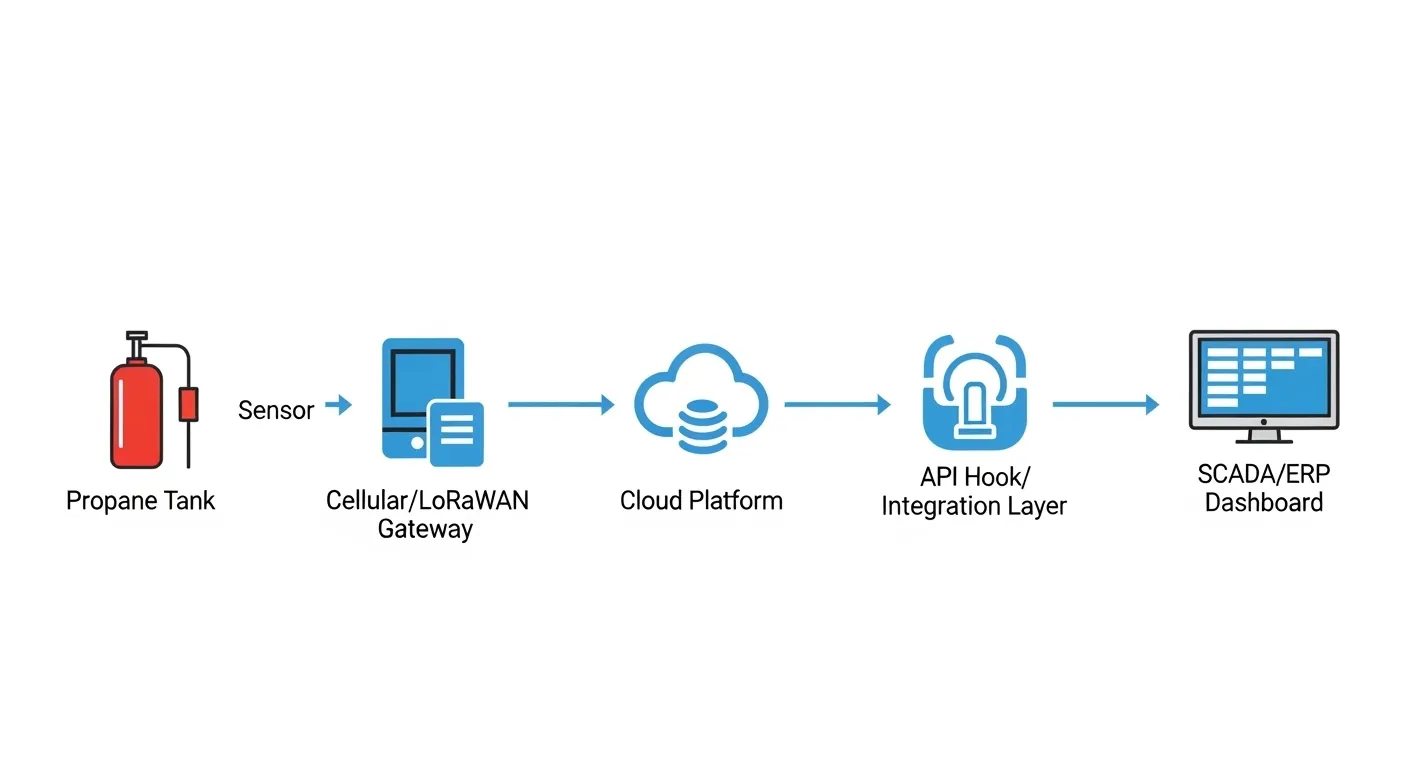

Integrating Propane Data into the Digital Factory

The real power of IoT isn't the phone app; it's the API hook.

- Beyond the App: ForgeWorks realized that having the data in a separate app was still a silo. They needed the tank level to directly inform their production scheduling.

- SCADA/MES Integration: By using the vendor's open API, they pulled the raw tank level and consumption rate into their existing Predictive Maintenance Dashboard. This meant that if the propane tank hit the 30% paepae, it automatically flagged an imminent resource constraint in the same dashboard used by the procurement and production teams.

- The Result: The operations team could forecast production halts two weeks in advance, allowing them to shift schedules or prioritize furnace time, eliminating reactive firefighting.

Implementation: Case Study Results and Lessons Learned

After adopting an industrial-grade IoT monitoring solution, ForgeWorks transformed their propane consumption from an operational risk to a managed asset.

ForgeWorks' First-Year ROI Results

The ROI was verifiable and immediate, paying for the entire system within the first year by avoiding just one major incident.

- Outages: Zero (0) paunga, eliminating all risk of mandatory re-initialization.

- Emergency Fees: Reduced to Zero.

- Labor Savings (Manual Checks): Reduced approximately 10 hours per month of technician time previously spent walking the grounds, logging levels, and calling the supplier.

- Delivery Optimization: Due to accurate predictive analytics, they reduced the number of annual deliveries by 20% (fewer truck rolls, māia ake, high-volume fills).

- Net Tangible Savings (excluding avoided downtime): Neke atu $10,000 in fees and labor.

- Total ROI: Based on their initial setup cost, their first-year verifiable return exceeded 300%.

Competitor Mistakes We Avoided

ForgeWorks followed a careful implementation plan, learning from common pitfalls:

- Avoid Mistake #1: Assuming Plug-and-Play Accuracy. They didn't just trust the initial reading. They performed a manual check and verification against the digital reading right after installation, understanding that ongoing calibration is key.

- Avoid Mistake #2: Relying on Weak Network Coverage. They invested in the robust cellular modem that provided the best data throughput, recognizing that a small saving on network cost isn't worth a data failure.

- Avoid Mistake #3: Failing to Integrate the Data. They didn't leave the tank data in a silo. They ensured the data was fed to the production control team, making the resource level actionable for the entire organization, not just the facility manager.

Future Planning: Expansion to the Forklift Fleet

The success on their primary stationary tanks led ForgeWorks to explore expansion. The same monitoring principle is now being applied to their smaller, high-turnover propane tanks used for their forklift fleet. Managing dozens of cylinders manually is a huge labor sink, but IoT tags on these tanks allow for centralized inventory management, ensuring the stock cage is always full and eliminating the "dead time" when a lift runs out mid-shift. This wider approach to resource management is how you leverage technology across the entire manufacturing floor.

Wāhanga whakamutunga: Propane Monitoring as a Profit Center

IoT propane monitoring is not an expenditure; it is an investment in operational security and efficiency. For a manufacturer, its value is defined by the crises it prevents and the margins it secures.

Ngā Takeaways Matua:

- IoT monitoring is a high-yield insurance policy against the massive cost of unplanned downtime.

- It's a powerful supply chain optimization tool that drastically cuts unnecessary truck rolls and labor costs.

- Te ROI is rapid and verifiable, often paying for itself after the first avoided emergency delivery and re-initialization.

- The true industrial benefit comes from integrating the data into your SCADA/ERP system.

Stop managing a critical resource with a coin toss and start managing it with clear, actionable data. Data-driven operations win every time.

FQ

How long does it take for IoT propane monitoring to pay for itself?

For a mid-sized manufacturer, the system typically achieves a positive ROI within the first 6 ki 12 marama. This rapid return is primarily driven by eliminating just one or two costly emergency delivery fees and, mea nui ake, avoiding the unplanned downtime and mandatory system re-initialization required after a complete out-of-gas event.

Does an IoT monitor eliminate the need for a physical gauge?

Kāore, the IoT monitor works in conjunction with the physical gauge. Most industrial tanks use an analog R3D-ready gauge, and the sensor simply digitizes that reading. The physical gauge serves as a local visual confirmation and a regulatory backup, while the IoT sensor provides the necessary remote data for predictive analytics.

What is an R3D-Ready Gauge, and why is it essential for retrofitting?

An R3D-Ready Gauge is a standard commercial propane tank dial gauge equipped with an accessible magnet or spindle on the back. It is essential because it allows the non-invasive Hall-Effect sensor (the monitor) to attach directly and translate the internal gauge movement into a digital signal without requiring tank penetration or complex wiring.

Can I monitor my propane tank levels on my existing phone/desktop software?

Āe, most industrial-grade IoT solutions provide an open Application Programming Interface (API). This means the raw tank level and consumption data can be easily pulled and integrated into existing business intelligence tools, such as your SCADA, ERP, or Predictive Maintenance dashboard, eliminating data silos.

What is the battery life expectation for an industrial propane monitor?

Industrial propane monitors are designed for long life, often lasting 5 ki 7 years on a single set of batteries. They use low-power networks like LoRaWAN or NB-IoT, and only 'wake up' to transmit data a few times an hour. Temperature extremes can slightly affect battery longevity, but reliability is prioritized for minimal maintenance.

Is LoRaWAN or Cellular (NB-IoT) better for manufacturing facilities?

For a facility with a single, reliable internet connection, pūkoro (NB-IoT/LTE-M) is often preferred for its simplicity—it’s plug-and-play and requires no local gateway. For multi-tank sites spread over a wide area, or very remote locations, LoRaWAN is often more cost-effective as one gateway can handle dozens of sensors over a long distance.