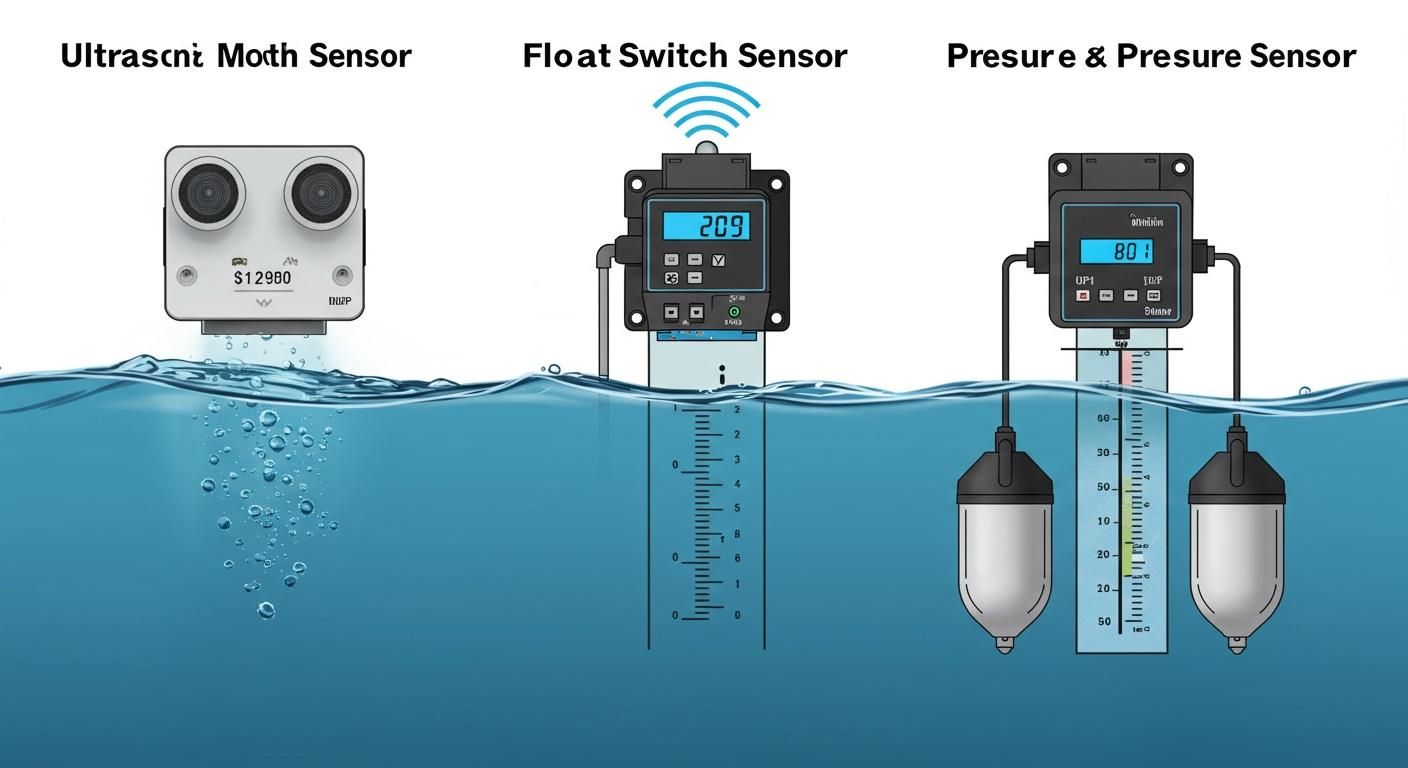

Comparing Ultrasonic Motion Sensors to Other Water Level Detection Methods

You want to know if an ultrasonic motion sensor gives you the most accurate water level readings. Many users report an average error below 3%. Some sensors reach an impressive 0.1% accuracy. You might wonder about possible limitations, such as how changing water surfaces or environmental factors affect results. Choosing the right method depends on your specific needs and the conditions in your application.

- Average error below 3%

- Detected accuracy up to 0.1%

Water Level Detection Technologies Overview

When you explore water level detection, you find several types of technology in use today. Each technology offers unique features and benefits for measuring water in different environments. The table below shows some of the most common technologies used in industrial and municipal settings:

| Technology Type | Description |

|---|---|

| RF Admittance/Capacitance | Uses radio frequency signals to detect material presence or absence, suitable for various conditions. |

| Radar | Employs electromagnetic signals for accurate non-contact level measurement. |

| Magnetostrictive | Detects float position using electric pulses and magnetic fields for precise level measurement. |

| Conductivity Switch | Measures resistance changes when conductive liquids contact probes. |

| Ultrasonic (Point Level) | Uses sound waves to measure liquid levels across an air gap. |

| Ultrasonic (Continuous Level) | Measures time taken for ultrasonic pulses to return to determine liquid level. |

| Hydrostatic | Utilizes pressure transmitters to provide analog signals proportional to liquid levels. |

| Float Switch | Indicates specific water levels using a float mechanism, often used in tanks. |

| Vibration/Tuning Fork | Detects frequency shifts caused by media covering the fork, indicating level changes. |

Ultrasonic Motion Sensor for Water Measurement

You use ultrasonic motion sensors for water level detection when you need a non-contact solution. This technology emits high-frequency sound waves toward the water surface. The sensor measures the time it takes for the sound waves to bounce back. You then get an accurate reading of the distance to the water surface. The sensor uses a transmitter and a receiver, both powered by piezoelectric crystals. These crystals convert electrical energy into sound waves and back again. Ultrasonic sensors can measure water levels from 6 inches to over 20 feet, with a resolution as fine as 0.039 inches. You benefit from high noise tolerance and reliable performance in many water applications.

Float-Based Water Level Sensors

Float-based sensors use a simple but effective technology. You see a float that sits on the water surface. As the water rises or falls, the float moves up or down. The sensor tracks this movement to show the current water level. This technology works because the float is less dense than water, so it always stays on top. The float’s position changes as the water level changes, and a switch or sensor records this movement. You need to check these sensors every 6 to 12 months to keep them working well. In clean water, they can last up to 10 years, but harsh conditions may shorten their lifespan.

Tip: Regular maintenance helps float-based sensors provide accurate water level detection for many years.

Capacitive Water Level Sensors

Capacitive sensors use a different technology for water level detection. You find that these sensors measure changes in capacitance between two plates. When water fills the space between the plates, the capacitance increases. The sensor’s electronic circuit, called a capacitance bridge, tracks this change. This method works well because water has a much higher dielectric constant than air. As the water level rises, the sensor detects the change and gives you a continuous reading. Capacitive sensors work in many environments and can handle different types of water and other liquids.

Radar Water Level Sensors

You can measure water levels with radar sensors when you need high accuracy and reliability. Radar sensors use electromagnetic waves to detect the distance to the water surface. The sensor sends out radar pulses, which bounce off the water and return to the receiver. The time it takes for the waves to travel to the water and back helps you calculate the exact level.

Key parts of a radar sensor include:

- Transmitter: Sends out high-frequency electromagnetic waves.

- Antenna: Directs the waves toward the water and receives the reflected signals.

- Receiver: Picks up weak signals and filters out noise.

- Signal Processing Unit: Analyzes the time delay and adjusts for environmental changes.

Radar sensors work well in harsh conditions. You can use them with aggressive chemicals or foaming liquids. These sensors focus their transmission signals, which helps you get precise readings even when the water surface is rough or moving.

Note: Radar sensors require very little maintenance. You can rely on them for long-term water monitoring in tough environments.

Here is a comparison between radar and ultrasonic sensors:

| Feature | Radar Sensors | Ultrasonic Sensors |

|---|---|---|

| Precision | High accuracy and long-range capabilities | Less precise, good for simple water tasks |

| Maintenance | Very little maintenance needed | More maintenance required |

| Cost | Higher price for advanced models | More affordable and lightweight |

| Versatility | Works in harsh conditions | Limited in harsh water environments |

You may find radar sensors more expensive, but they offer better performance for complex water level detection needs.

Pressure Water Level Sensors

You can use pressure sensors to measure water levels by detecting hydrostatic pressure. The sensor sits below the water surface and measures the force from the water column above it. As the water level rises, the pressure increases. You can calculate the water level using the formula P = ρgh, where P is pressure, ρ is fluid density, g is gravity, and h is the height of the water.

Pressure sensors work well in many water environments. You need to choose sensors with the right Ingress Protection (IP) rating. This rating tells you how well the sensor can handle moisture and dust. If you use the sensor outdoors or in dirty water, pick one with a high IP rating. Environmental factors like contaminants can affect how well the sensor works and how long it lasts.

- IP ratings help you select the best sensor for your water application.

- Consider the environment before installing a pressure sensor.

- Pressure sensors give you reliable water level readings in tanks, wells, and open bodies of water.

Tip: Always check the sensor’s IP rating to make sure it fits your water monitoring needs.

Ultrasonic Water Level Sensors: Accuracy, Strengths, and Limitations

Ultrasonic Sensor Accuracy in Water Level Detection

When you use ultrasonic water level sensors, you often want to know how accurate your readings will be. Ultrasonic sensor accuracy depends on several factors. Air temperature can change the speed of sound, which affects your measurements. For example, a 20°C shift may cause errors of -8.5 cm at 70°C and +7.65 cm at -25°C. Humidity usually does not change results at room temperature, but it can matter at higher temperatures. Air pressure and currents have little effect on ultrasonic water level sensors. You should always check the accuracy specifications for your sensor before installing it in a tank or open water. These sensors can detect water levels with high precision, but you need to consider the environment to get the best results.

Advantages of Ultrasonic Motion Sensors

Ultrasonic motion sensor models give you many benefits when you detect water levels. You do not need to touch the water, so you avoid contamination and wear. Some ultrasonic water level sensors have self-cleaning features, which help reduce downtime. You can use ultrasonic sensors in dark or dirty places because they do not rely on light or color. These sensors work well in tanks, rivers, and reservoirs. You find that ultrasonic technology is cost-effective, with prices starting at $29.95. You can easily integrate ultrasonic motion sensors with microcontrollers for automatic water level monitoring. The sensors have no moving parts, so they last longer in harsh conditions. You can rely on ultrasonic water level sensors for continuous measurement in many applications.

Tip: Ultrasonic sensors are safe to use around people and equipment, making them ideal for industrial and municipal water systems.

Limitations in Water Applications

You need to know the limitations of ultrasonic water level sensors before you choose them for your tank or water project. Turbid water can weaken the ultrasonic waves, causing signal loss and less accurate readings. Suspended particles may create false echoes, which can confuse the sensor and give you wrong water level data. Foam and air bubbles in the water can block signals and add noise, making it harder for ultrasonic sensors to detect water levels. Over time, particles may build up on the sensor’s transducer, which can lower performance. You must clean and calibrate ultrasonic water level sensors regularly to keep them working well. Environmental factors, such as temperature changes and surface conditions, can also affect accuracy specifications. You should always review the limitations of ultrasonic technology before installing sensors in tanks or open water.

| Strengths | Limitations |

|---|---|

| Non-contact measurement | Operating range can limit effectiveness |

| Adaptability to various media | Environmental factors can affect accuracy |

| Cost-effectiveness | Foam and surface conditions can interfere |

| Obstructions and interference can disrupt | |

| Requires regular calibration and maintenance |

Note: You should consider both the strengths and limitations of ultrasonic water level sensors to make the best choice for your application.

Comparing Other Water Level Detection Methods

Float-Based Sensors: Reliability and Simplicity

You often see float-based sensors in water tanks and small reservoirs. These sensors use a float that rises and falls with the water. You get a simple way to measure the water level. Float-based sensors stand out for their reliability and easy installation. You do not need complex wiring or programming. You can trust them in harsh conditions, such as after a flood or in dirty water.

Here is a quick comparison:

| Feature | Float-based Sensors | Other Methods (e.g., Ultrasonic) |

|---|---|---|

| Simplicity | High | Moderate to Low |

| Reliability | High | Variable |

| Installation Complexity | Low | High |

| Maintenance Needs | Minimal | Moderate to High |

| Measurement Precision | Low | High |

You can install these sensors quickly. You only need basic tools. You should check them regularly to keep them working well. You may need to clean the float or inspect for damage. If you use the sensor in a tank with turbulent water, you might see less accurate readings. Float-based sensors work best for simple water level monitoring.

Tip: Set reminders to inspect your float-based sensor after heavy rain or flooding. This helps you catch problems early.

Capacitive Sensors: Sensitivity and Maintenance

You use capacitive sensors when you need high sensitivity in water detection. These sensors measure changes in capacitance as the water level rises or falls. You can detect pure water and low-conductivity liquids with great accuracy. Capacitive sensors work well in environmental monitoring and industrial processes.

| Feature | Description |

|---|---|

| Sensitivity | High sensitivity with 3.3 × 10^5 pF/RH |

| Detection Range | 11% to 98% relative humidity (RH) |

| Response | Exceptional response at high humidity |

| Applications | Environmental, healthcare, industrial |

You benefit from less maintenance because these sensors resist surface contamination. You still need to calibrate them often. Temperature and humidity changes can affect readings. You may see calibration drift, which means you must adjust the sensor to keep it accurate. If you use capacitive sensors in a tank, you should check for material buildup and test the sensor’s output against the actual water level.

- Capacitive sensors tolerate environmental changes.

- You can reduce maintenance by choosing sensors with compensation features.

- You need to watch for calibration drift and temperature effects.

Radar Sensors: Precision and Cost

You choose radar sensors when you want precise water level measurements. Radar sensors use electromagnetic waves to detect the water surface. You get accurate readings even in rough or foaming water. These sensors work well in large tanks and open reservoirs.

Radar sensors cost more than float-based or capacitive sensors. You pay for advanced technology and high reliability. You do not need much maintenance. You can use radar sensors in places with aggressive chemicals or extreme weather. You get long-term performance and stable readings.

- Radar sensors provide high precision in water level detection.

- You spend more upfront but save on maintenance.

- You can rely on radar sensors in harsh environments.

Pressure Sensors: Versatility and Environmental Impact

You can use pressure sensors in many industries because they offer great versatility. In water monitoring, you place the sensor below the surface to measure the force from the water above. This method works well in a tank, a river, or even a well. You get accurate and real-time data about the water level, which helps you make quick decisions.

Pressure sensors do more than just measure water. You find them in HVAC systems to check airflow, in healthcare to monitor patients, and in agriculture to help crops grow better. The table below shows how different industries use pressure sensors:

| Industry | Application Description |

|---|---|

| HVAC | Monitor airflow and detect maintenance needs, enhancing safety and efficiency. |

| Healthcare | Used in breathing apparatus and patient monitoring systems for accurate data. |

| Environmental | Ensures compliance with safety regulations by providing real-time atmospheric data. |

| Robotics | Integral for various robotic applications. |

| Agriculture | Monitors conditions for optimal crop growth. |

| Refrigeration | Used to maintain proper temperature and pressure levels. |

| Water Level | Provides accurate and reliable measurements for water level monitoring. |

You benefit from pressure sensors because they give you continuous data and need little maintenance. They last a long time, even in tough environments. Unlike manual gauges, you can access your data easily and see trends over time.

However, you should know about some environmental impacts when you use pressure sensors for water monitoring:

- Heavy water flows and debris can damage your equipment, causing data loss.

- Saltwater during storms may corrode your sensor.

- Urban areas with lots of pavement make it harder for water to reach underground, which can affect your readings.

- If your well is too narrow or you place the sensor in the wrong spot, your data may not be accurate.

- Dirt and sediment can build up on the sensor, blocking it and making your readings less reliable.

- Battery-powered sensors may lose power, risking gaps in your water data.

Tip: Clean your sensor often and check its placement to keep your water monitoring system working well.

Direct Comparison: Ultrasonic Motion Sensor vs. Other Methods

Accuracy and Precision Across Technologies

When you monitor water level, you want to trust your readings. Each sensor type gives you different results for accuracy and precision. You can see these differences in the table below:

| Sensor Type | Accuracy Level | Precision Level | Environmental Sensitivity |

|---|---|---|---|

| Ultrasonic | Lower accuracy compared to radar | Generally lower precision in tough settings | Affected by temperature, humidity, steam, dust |

| Capacitive | High accuracy for liquids | High precision, detects small changes | Sensitive to dielectric constant, environment |

| Radar | Highest accuracy | Superior precision | Highly resistant to interference |

You use ultrasonic sensors when you need a non-contact way to detect different levels of water. These sensors work well for basic tank level monitoring and water tank level monitor systems. However, if you need the highest measuring accuracy, radar sensors give you better results. Capacitive sensors also offer high accuracy, especially in clean water or wastewater monitoring.

If you want to predict floods or need flood detection, radar sensors help you get the most reliable data. They handle rough water surfaces and changing weather better than other types. You should choose the sensor that matches your application and the level of accuracy you need.

Environmental Sensitivity and Water Conditions

You must think about the environment when you pick a sensor for water level monitoring. Each technology reacts differently to changes in temperature, humidity, and water movement.

- Ultrasonic sensors can lose accuracy if the air temperature or humidity changes quickly. Wind, steam, or dust in the air can also affect the readings. Some ultrasonic models use temperature compensation to help keep the data correct.

- Radar sensors resist most environmental changes. You can use them in places with strong wind, heavy rain, or lots of dust. These sensors use smart algorithms to filter out noise from water turbulence.

- Capacitive sensors work well in stable environments. If the water has a lot of minerals or the air is very humid, you may see changes in the readings. You need to calibrate these sensors often to keep them accurate.

- Pressure sensors can handle many water conditions, but dirt or debris can block the sensor. You should check the sensor’s seal and clean it if needed.

If you work in wastewater monitoring or need an important technology in water level detection for outdoor use, radar sensors give you the best reliability. For indoor tanks or clean water, ultrasonic and capacitive sensors work well.

Tip: Always match your sensor choice to the water and air conditions in your application. This helps you get the best results for monitoring and predicting floods.

Maintenance, Durability, and Cost

You want a sensor that lasts a long time and does not cost too much to maintain. The table below shows what you can expect for cost and care:

| Sensor Type | Cost (Sensor Only) | Maintenance Needs |

|---|---|---|

| Ultrasonic | $120 – $2,600 | Needs regular visual checks and cleaning. If you use harsh cleaners, you must take the unit apart. |

| Pressure | $360 – $1,800 | Needs only simple checks of the seal and housing. Clean the diaphragm with water or air if needed. |

| Radar | $120 – $2,600 | Needs cleaning if liquids build up. You must take the unit apart for deep cleaning with detergents. |

You find that ultrasonic and radar sensors cost about the same, but radar sensors last longer in harsh environments. Pressure sensors cost more, but you do not need to clean them as often. Capacitive sensors need regular calibration, but you do not have to take them apart for cleaning.

If you use a water tank level monitor in a clean setting, ultrasonic sensors give you good value. For outdoor or industrial applications, radar sensors offer better durability and reliability. Pressure sensors work best when you need a tough sensor for many types of water.

Note: Regular maintenance keeps your sensor working well and helps you avoid problems with water level monitoring.

You can use these sensors for many applications, such as tank level monitoring, flood detection, and wastewater monitoring. Each sensor type helps you measure water and detect different levels of water with the right balance of cost, durability, and reliability.

Application Suitability and Best Use Cases

You want to choose the right technology for your water monitoring needs. Each sensor works best in certain situations. You need to think about the environment, the type of water, and how often you want to check the water level. You also want to know which sensor gives you the best accuracy for your applications.

You can see how different technologies fit common water monitoring jobs in the table below:

| Technology Type | Application Areas |

|---|---|

| Ultrasonic Sensors | Flood monitoring, water wells, storage tanks |

| Pressure Transducers | Boreholes, deep wells, municipal water supply systems |

You use ultrasonic sensors when you need to measure water in open spaces. These sensors help you track floods and check water in wells or tanks. You do not need to touch the water, so you avoid damage from dirt or chemicals. You get good results in places where the water surface moves or changes quickly. You can rely on ultrasonic sensors for fast alerts during floods.

Pressure transducers work well in deep water. You use them in boreholes and wells where you need to know how much water is below ground. You also find these sensors in municipal water supply systems. You get strong readings even when the water is dirty or full of minerals. You do not need to worry about surface foam or bubbles. Pressure sensors last a long time and need little care.

You want to match the sensor to your job. Here are some tips to help you decide:

- Use ultrasonic sensors for flood monitoring and storage tanks. You get quick readings and easy setup.

- Choose pressure transducers for deep wells and city water systems. You get strong data and long life.

- Think about the water conditions. If the water is clean and the surface is calm, ultrasonic sensors work well. If the water is deep or full of debris, pressure sensors give you better results.

- Check the accuracy you need. For flood alerts, you want fast and reliable data. For city water, you need sensors that last and keep working with little maintenance.

Tip: Always test your sensor before you install it. You want to make sure it fits your water monitoring needs.

You can use these sensors in many applications. You find them in farms, factories, and city water plants. You get better safety and save money when you pick the right sensor for your water job.

You want the best accuracy and reliability for water measurement. Ultrasonic sensors give you strong precision and steady results, especially when you need to track the water level over time. Pressure sensors also work well and cost less in some cases. When you choose a sensor, think about the liquid type, tank size, and working conditions. For food or chemical plants, non-contact sensors like radar or ultrasonic are a smart choice. In simple tanks, point level devices save money and work well.

FAQ

How do sensors measure water level without touching the water?

You use sensors that send signals, like sound waves or electromagnetic pulses, toward the water surface. The sensor receives the reflected signal and calculates the distance. This method keeps the sensor clean and safe from water damage.

Which sensors work best in dirty or foamy water?

You find radar sensors perform well in dirty or foamy water. These sensors use electromagnetic waves that ignore most surface problems. Pressure sensors also work in harsh conditions because you place them below the water surface.

How often should you clean and check your sensors?

You should inspect sensors every few months. Clean the sensor surface to remove dirt or buildup. Regular checks help you catch problems early and keep your sensors working well. Some sensors need calibration to stay accurate.

Can sensors detect water level changes quickly?

You get fast readings with ultrasonic and radar sensors. These sensors update water level data in seconds. Pressure sensors also respond quickly. You can use these sensors for flood alerts or tank monitoring where speed matters.

What is the most cost-effective sensor for basic water level monitoring?

You save money with float-based sensors for simple jobs. These sensors last a long time and need little maintenance. Ultrasonic sensors also offer good value for tanks and wells. You choose sensors based on your budget and needs.