Propane Tank Not Level? Causes, Fixes, and When to Call a Technician

You glance out the window and something looks... off. Your large propane tank is tilting, maybe sinking into the ground on one side. It’s not just an eyesore; it's a gut-feeling that tells you something isn't right.

Let's get straight to it. The short answer: No, it is not okay for your propane tank to be unlevel. A level tank is absolutely critical for safety, proper function, and accurate fuel readings. An unlevel tank isn't just a minor issue—it's a sign of a problem that could lead to you running out of fuel unexpectedly, damaging your appliances, or creating a serious safety hazard.

In this article, I'm going to draw on my 15+ years of experience with industrial and residential propane systems to explain exactly why this is happening, the real dangers (beyond what most suppliers list), and a clear, step-by-step plan to get it fixed.

Why a Level Propane Tank Isn't Just "Nice to Have"—It's Critical

Most people think the concrete blocks or pad are just to keep the tank from getting muddy. The truth is, the entire system—from the gauge to the safety valves—is engineered to operate under one assumption: that the tank is perfectly level. When it's not, things start to go wrong.

The #1 Problem: Inaccurate Fuel Gauge Readings

Here's the biggest issue I see in the field. That little round gauge on top of your tank? It's not a high-tech sensor, and knowing how to check your propane tank level properly is key. It's a simple, reliable piece of mechanics: a float on a hinged arm, just like the one in your toilet tank.

That entire mechanism is calibrated to read "percent full" only when the tank is level.

- If your tank tilts away from the gauge: The float will sit artificially high. In my experience, a tank tilted just 5 degrees can throw the gauge reading off by 10% or more. Your gauge might read "40%" when you're really at 25%, putting you in serious danger of a surprise run-out in the middle of a winter storm.

- If your tank tilts towards the gauge: The float hangs lower than it should. Your gauge might read "15%" when you still have 30% left, causing you to order an expensive, off-route fill you don't actually need.

You're paying for propane you can't accurately measure. That's a real-world cost.

The Serious Safety Risk: Liquid Propane in Your Vapor Line

This is the part that's truly dangerous. Your appliances (furnace, water heater, stove) are designed to run on propane vapor (gas), not liquid.

Propane tanks are designed to have the liquid sit at the bottom, with a space at the top where the liquid turns into vapor. The service valve, where the gas line connects, is designed to pull only from this vapor space.

When a tank is severely tilted, the liquid propane can slosh and get high enough to be drawn into the vapor service valve.

This is a critical failure. Liquid propane in a line designed for vapor can slug and damage your appliance regulators, clog burner orifices, and, in a worst-case scenario, create a significant fire hazard as the liquid rapidly expands back into gas where it shouldn't.

The Long-Term Damage: Stress on the Foundation and Fittings

Let's not forget about the simple physics of weight. A 500-gallon tank full of propane can weigh over 4,000 pounds. All of that weight needs to rest evenly on its foundation.

When the tank is unlevel, that weight is concentrated on one point. This puts immense, uneven stress on the tank's "feet" (chines), the blocks or pad underneath, and, most importantly, the rigid and copper lines (called "pigtails") connected to it. This can:

- Crack the concrete blocks or pad, making the problem worse.

- Cause the tank's base to dig into the ground, accelerating rust.

- Put a constant strain on the valve fittings, which can lead to fatigue and potential leaks over time.

Common Causes: Why Is My Propane Tank Sinking or Tilting?

I've been called out to fix dozens of these. The tank didn't just decide to move on its own. The problem is almost always with the foundation, and it typically falls into one of these four categories.

Cause 1: Improper Installation (The Most Common Culprit)

Frankly, this is the one I see most often, especially on older homes. The installer rushed the job. They didn't create a proper, compacted base, used cheap or cracked blocks, or just didn't bother to use a level when they set the tank. The NFPA 58 code (the "bible" of the propane industry) clearly states that tanks must be installed on a firm, non-combustible foundation to prevent settling. A few pieces of loose brick on soft dirt doesn't cut it.

Cause 2: Ground Settling and Soil Type

If your tank is in an area with soft, loamy, or clay-heavy soil, it's prone to settling. The sheer weight of the tank—all 4,000+ pounds of it—slowly compacts the soil underneath. After a few years, especially after a very wet season, one side has simply sunk further than the other.

Cause 3: Seasonal Problems (Frost Heave and Thaw)

For those of us in colder climates, "frost heave" is a powerful force. The moisture in the ground freezes, expands, and can literally push the concrete blocks or pad up. The problem is, when it thaws in the spring, it never settles back down in the exact same spot. After a few winters of this freeze/thaw cycle, the tank is left sitting on a crooked, unstable base.

Cause 4: Erosion and Water Runoff

Take a look at your tank's surroundings. Is it at the bottom of a slope? Is a new gutter downspout from your roof pointed right at the tank's base? I once saw a tank tilting because the homeowner's new sprinkler system for a flower bed was washing away the gravel base, one watering at a time. This constant water flow will wash away the supporting soil or gravel, causing one side to sink into the new-found void.

How to Fix an Unlevel Propane Tank: A Triage Guide

Okay, you've confirmed your tank is unlevel. Now what? Your next move is critical, and for the sake of your safety, it's not a DIY project.

First: Who is Responsible? You or Your Propane Supplier?

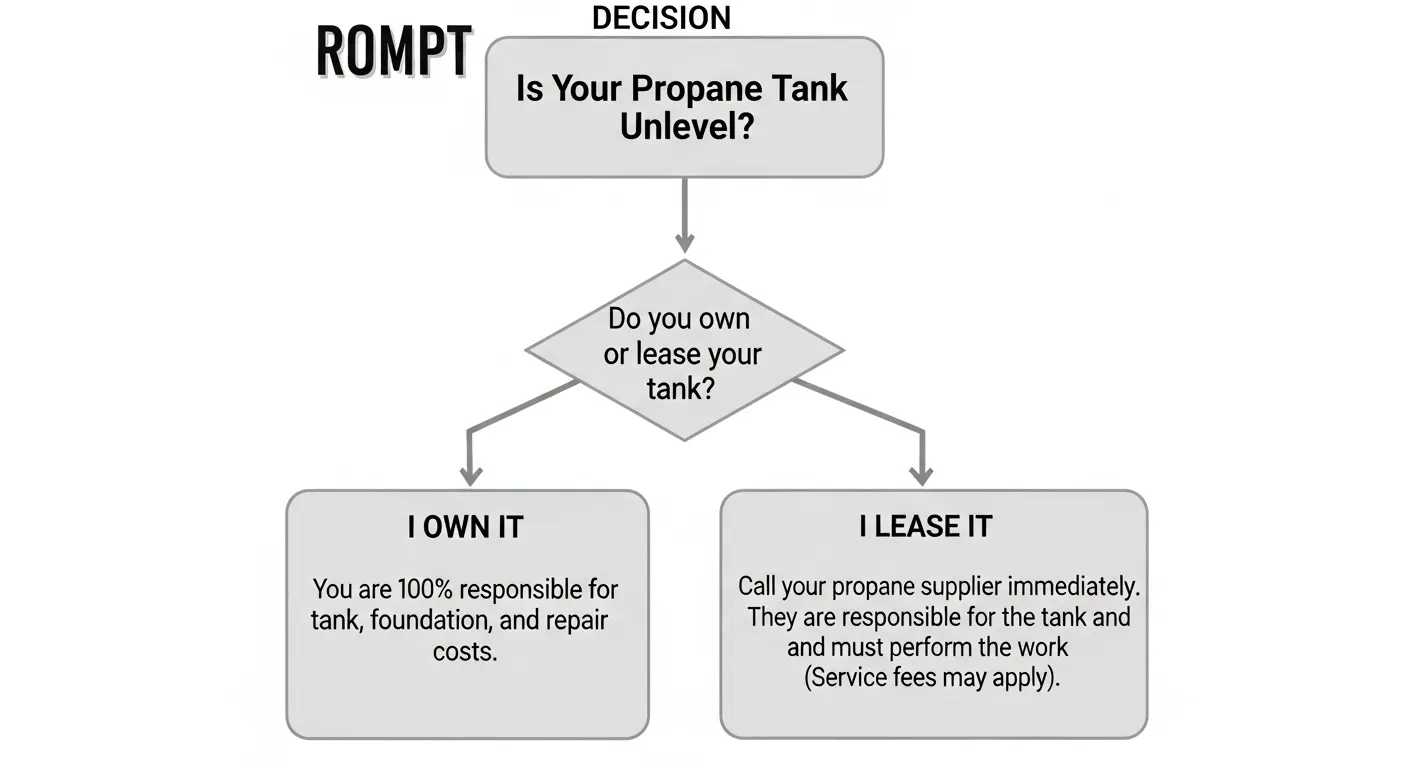

This is the key question that most suppliers' websites avoid. The answer, as you'd expect, comes down to your agreement.

- If you own your tank: The answer is simple. You are 100% responsible for the tank, the foundation, and the cost of the fix.

- If you lease (rent) your tank: This is the most common scenario. In most residential lease agreements, your supplier is responsible for the tank itself and its service connections. However, you are typically responsible for the ground it sits on and ensuring "clear and level access."

The Bottom Line: In most cases, the supplier will be the one to do the work (they have to, for safety), but they may charge you a service fee if the cause was due to your property (like the erosion from that downspout or a collapsing retaining wall).

Your first call should always be to your propane supplier. Tell them, "I believe my tank is unlevel and creating a safety issue." This will get a technician out to assess it.

DIY vs. Pro: What You Can (and Absolutely Cannot) Do

- DIY (Small Grill Tanks): Is your 20-lb tank on your BBQ grill crooked? Go ahead and shim the grill's wheels. That's not a safety issue.

- DO NOT DIY (Large Tanks): Let me be crystal clear: You must never attempt to lift, shim, or move a large (100+ gallon) stationary propane tank yourself.

This isn't a matter of pride; it's a matter of life and death. That tank is impossibly heavy. It's connected to high-pressure gas lines. You could easily rupture a copper line, snap a valve, or, worst of all, have the tank roll off its blocks and onto you. This is a job for trained technicians with the right equipment, period.

The Professional Re-Leveling Process (What to Expect)

When you call your supplier, you build trust by knowing what the process should look like. A professional crew will:

- Safety Check: First, they'll inspect the entire tank, the connections, and the gauge to assess the severity of the problem.

- Pumping Down (If Needed): This is the biggest factor in the cost. If the tank is full or the tilt is severe, they must pump the liquid propane out into a temporary holding tank on their truck. They cannot safely lift a full tank.

- Lifting & Resetting: Once the tank is empty (or light enough), they'll use a crane from their service truck or specialized hydraulic jacks to lift the tank clear of its foundation.

- Rebuilding the Base: This is the real fix. They won't just toss a new block under it. They will excavate the old, failed base, bring in new crushed stone, use a hand-tamper to compact it, and then set new, level concrete blocks or pour a small pad.

- Resetting and Re-connecting: They will carefully lower the tank back onto its new, perfectly level base, re-connect all the lines, and perform a comprehensive leak test on all fittings to ensure the system is 100% secure.

What About the Cost?

Here's the transparent answer you're looking for.

- Simple fix (minor shim): If the tank is nearly empty and just needs a minor adjustment, you might only be looking at a standard service call fee ($75 - $150).

- Complex fix (requires pump-out and new base): This is a major job involving multiple technicians and specialized equipment. If they have to pump out 400 gallons of propane, rebuild the base, and set the tank back, you should expect this to cost anywhere from $400 to $1,000+ depending on the tank size and the labor involved.

Conclusion: Don't Wait for a Small Tilt to Become a Big Problem

An unlevel propane tank is not a cosmetic issue; it's a safety and performance problem ticking away in your yard. What starts as a small tilt can lead to a surprise no-fuel emergency, damaged appliances, or a failed tank foundation.

Here's what to remember:

- An unlevel tank causes inaccurate gauge readings, leaving you guessing about your fuel level.

- It can lead to dangerous liquid propane being pulled into your vapor lines, damaging your appliances.

- The cause is almost always a failed foundation from a bad install, ground settling, or water erosion.

- Never try to level, lift, or shim a large propane tank yourself.

If your tank is tilting, your first and only call should be to your propane supplier. Getting it fixed is a key part of regular propane tank safety and maintenance. Get a trained technician out to assess it before your next fill. It's a simple call that protects your home, your appliances, and your family's safety.

FAQ: Quick Answers to Your Propane Tank Level Questions

It must be perfectly level. While codes (NFPA 58) focus on the stability of the base, all gauges and valves are designed to operate with the tank at 0 degrees. There is no "acceptable" amount of tilt for a stationary tank.

A minor amount of uniform settling (a few millimeters) over 10-15 years might occur, but any visible tilt, sinking on one side, or a gap under the blocks is not normal and needs to be addressed by a professional.

Yes, indirectly. The uneven stress puts a constant strain on the rigid gas lines, valves, and fittings. Over time, this stress can fatigue the metal or seals and cause a dangerous leak at the connection points.

A large (100+ gallon) tank must sit on a stable, non-combustible base. The best option is a single poured concrete pad. The most common (and acceptable) is two solid, level concrete blocks or "tank pads" set in a compacted gravel base. It should never sit directly on the ground or on wooden blocks, which can rot and trap moisture.

A responsible driver should not. If a driver notes that a tank is dangerously unlevel, it's considered a "red tag" condition. They should refuse to fill it until a service technician has corrected the problem. Filling a tilting tank is a liability and a safety risk they should not be willing to take.