Propane Tank Apps: The Ultimate Guide to Industrial Monitoring & Refill Tracking

A production line stops. Forklifts sit idle. Temporary heaters go cold. The cause? An empty propane tank that someone forgot to check. In a manufacturing environment, a 'simple' propane run-out isn't an inconvenience—it's a multi-thousand-dollar downtime event.

For decades, the "best" method for checking tank levels was whacking the side with a wrench or relying on a maintenance tech's clipboard checklist. This is archaic, inefficient, and costs businesses millions in lost productivity and emergency refill fees.

This is where propane tank apps and smart monitoring systems have fundamentally changed the game. They transform a passive, "dumb" fuel tank into a proactive, data-driven asset.

But let's be clear: this guide isn't for your backyard BBQ grill. This is the industrial-focused breakdown of how this technology works, which type is right for your facility, how to calculate the ROI, and how to integrate it into your existing maintenance and procurement workflows.

What is a Propane Tank App? (And How Does It Actually Work?)

Quick Answer: A propane tank app is a mobile or web application that syncs with a physical sensor (a "tank monitor") attached to your propane tank. This sensor measures the fuel level in real-time and uses a wireless connection (like Cellular or Wi-Fi) to send that data to the app, providing instant level readings, usage history, and low-level alerts directly to your phone or computer.

What I've found is that most people think it's "just an app," but in reality, it's a simple three-part ecosystem:

- The Sensor (The "Eyes"): This is the physical hardware that attaches to your tank and actually measures the propane level.

- The Network (The "Voice"): This is the technology that transmits the data from the sensor. It's almost always Cellular, Wi-Fi, or Bluetooth.

- The App (The "Brain"): This is the software interface—the app on your phone or the dashboard on your PC—where you see the data, track usage over time, and set up critical alerts.

The real "magic" is in the sensor, and as an engineer, this is the part you need to get right. Competitors rarely talk about this, but you're generally buying one of two types.

How the Sensors Work: A Technical Deep-Dive

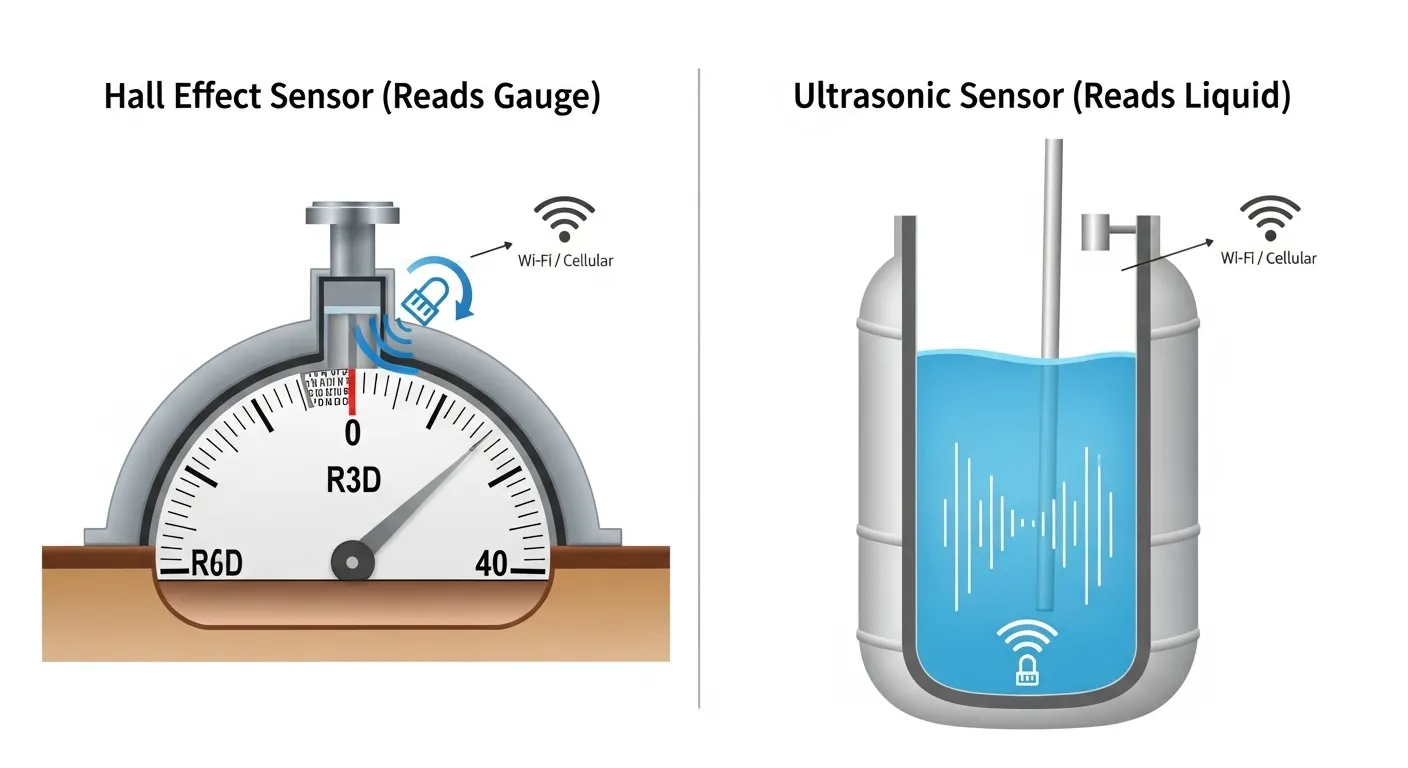

- Hall Effect Sensors (Most Common for R3D Gauges): Most large stationary tanks (500+ gallons) come with a "remote-ready" dial gauge, often a Rochester R3D gauge. A Hall Effect sensor is a small, non-invasive device that simply snaps or screws onto this existing dial. It magnetically reads the position of the needle on the gauge to determine the fuel level.

- Pro: Incredibly easy, tool-free install. You can do it in 5 minutes.

- Con: It's only as accurate as your float gauge, which can be imprecise (often +/- 5-10%). But for a large stationary tank, that's usually good enough.

- Ultrasonic (Sonar) Sensors: These are more advanced. They are typically held by strong magnets to the bottom of the tank. They work like sonar, sending a sound wave up to the surface of the liquid propane and measuring the time it takes for the echo to return. This allows them to precisely calculate the liquid-to-vapor line.

- Pro: Very accurate (often +/- 1-2%). It's a direct measurement of the fuel. This is also the only option for tanks without an R3D gauge, like most forklift cylinders or "hot dog" tanks.

- Con: Can be more expensive and requires a clean, flat surface on the tank bottom.

The Business Case: Calculating the ROI of "No More Run-Outs"

In a residential setting, running out of propane is an annoyance. In a factory, it's a financial liability. The B2C pitch is "peace of mind." The B2B pitch is Return on Investment.

When a critical tank runs dry, the costs cascade immediately:

- Production Downtime: This is the big one. According to industry analysts, unplanned downtime costs manufacturers an estimated $50 billion per year. You need to ask, "What does one hour of our line being down really cost?" It's almost always more than the entire monitoring system.

- Emergency Refill Fees: Your propane supplier hates emergency call-outs. It wrecks their route efficiency. They will charge you a premium for it, sometimes 1.5x to 2x the normal rate, to send a truck out immediately.

- Safety & Compliance: Here's what most don't know: running a tank completely empty can cause it to suck in air and moisture. Per NFPA 58 (the Liquefied Petroleum Gas Code), this can require the tank to be taken out of service for a mandatory pressure test and purge. That's even more downtime and service fees.

- Wasted Labor: Think about the labor cost of paying a maintenance tech to drive around a large campus with a clipboard, manually checking 15 different tanks every day. A monitoring system frees up that skilled tech to do actual preventative maintenance.

The data from a propane tank app flips this entire model. It enables data-driven logistics, allowing you to:

- Optimize Refills: The data allows your supplier to move you from a "guesswork" schedule to a "keep-full" or predictive schedule. They can plan their routes efficiently, delivering when you actually need it. This often results in a better price-per-gallon for you.

- Identify Abnormal Usage: "Why did Tank 3 on the north lot drain 30% faster this month?" A quick look at the app's usage chart can alert you to a potential leak, a malfunctioning heater, or even theft, long before it becomes a major problem.

- Centralize Procurement: If you manage multiple sites, you can track usage across your entire operation from a single dashboard, simplifying your fuel procurement.

The Two Main Models: Supplier-Provided vs. "Bring Your Own Device" (BYOD)

This is the first major decision you'll face, and it's a critical one that competitors fail to explain. You have two main paths to get this technology.

Model 1: The Supplier-Provided Program (e.g., Superior, AmeriGas)

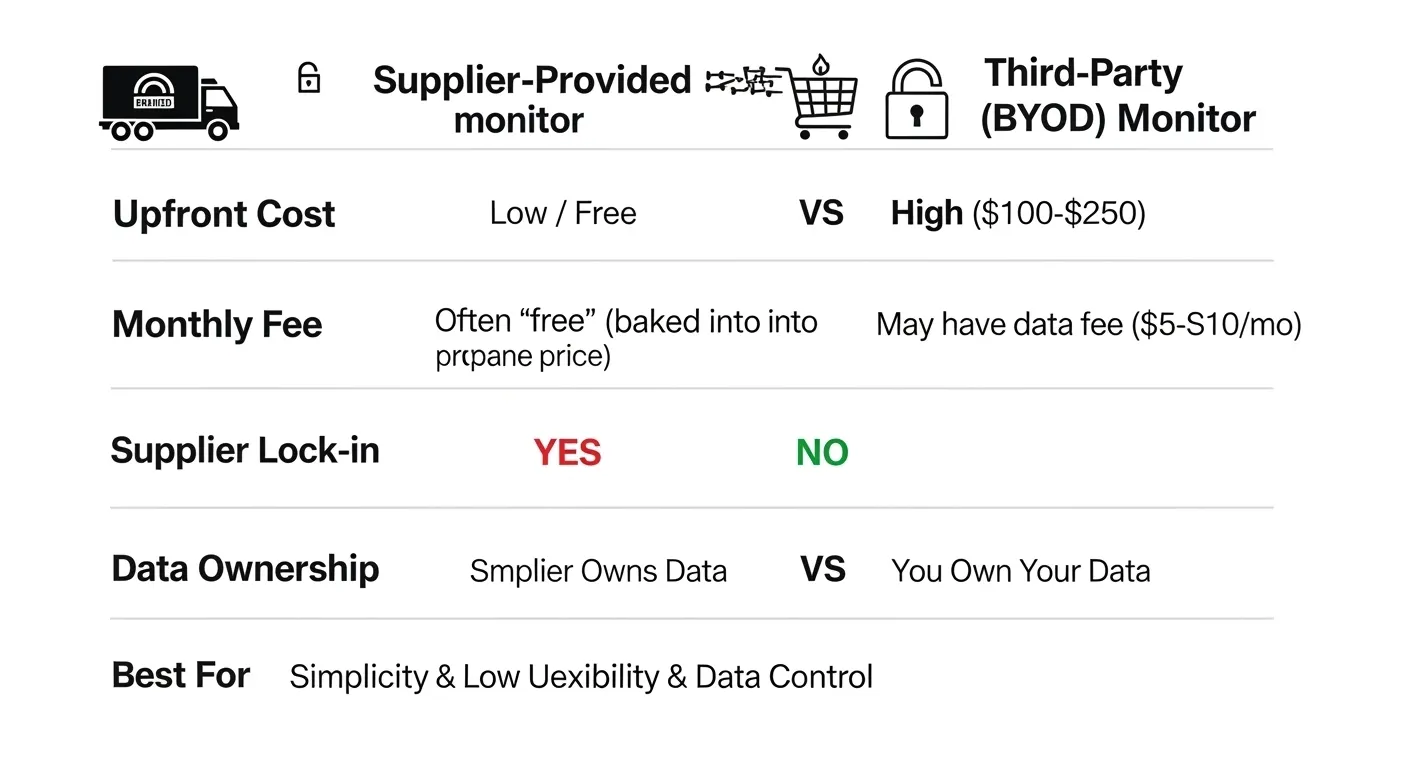

- How it works: Your current propane supplier (like AmeriGas, Superior, etc.) comes to your facility and installs their branded monitor, often for "free" or a low monthly rental fee. They then give you access to their branded app.

- Pros: Low or no upfront hardware cost. It's fully managed and supported by them. The data is often integrated directly with their delivery and billing systems, making it seamless.

- Cons: You are 100% locked into that supplier. The data isn't portable. If you find a better price-per-gallon from a competitor next year and want to switch, you lose the monitor, the app, and all your historical data.

- In my experience: This is a great option for businesses that have a long-term, trusted relationship with one supplier and value simplicity and low cost over data ownership.

Model 2: The Third-Party "BYOD" Monitor (e.g., Generac, Mopeka)

- How it works: You go out and purchase the sensor hardware yourself from a company like Generac (which acquired the popular Tank Utility brand), Mopeka, or ioX-Connect. You own the hardware ($100 - $250) and use the manufacturer's open-platform app.

- Pros: Total flexibility. You own the monitor and, more importantly, you own your data. You can switch propane suppliers every year if you want, and your monitoring system doesn't change. You can even grant temporary access to your new supplier's dashboard. The apps are often more feature-rich.

- Cons: You have a higher upfront hardware cost. For cellular models, you'll also likely have a small monthly or annual data subscription ($5-$10/mo) to pay for the SIM card's data plan.

Not All Connections Are Equal: Bluetooth vs. Wi-Fi vs. Cellular

This is my biggest frustration when I see these systems mis-implemented. A manager buys a monitor only to find it doesn't work because they chose the wrong connection type for their location. This is a huge "Expertise" win for us.

Bluetooth Monitors

- How it works: The sensor only communicates with a phone that is within direct range (typically 30-100 feet).

- Industrial Use Case: Very limited. It's not a remote monitoring solution. It's a "local check" solution. In my opinion, its best use is for forklift cylinders. A driver can use an ultrasonic sensor (like a Mopeka Pro) and their phone to check their tank level before starting a shift, preventing them from running empty in the middle of the warehouse.

Wi-Fi Monitors

- How it works: The sensor connects to your facility's Wi-Fi network to send data to the cloud.

- Industrial Use Case: This is good for tanks located inside a building or just outside a wall where you have a rock-solid Wi-Fi signal.

- The "Gotcha": Here's what most suppliers won't tell you. That Wi-Fi signal from your office AP? It hates trying to get to a large metal tank 150 feet away in the yard. Signal strength will be weak, connections will drop, and you'll get false "sensor offline" alerts. Only use this if you are positive your Wi-Fi coverage is robust at the tank's exact location.

Cellular Monitors (The Industrial Standard)

- How it works: The sensor has its own built-in cellular modem and SIM card. It uses the same networks as your cell phone (e.g., AT&T, Verizon) to send data from virtually anywhere.

- Industrial Use Case: This is the gold standard for 90% of industrial applications. It's perfect for remote tanks on a large campus, backup generators at the edge of your property, agricultural operations, or temporary construction site heaters.

- Expert Insight: This is the model that requires a small data subscription. When you're sourcing them, ask the vendor specifically about the technology they use. Modern monitors use LTE-M or NB-IoT, which are "low-power, wide-area" network technologies designed for this exact type of low-data, long-battery-life IoT device.

How to Implement a Smart Tank Monitoring System (Step-by-Step)

Ready to make the switch? Here's the practical, step-by-step implementation plan I'd use.

Step 1: Audit Your Assets

Don't just buy a monitor. First, walk your site and map your propane-powered assets. Ask:

- Where is every tank?

- What size is it?

- What does it power (e.g., critical process heater, backup generator, forklift fleet)?

- What's the real cost of a run-out for this specific tank? (This helps you prioritize).

- What kind of gauge does it have? Take a picture. Does it say "R3D" on the dial?

Step 2: Choose Your Model (Supplier vs. BYOD)

Based on that audit, make the call. Call your current propane supplier first. Ask them, "Do you offer a smart tank monitoring program for commercial accounts?" Get the details: the cost, the hardware, the app. Then, spend 20 minutes researching third-party options like Generac or Mopeka to compare.

Step 3: Choose Your Connectivity

Look at your map from Step 1. That tank by the shipping office with full Wi-Fi? A Wi-Fi model is fine. The backup generator on the back fence? That must be a cellular model. The forklifts? That's a Bluetooth/Ultrasonic combo.

Step 4: Installation & Setup

In most cases, this is a 5-minute, tool-free job. I've done it myself many times. The Hall Effect sensors literally snap onto the gauge. The ultrasonic ones just stick to the bottom with magnets. It's truly simple. Once it's on, you download the app, create an account, and scan a QR code on the device to sync it.

Step 5: Configure Your Alerts (The Most Important Step)

A monitor with no alerts is just a digital gauge. The real power is in the automation. Don't just set one alert. Set up a "notification cascade" based on propane fill levels:

- "Heads-Up" Alert at 40%: Send an email to the procurement admin. This is the trigger to schedule a routine, non-emergency refill.

- "Critical" Alert at 20%: Send a high-priority push notification and a text message to the Plant Manager and the Maintenance Lead. This is the "act now" alert to prevent a shutdown.

Conclusion: Stop Guessing, Start Measuring

For decades, fuel management has been a reactive, inefficient guessing game. That era is over. A propane tank app isn't just a gadget; it's an essential industrial IoT tool that prevents costly downtime, optimizes supplier logistics, and gives you precise control over a critical commodity.

Here are the key takeaways:

- It's an ROI play: A smart monitor's cost is negligible compared to the cost of a single production-halting downtime event.

- It's a system: You're choosing a sensor (Hall Effect vs. Ultrasonic), a connection (Cellular is the standard), and a business model (Supplier-Locked vs. BYOD).

- Data is power: The data you get allows for predictive refills, which saves you money and eliminates the "emergency call" premium.

- Cellular is king: For almost any industrial or remote tank, a cellular (LTE-M) monitor is the most reliable, "set it and forget it" solution.

Stop treating your facility's fuel supply as a guessing game. Take 15 minutes today to audit your propane tanks and call your supplier. Ask them one simple question: "What smart monitoring program do you offer for your commercial clients?" The answer could save you thousands.

Frequently Asked Questions (FAQ)

Can I put a smart monitor on a rented propane tank?

Yes, but you must check with your propane supplier first. If you own your tank, you can install any monitor you want. If you lease or rent the tank (which is common), your supplier may require you to use their specific monitoring system or may have rules against adding third-party devices. Always call them first.

What is the best app for monitoring propane tanks?

The "best" app depends on your hardware. If you use your supplier's program (like Superior's mySUPERIOR app), that's the one you must use. For third-party monitors, Generac's Mobile Link (which absorbed the popular Tank Utility platform) and Mopeka's TankCheck are widely considered the most popular and robust platforms.

How accurate are propane tank monitors?

It varies by type. Hall Effect monitors that read your existing float gauge are only as accurate as that gauge, which is typically +/- 5-10%. This is fine for large tanks. Ultrasonic sensors, which measure the liquid level directly, are far more accurate, often within +/- 1-2%.

How much do propane tank monitors cost?

Hardware for third-party monitors typically costs between $100 and $250 per device. Cellular models often have a subscription fee of $5-$15 per month or an annual fee ($50-$100) to cover the cellular data plan. Supplier-provided monitors are often "free" or a low monthly rental, but they lock you into their propane service.

Do propane tank monitors work on forklift cylinders?

Yes! This is a perfect use case for ultrasonic (bottom-mount) sensors, as forklift tanks don't have R3D gauges. A Bluetooth-enabled ultrasonic sensor (like the Mopeka Pro) allows drivers to check their tank level on their phone before starting a shift, preventing them from running empty mid-operation.