Essential Guide to Sensor Flow Meter Technology and Installation

Sensor flow meter technology gives you the tools to measure flow with high precision. You can rely on these devices for accurate flow measurement in water, chemicals, or gases. The market for sensor flow meter solutions reached about USD 4.29 billion in 2023, with ultrasonic technology leading in 2024. The table below shows important global trends:

| Aspect | Details |

|---|---|

| Market Value (2023) | Approx. USD 4.29 billion |

| Largest Technology Segment (2024) | Ultrasonic technology |

| Industrial End-User Revenue Share (2024) | 61.4% |

| Regional Leader (2024) | North America (34.5%) |

You benefit from advanced flow measurement technology, such as digital signal processing for better accuracy and self-diagnostics for less downtime. For example, a chemical plant used ultrasonic meters and saw fewer errors. Flow measurement technology helps you achieve reliable and efficient processes.

Sensor Flow Meter Types and Working Principles

Electromagnetic Sensor Flow Meter

You can use electromagnetic flow meters for accurate flow measurement in many industries. These flowmeters work by placing coils around the pipe and electrodes across it. When a conductive fluid moves through the magnetic field, it creates a voltage. This voltage is directly related to the flow velocity. You benefit from this technology because it does not have moving parts, so it lasts longer and needs less maintenance. Electromagnetic flow meters achieve high accuracy, often around ±0.2% for accumulative flow measurement. You can use them for water, wastewater, slurries, and even fluids with suspended solids. These meters do not react to changes in fluid density, temperature, or pressure. You should remember that electromagnetic flow meters only work with conductive fluids.

Tip: Always check the fluid’s conductivity before choosing this flowmeter for your application.

Ultrasonic Sensor Flow Meter

You can rely on ultrasonic flowmeters for non-intrusive flow measurement. These devices use ultrasonic pulses that travel through the pipe wall and the fluid. The meter measures the time it takes for the sound waves to move between sensors. This time difference helps you calculate the flow rate. Portable ultrasonic flowmeter models clamp onto the outside of the pipe, so you do not need to cut or stop the flow. You avoid contamination and reduce installation time. These flowmeters work well with many pipe materials and sizes. You can use a portable ultrasonic flowmeter for water, chemicals, and even food processing. The accuracy can reach ±1% or better. You also get diagnostic features that help you plan maintenance.

| Advantages of Portable Ultrasonic Flowmeter | Limitations |

|---|---|

| No contact with fluid | Sensitive to pipe material |

| No moving parts | Needs proper alignment |

| Easy installation | Accuracy affected by bubbles or solids |

Turbine Sensor Flow Meter

You can use turbine flowmeters for clean liquids and gases. The flow moves a rotor inside the meter. The speed of the rotor matches the flow velocity. You get a direct reading of flow measurement. Turbine flowmeters offer a wide flow range and a compact design. You should install them with straight pipe sections before and after the meter. This setup helps you avoid turbulence and get accurate measurements. You need to clean the rotor and check for debris often. Portable ultrasonic flowmeter options may suit you better if you want less maintenance. Turbine flowmeters can wear out over time, especially if the fluid has particles.

Note: Always follow the manufacturer’s guidelines for installation and maintenance to keep your flowmeter accurate.

Thermal Mass Sensor Flow Meter

You can use a thermal mass flowmeter when you need to measure the mass flow rate of gases or liquids. This type of flowmeter works by using two temperature sensors. One sensor heats up, and the other stays at the fluid’s temperature. As the fluid flows over the heated sensor, it absorbs heat. The difference in temperature between the two sensors helps you calculate the flow rate. You get real-time readings from the display, and the electronics inside process the signals quickly.

Thermal mass flowmeters are popular in many industries. You will find them in oil and gas plants, chemical factories, and food processing lines. They also help in pharmaceutical manufacturing and environmental monitoring. Wastewater treatment plants use them to track flow rates. These meters offer high precision, usually within ±0.5–1.0% of the maximum flow. You do not need extra temperature or pressure compensation, which makes your job easier. You should know that thermal mass flowmeters are sensitive to changes in ambient temperature and contamination. Regular cleaning and calibration help keep your measurements accurate.

Tip: If you need to measure different gases, you can adjust the flowmeter using correction factors. This helps you get reliable flow measurement for each type of gas.

Differential Pressure Sensor Flow Meter

You can rely on a differential pressure flowmeter for many industrial applications. This flowmeter uses Bernoulli’s principle. It measures the pressure drop caused by fluid speeding up through a restriction, such as an orifice plate or venturi tube. The flowmeter has sensors that detect the pressure before and after the restriction. The electronics convert this pressure difference into a flow rate.

Differential pressure flowmeters work well in oil and gas, mining, power generation, and chemical processing. You can use them for liquids, gases, and steam. These meters have a compact design and need little straight pipe, so you save space and money. The V-Cone model is known for its long lifespan and reliability, even with tough fluids like crude oil or wet gas. You get accuracy up to ±0.5% of the flow rate. Since there are no moving parts, maintenance stays low. You should position the transmitter correctly to protect it and ensure accurate flow measurement.

- Main features of differential pressure flowmeters:

- Measure flow by detecting pressure drop across a restriction

- Use sensors and transmitters for accurate readings

- Suitable for many fluids and tough environments

- Low maintenance and long service life

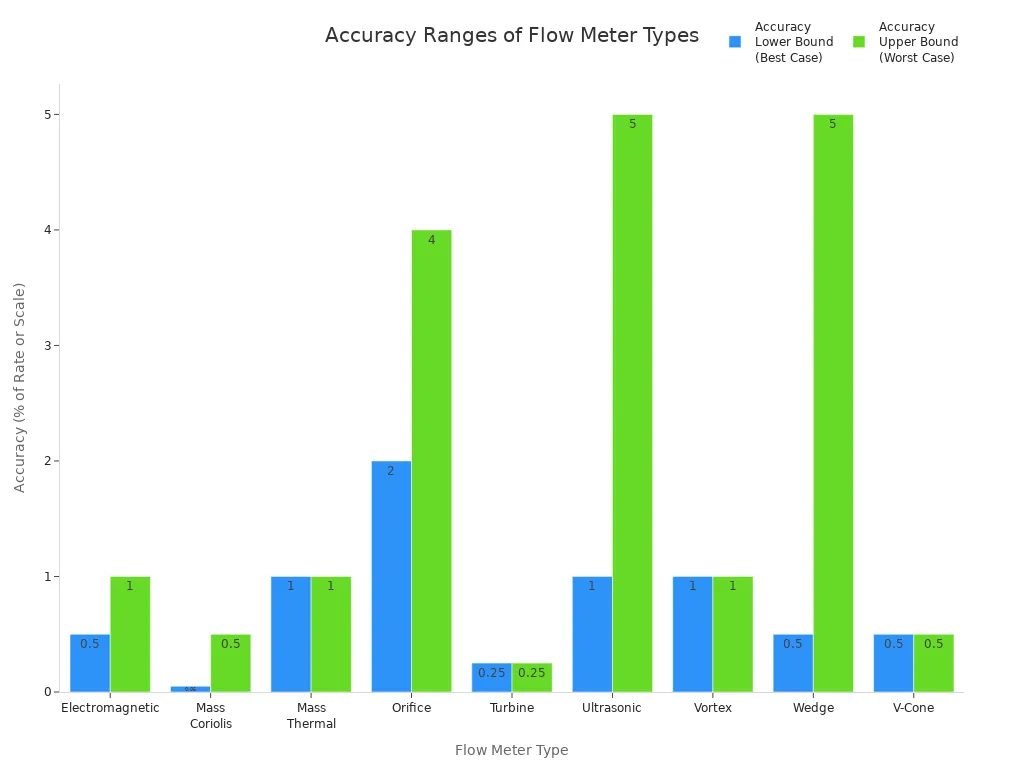

Application Suitability and Key Differences

You need to choose the right sensor flow meter for your process. Each flowmeter type has strengths and weaknesses. The table below helps you compare accuracy, cost, and best uses:

| Flow Meter Type | Accuracy Range | Relative Cost | Suitable Applications | Unsuitable Applications | Notes on Operation and Suitability |

|---|---|---|---|---|---|

| Electromagnetic | ±0.5% to 1% of rate | High | Conductive liquids, slurries, clean or dirty fluids | Hydrocarbons, low conductivity fluids, gas flow | No moving parts, no pressure drop, wide pipe size range |

| Mass - Coriolis | ±0.05% to 0.5% of rate | High | Clean/dirty liquids, gases, slurries, fluctuating temp/pressure | N/A | No moving parts, low pressure drop, limited pipe size range |

| Mass - Thermal | ±1% of rate | High | Clean/dirty liquids, some slurries | N/A | No moving parts, low pressure drop, limited pipe size range |

| Orifice | ±2% to 4% of scale | Low | Clean/dirty liquids, some slurries | N/A | Medium pressure drop, sensitive to viscosity, wide pipe size range |

| Turbine | ±0.25% of rate | Medium | Clean viscous liquids and gases, turbulent flow | Corrosive fluids, liquids with solids | Moving parts (rotor), higher pressure drop, wide pipe size range |

| Ultrasonic | ±1% to 5% of full scale | Medium | Clean (transit-time) and dirty (Doppler) liquids | Gases | Non-invasive, low pressure drop, wide pipe size range |

| Vortex | ±1% of rate | Medium | Clean and dirty liquids and gases, steam, turbulent flow | High viscosity fluids | No moving parts, medium pressure drop |

| Wedge | ±0.5% to 5% of scale | Medium | Slurries, viscous liquids | N/A | Low to medium pressure drop, wide pipe size range |

| V-Cone | ±0.5% | Medium | Pharmaceuticals, oil, gas, chemical, food, steam, etc. | N/A | No moving parts, low maintenance, suitable for retrofit |

You should use electromagnetic flowmeters for conductive liquids. Turbine flowmeters work best for clean fluids. Ultrasonic flowmeters suit non-intrusive flow measurement. Differential pressure flowmeters offer high accuracy for many fluids. Thermal mass flowmeters are ideal for gases and some liquids. Coriolis flow meters provide top precision for mass flow measurement. Always match the flowmeter to your fluid type, process needs, and budget. This helps you get the most reliable measurements and efficient flow measurement.

Selecting the Right Sensor Flow Meter for Your Application

Choosing the right flowmeter for your process helps you get accurate flow measurement and reliable results. You need to look at several important factors before you decide. These include the type of fluid, the flow range, the accuracy you need, and the environment where you will install the meter. Each factor affects how well your sensor flow meter will work in your application.

Fluid Properties and Compatibility

You must match the flowmeter to the properties of your fluid. The type of fluid—whether it is a gas, liquid, or vapor—changes which flowmeter works best. Some fluids have high viscosity, while others may be corrosive or contain particles. These properties can affect both the accuracy and the lifespan of your flowmeter.

| Fluid Property | Effect on Flow Meter Compatibility and Performance | Meter Types Affected / Recommended Meter Types |

|---|---|---|

| Viscosity | High viscosity can increase pressure drop and reduce accuracy. Turbine and differential pressure meters are sensitive to this. | Differential Pressure, Turbine (sensitive); Electromagnetic, Ultrasonic (less sensitive) |

| Temperature | Changes in temperature can alter fluid density and viscosity. Some meters need compensation for this. | Thermal Mass (insensitive), Electromagnetic, Ultrasonic |

| Chemical Composition | Corrosive or abrasive fluids need meters made from resistant materials. Meters with no moving parts last longer in these cases. | Electromagnetic, Ultrasonic (no moving parts, corrosion resistant) |

If you use a turbine flowmeter with thick or dirty fluids, you may see early wear and poor readings. Electromagnetic and ultrasonic flowmeters work well with fluids that have particles or are corrosive because they have no moving parts. Always check that the flowmeter’s materials can handle your fluid’s chemical makeup. This step helps you avoid damage and keeps your flow measurement accurate.

Tip: If your process uses fluids with changing temperatures or high solids, pick a flowmeter that is less sensitive to these changes, like an electromagnetic or ultrasonic type.

Flow Range and Accuracy Considerations

You need to know the flow range and the level of accuracy your process requires. Each flowmeter has a specific operating range. If your flow measurement falls outside this range, you may get incorrect results. High-precision applications, such as those in the food or pharmaceutical industries, need meters with tight accuracy limits.

| Flow Meter Type | Accuracy Specification | Recommended Consideration for High-Precision Applications |

|---|---|---|

| Coriolis Flow Meters | ±0.1% or better | Use for mass flow measurement in industries needing high precision |

| Electromagnetic Flow Meters | ±0.2% or better | Good for conductive fluids; match flow range to process needs |

| Turbine Flow Meters | ±0.5% or better | Needs clean, low-viscosity fluids and regular calibration |

You should always select a flowmeter with an operating range that matches your expected flow rates. If you expect large changes in flow, look for a meter with a wide turndown ratio. This feature lets the meter handle both low and high flows without losing accuracy. Proper installation, such as using full pipes and correct orientation, also helps you get the best flow measurement.

- When choosing a flowmeter, consider:

- The minimum and maximum flow rates in your process

- The accuracy needed for safe and efficient operation

- The repeatability of the meter’s readings

- The need for regular calibration and maintenance

Note: Regular calibration and maintenance keep your flowmeter accurate over time.

Installation Environment Factors

The environment where you install your flowmeter can affect its performance and lifespan. You need to think about temperature, humidity, vibration, and the installation location. Some meters work better indoors, while others can handle outdoor or hazardous areas.

| Environmental Factor | Impact on Flow Meter Performance and Installation | Recommended Actions |

|---|---|---|

| Ambient Temperature | High heat can damage electronics and change readings | Use protective enclosures |

| Humidity | Moisture can cause corrosion and short circuits | Choose sealed housings and protective coatings |

| Vibration | Shaking pipes can lead to inaccurate readings | Use supports or vibration isolators |

If you install a flowmeter in a hot or humid area, you should use special housings or enclosures to protect it. In places with a lot of vibration, such as near pumps or heavy machinery, you need to support the meter and use vibration-damping accessories. Always check if your installation location needs special certifications, such as ATEX or IECex, especially in hazardous areas.

- Key points to consider for installation:

- Is the area indoors or outdoors?

- Are there extreme temperatures or high humidity?

- Does the site have strong vibrations or electrical noise?

- Do you need special approvals for hazardous environments?

- Is there enough space for straight pipe runs before and after the meter?

🛠️ Tip: Plan your installation carefully to avoid problems with accuracy and reliability later.

Budget and Maintenance Requirements

When you choose a flowmeter, you need to think about both the price and how much work it takes to keep it running well. Some flowmeters cost more at first but save you money later because they last longer and need less care. Others may have a lower price but need more attention over time.

Here is a table that shows the typical cost range and maintenance needs for different flowmeter types:

| Flow Meter Type | Typical Initial Cost Range | Maintenance Requirements and Durability |

|---|---|---|

| Coriolis | High (due to sophisticated tech and precision) | Highly durable, minimal maintenance, lasts several years in harsh environments |

| Magnetic | Moderate to high (varies by size and application) | Reliable, long service life, low maintenance, non-invasive ideal for corrosive/abrasive fluids |

| Venturi | Generally lower initial cost | Extremely robust, few moving parts, low maintenance but periodic calibration needed |

| Clamp-On | Moderate initial cost | Less durable than fixed models, very low maintenance, easy sensor upkeep, flexible installation |

You will see that a Coriolis flowmeter has a high starting price. You get a device that works for many years and does not need much care. Magnetic flowmeters also last a long time and work well with tough fluids. They do not have moving parts, so you spend less time on repairs. Venturi flowmeters cost less at first and have few parts that can break. You only need to check and calibrate them from time to time. Clamp-on flowmeters are easy to install and move, but they may not last as long as fixed models.

When you look at maintenance requirements, you should know that most modern flowmeters need only simple care. You can follow these steps to keep your flowmeter working well:

- Inspect your flowmeter often for any signs of damage or wear.

- Clean the sensors to remove dirt or buildup.

- Calibrate the flowmeter on a regular schedule to keep readings accurate.

- Check seals, gaskets, and wiring for leaks or loose connections.

- Watch the operating pressure and temperature to avoid damage.

- Always follow the manufacturer’s maintenance guidelines.

🛠️ Tip: If you want to lower your long-term costs, pick a flowmeter with no moving parts and a strong design. These models often have fewer maintenance requirements and last longer in tough conditions.

You should also think about the type of fluid and the place where you will use the flowmeter. Some flowmeters, like electromagnetic and ultrasonic types, work well with dirty or corrosive fluids and need less cleaning. Turbine flowmeters give you precise readings but need more care if the fluid has particles. Vortex and radar flowmeters have no moving parts, so you spend less time on upkeep.

If you plan your budget, remember to include not just the price of the flowmeter but also the cost of regular checks and any spare parts. Good record keeping helps you track when to clean, calibrate, or replace parts. This way, you avoid surprises and keep your process running smoothly.

Flow Meter Installation Best Practices

Pre-Installation Checks and Preparation

You need to start every flow meter installation with careful planning. Pre-installation considerations help you avoid problems later. You should select a location that supports accurate flow measurement setup. Look for a spot with stable temperature and low vibration. Avoid places with strong magnetic interference.

Before you begin, gather all the tools and safety equipment you need. Review the installation requirements and check the documentation for your flow meter. Make sure you have the right meter for your fluid type and process conditions. You should inspect the pipe section to confirm it stays full of liquid. High points in the pipe can trap air and cause errors.

Here are important pre-installation considerations:

- Choose a location free from extreme temperatures and vibrations.

- Check for enough straight pipe runs upstream (5-10 pipe diameters) and downstream (5 pipe diameters) to stabilize the flow profile.

- Use flow conditioners if you cannot provide enough straight pipe length.

- Prepare the site with all necessary tools and safety gear.

- Review the installation details and documentation before starting.

- Perform system checks to verify alignment and connection setup.

- Keep thorough records of installation, test results, and calibration data.

🛠️ Tip: Always confirm the velocity profile at the installation point is symmetrical. This step helps you get accurate readings.

Proper Mounting and Positioning

Proper installation is key to reliable flow meter performance. You must mount the sensor securely to avoid movement and vibration. Stable mounting protects the sensor and ensures accurate readings. You should position the meter so the pipe section remains full of liquid. Avoid high points that can trap air.

Mounting errors can lead to incorrect flow measurement. The table below shows common mistakes and how you can avoid them:

| Common Mounting Errors | Causes | How to Avoid |

|---|---|---|

| Air pockets in pipelines | Air trapped disrupts flow readings | Install air eliminators; position meters properly |

| Pipe blockages or deposits | Scale or sediment restricts flow | Inspect and clean pipelines regularly |

| Temperature/pressure changes | Fluctuations affect measurements | Use meters with compensation features |

| Incorrect meter selection | Wrong meter for fluid properties | Match meter to fluid type and conditions |

| Signal interference | Electrical noise or poor grounding | Use shielded cables and proper grounding |

| Improper installation | Poor placement or pipe sizing | Follow manufacturer guidelines and align correctly |

You should always follow the manufacturer’s instructions for mounting. Secure the meter independently from the pipe to reduce vibration. If you cannot provide enough straight pipe, use a flow conditioner to stabilize the flow. Regularly inspect the pipeline for blockages or buildup. Clean the area before mounting to prevent errors.

⚠️ Note: Never install the meter near pumps or valves that cause turbulence. Turbulence can lead to false readings.

Electrical Connections and Signal Integration

You need to connect the flow meter to your control system for real-time monitoring. Electrical connections must be secure and follow installation requirements. Use shielded cables to prevent signal interference. Proper grounding is important, especially for electromagnetic flow meters.

Flow sensor measurements travel through wired connections to a device called a transmitter. The transmitter converts the signal into a standard output, such as a 4-20 mA analog signal or a digital protocol like Profibus PA or IO-Link. You can send data to the cloud using cellular signals for remote monitoring.

The table below explains key aspects of electrical connections and signal integration:

| Aspect | Description |

|---|---|

| Transmitter Function | Converts small DC voltage from fluid flow into signals for control systems. |

| Signal Outputs | Includes 4-20 mA analog and digital protocols for integration. |

| Grounding for Metal Pipes | Bond and ground flanges and transmitter casing to prevent stray voltages. |

| Grounding for Non-Conductive Pipes | Use grounding rings as recommended, especially for low-conductivity fluids. |

| Signal Measurement | Transmitter outputs volumetric flow rate proportional to fluid velocity. |

| Signal Transmission | Electrodes sense voltage; transmitter processes and sends flow rate signal to control system. |

You can integrate the flow meter with SCADA or other control platforms. This setup allows remote monitoring and real-time alerts. You may combine multiple sensors in one device for a complete system. Always check the manufacturer’s guidelines for electrical connections and signal integration.

💡 Tip: Keep all wiring neat and labeled. Good organization helps you troubleshoot problems quickly.

Initial Calibration and Setup

You need to perform initial calibration and setup after completing the flow meter installation. This step helps you achieve accurate readings and reliable operation. You should always follow a careful process to avoid errors and ensure calibration accuracy.

Start by powering up your flow meter. Let it run for at least 30 minutes. This preheating period stabilizes the system and prepares it for calibration. Next, fill the sensor completely with the calibration fluid. Close downstream valves to prevent fluid from escaping. You must use the same calibration medium for both your flow meter and the calibration standard. This practice avoids measurement errors caused by leaks or temperature changes.

Perform a zero-point adjustment. This step sets the baseline measurement and ensures your readings start from the correct value. Check for overflow signals in your calibration setup. Overflow signals help you confirm that the system operates properly. Circulate the calibration fluid and inspect the system for leaks, especially at seals. Leaks can cause inaccurate readings and damage your equipment.

Gradually open valves to adjust flow rates. You need to reach stable calibration points. Maintain flow stability within ±1-2% of the nominal flow. Keep the temperature within ±1°C during calibration. These conditions help you match the flow meter’s actual operating environment, including fluid viscosity, density, and temperature.

You should perform accuracy tests at different flow rates. Compare the readings from your device under test with the calibration standard. This real-time comparison helps you identify any errors and make adjustments. After calibration, shut down the system by closing valves in sequence, stopping pumps, and draining the calibration fluid. Document the entire calibration process. Good records help you track post-installation considerations and schedule regular recalibrations as recommended by the manufacturer or industry standards.

📝 Tip: Always perform flow meter calibration under conditions that closely match your process environment. This practice improves calibration accuracy and ensures reliable measurements during daily operation.

You should also plan for post-installation accuracy tests. These tests confirm that your flow meter installation meets your process requirements. Regular post-installation considerations include checking for leaks, verifying sensor alignment, and reviewing calibration records. These steps help you maintain long-term accuracy and reliability.

Safety Precautions During Installation

You must follow safety precautions during the installation process to protect yourself and your equipment. Safety starts before you begin work. Review the manufacturer’s safety guidelines and gather all necessary protective gear. Wear gloves, safety glasses, and appropriate clothing for the job.

Check the work area for hazards. Look for wet floors, exposed wires, and moving machinery. Make sure the power supply is off before you connect electrical components. Use insulated tools when working with wiring. Always confirm that the pipe is depressurized and drained before you start the flow meter installation.

You should use proper lifting techniques when handling heavy flow meters. Ask for help if the device is too large or awkward to move alone. Secure the meter to prevent it from falling or shifting during installation. Avoid installing the meter near sources of strong magnetic fields or vibration. These conditions can affect sensor performance and create safety risks.

Follow lockout and tagout procedures when working with electrical systems. This step prevents accidental startup and protects you from electric shock. Use caution when working with calibration fluids. Some fluids may be hazardous or corrosive. Read the safety data sheet and handle chemicals according to recommended practices.

The table below shows important safety checks for flow meter installation:

| Safety Check | Why It Matters | What You Should Do |

|---|---|---|

| Power Off | Prevents electric shock | Turn off power before wiring |

| Personal Protective Equipment | Protects against injury | Wear gloves, glasses, and clothing |

| Area Inspection | Avoids slips and accidents | Check for hazards before starting |

| Lockout/Tagout | Prevents accidental startup | Use lockout devices on power supply |

| Chemical Handling | Prevents exposure to harmful fluids | Follow safety data sheet guidelines |

| Secure Mounting | Prevents equipment damage | Use supports and proper fasteners |

⚠️ Note: Never rush the installation process. Take your time to follow each safety step. Careful planning and attention to detail help you avoid accidents and ensure a successful flow meter installation.

After installation, continue to monitor the area for safety. Post-installation considerations include checking for leaks, verifying electrical connections, and inspecting mounting supports. These steps help you maintain a safe and efficient work environment.

Installation and Maintenance Guidelines for Sensor Flow Meters

Routine Inspection and Cleaning Procedures

You keep your sensor flow meters working well by following routine inspection and cleaning steps. Regular checks help you spot problems early and avoid costly repairs. You should inspect sensors for dirt, wear, or damage, especially around connectors and housings. Clean the flow meter at least once a year, or more often if you work in harsh conditions. Use cleaning agents that do not harm the materials. Wipe sensors and accessories with lint-free cloths and safe solvents. Avoid touching sensitive parts. Check all connections and seals to make sure there are no leaks. Monitor cooling systems like fans or heat sinks to prevent overheating. Replace worn cables and connectors quickly. Keep detailed records of every maintenance activity. These steps help you track performance and spot issues before they grow.

🧰 Tip: Train everyone who handles installation and maintenance to follow best practices. Good training keeps your equipment safe and accurate.

Scheduled Calibration and Performance Verification

You need to schedule flow meter calibration at least every six months. This keeps your measurements accurate and reliable. Use master meter calibration by setting up a master meter and your flow meter in series. Compare readings and record any differences. Create calibration curves and apply correction factors. Gravimetric calibration involves measuring fluid mass with a calibrated balance and recording the time. Piston prover calibration uses a reference standard to check your flow meter’s accuracy. Always use NIST-traceable standards with low uncertainty. Perform calibration under conditions that match your normal operation. Keep records of every calibration and update software when needed. Regulations require calibration after installation and recommend repeating it as the manufacturer suggests.

| Calibration Method | Steps |

|---|---|

| Master Meter Calibration | Compare readings, record deviations, create calibration curves, apply corrections |

| Gravimetric Calibration | Measure fluid mass, record time, calculate flow rate, repeat for accuracy |

| Piston Prover Calibration | Use reference standard, run calibration, compare readings, apply correction factors |

📋 Note: Always calibrate your flow meter after installation and during post-installation checks to maintain accuracy.

Preventing and Identifying Common Errors

You can prevent most errors by following installation guidelines and maintenance best practices. Scaling, sludge, rust, and slime often build up inside pipes and sensors. Clean your system regularly and use filters to keep fluids clear. Secure pipes to reduce vibration. Monitor flow patterns and use dampeners to control pulsating flow. Place meters away from valves and bends to keep a stable flow profile. Inspect for wear and tear, corrosion, or contamination. Replace damaged parts quickly. Schedule routine calibration to stop readings from drifting. Choose meters that match your operating conditions and watch for changes in temperature or pressure. Keep detailed maintenance records to spot recurring problems.

⚠️ Alert: Improper installation causes many errors. Always follow installation guidelines and check for enough straight pipe before and after the meter.

Record Keeping and Documentation

You need strong record keeping to support every sensor flow meter installation. Good documentation helps you track calibration, installation, and maintenance activities. You can use these records to prove compliance and improve your process.

You should start by creating a log for each flow meter. Write down the installation date, location, and the person who performed the installation. Add details about the pipe size, fluid type, and any special conditions. This log helps you find information quickly when you need to check or repair the meter.

During calibration, you must record the procedures you follow. List the equipment you use and the environmental conditions. Write down the calibration results and any adjustments you make. You should keep a calibration history for each meter. This history shows how the meter performs over time and helps you trace any changes. Always make sure your calibration records match the actual operating environment. If you calibrate under different conditions, your documentation may not reflect real performance.

For maintenance, you need to document every activity. Record the date, type of maintenance, and the person responsible. Note any cleaning, repairs, or part replacements. If you find damage or wear, describe it in detail. You should also keep track of the flow rate during calibration and confirm that the media measured by the calibration standard matches what the flow meter measures.

📝 Tip: Good documentation supports quality assurance and audit trails. You can use these records to show compliance with industry standards.

Here is a simple table to help you organize your records:

| Activity | Date | Person Responsible | Details/Results |

|---|---|---|---|

| Installation | 2024-06-01 | J. Smith | Pipe size: 2", Water, Indoor |

| Calibration | 2024-06-10 | A. Lee | Used NIST standard, Adjusted zero |

| Maintenance | 2024-07-05 | M. Patel | Cleaned sensor, Replaced gasket |

You should review your documentation regularly. Update records after every installation, calibration, or maintenance event. This habit helps you spot trends and plan future installation and maintenance schedules.

Troubleshooting Sensor Flow Meter Issues

Resolving Inaccurate Readings

You may notice that your sensor flow meter gives inaccurate readings. Many factors can cause this problem. The table below shows common causes and how you can fix them:

| Cause | Explanation | Troubleshooting Steps |

|---|---|---|

| Improper Meter Selection | Wrong meter for your fluid or process | Choose a meter that matches your fluid and conditions |

| Poor Installation | Meter not aligned or placed correctly | Follow the manufacturer's instructions for installation |

| Air Bubbles or Gas Entrapment | Air in the pipe disrupts readings | Install air eliminators and position meters to avoid air pockets |

| Pipe Blockages or Deposits | Dirt or scale blocks the flow | Inspect and clean pipes often |

| Temperature & Pressure Changes | Fluctuations affect flow measurement | Use meters with compensation features |

| Signal Interference | Electrical noise distorts signals | Use shielded cables and proper grounding |

| Calibration Errors | Incorrect calibration leads to wrong readings | Calibrate your meter regularly |

You should also check for missing pulses in electronic flow sensors. Use interrupts in your code to count every pulse. Avoid delays and blocking loops. Test your setup to make sure you do not miss any signals. Good maintenance and careful setup help you keep your flow measurement accurate.

Addressing Signal Loss and Interference

Signal loss and interference can stop your flow meter from working well. You might see alarms or strange readings. To fix these issues, follow these steps:

- Watch for alarms or abnormal readings. Check grounding because grounding faults often cause signal errors.

- Inspect all cable connections. Replace damaged cables right away.

- Make sure your sensor and converter work together. Incompatible parts can cause wrong readings.

- Use electrical tags and reconnect cables carefully. Ground the shielding layer with low resistance.

- Check the power supply and look for broken parts if the display does not work.

Keep your flow meter away from sources of electromagnetic interference. Clean electrodes and use flow tubes to prevent air bubbles from affecting your flow measurement. Upgrading to smart sensors with better signal processing can also help. Regular maintenance keeps your system running smoothly.

Managing Sensor Drift and Wear

Sensor drift and wear can change your flow measurement over time. You may see sudden spikes or drops in readings, or notice that your meter needs frequent recalibration. Common signs include:

- Loss of accuracy from worn parts or sensor fatigue

- Buildup of debris or scale on sensors

- Increased pressure drop or flow resistance

- Visible damage or corrosion

To manage these problems, perform routine calibration checks and compare your readings with a trusted reference. Clean your sensors and pipes as part of your regular maintenance. Use filters and strainers to protect your meter from dirt. Choose meters that fit your fluid and environment. If you see repeated problems, consider replacing the meter. Monitoring diagnostics in digital meters can give you early warnings. Good maintenance and careful monitoring help you keep your flow measurement reliable.

Environmental and Process-Related Challenges

You face many challenges when you install and operate sensor flow meters in real-world environments. Temperature changes, humidity, and particles in the fluid or air can all affect how your sensor works. These factors can make it hard to get accurate readings and keep your system reliable.

Temperature fluctuations can cause electronic parts inside your sensor to drift. When this happens, your flow meter may show numbers that are too high or too low. High humidity can also create problems. Moisture can get inside the sensor and cause malfunctions. Sometimes, water vapor absorbs infrared light, which leads to overestimation in particulate sensors. You may notice that humidity changes the way your sensor responds, especially if you use low-cost models.

Particles in the fluid or air can overwhelm your sensor. If there are too many particles, your sensor may reach saturation and stop giving correct readings. Over time, exposure to dust or sludge can degrade sensor components. This makes calibration less stable and reduces sensitivity. You need to watch for sensor drift and plan regular maintenance to keep your flow meter working well.

Here are some common environmental and process-related challenges:

- Temperature and humidity can change sensor accuracy and stability.

- High humidity may cause particle aggregation, which affects light scattering measurements.

- Extended exposure to particulate matter can degrade sensor parts and reduce accuracy.

- Low-cost sensors are more likely to show drift and need more frequent maintenance.

- Sensor response stability decreases over time, especially in harsh environments.

You can use advanced calibration methods and correction models to improve data quality. Some systems use neural networks to adjust for environmental changes. You should test your sensor in the actual environment before you rely on its readings. Ongoing calibration and proper maintenance help you avoid problems and keep your sensor flow meter reliable.

🛠️ Tip: Always check your sensor’s calibration and schedule maintenance to prevent drift and keep your measurements accurate.

You can achieve reliable flow measurement by following proven steps.

- Select the right flow meter for your fluid and process needs.

- Install meters with enough straight pipe runs and proper alignment.

- Clean and calibrate your sensors regularly to maintain accuracy.

- Use digital monitoring and predictive maintenance to spot problems early.

🛠️ Tip: Train your team and keep good records. These habits help you save energy, reduce costs, and keep your system running smoothly.

FAQ

What is the most important step before installing a sensor flow meter?

You should always check the fluid type and pipe size first. This step helps you choose the right meter and avoid errors during installation.

How often should you calibrate your flow meter?

You should calibrate your flow meter every six months. If you work in harsh environments, check it more often to keep your readings accurate.

Can you use one flow meter for all types of fluids?

No, you cannot. Each flow meter works best with certain fluids. Always match the meter to your fluid’s properties for reliable results.

What should you do if your flow meter shows strange readings?

First, inspect for air bubbles, dirt, or loose wires. Clean the sensor and check all connections. If problems continue, recalibrate the meter.

Do sensor flow meters need special maintenance?

Most sensor flow meters need only basic care. You should clean them, check for leaks, and keep good records. Follow the manufacturer’s instructions for best results.