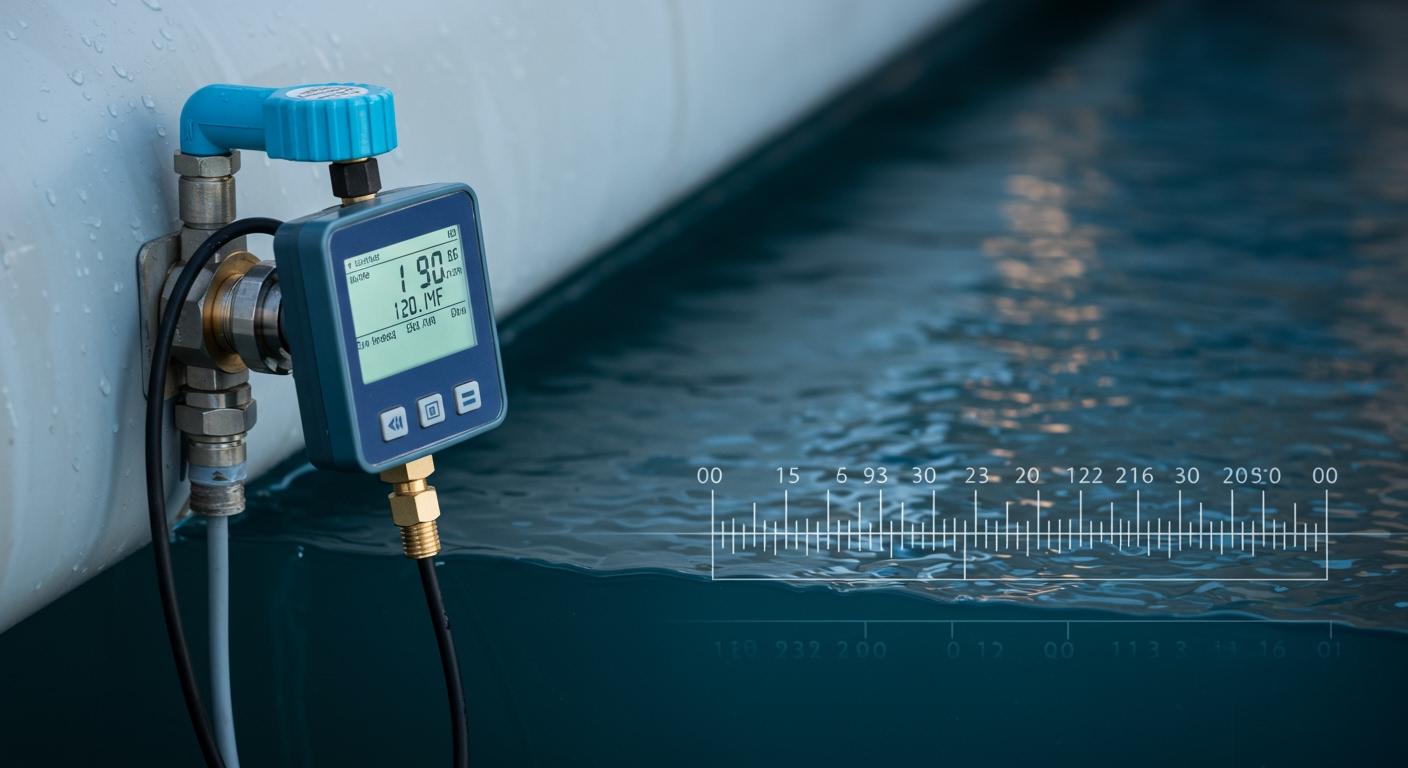

How Water Level Pressure Sensors Work and Why Accuracy Matters

You use a water level pressure sensor to measure how deep water is by detecting the pressure from the water column. This sensor changes the pressure into an electrical signal, so you get real-time water level measurement. Accurate water level monitoring helps you protect communities from floods, keep water distribution systems running smoothly, and maintain safety in many industries.

- Water level sensors give you continuous data for flood warnings.

- You rely on these sensors in water resource management, like cooling towers and water tanks, to avoid equipment damage.

- Industries use water level sensors to track consumption and secure proper water supply.

The global fluid pressure sensors market reached USD 16.85 billion in 2024 and is expected to grow at a CAGR of 7.10%, showing strong demand for these technologies.

Water Level Pressure Sensor Operating Principle

How Pressure Sensing Determines Water Level

You can measure water depth by understanding how pressure changes with depth. When you place a sensor under water, the weight of the water above pushes down on it. This pressure increases as the water gets deeper. Scientists use a simple formula to show this relationship:

| Variable | Description |

|---|---|

| p | Pressure at a point in the water column |

| ρ | Water density |

| g | Local acceleration due to gravity |

| h | Height of the water column above the measuring point (depth) |

The formula looks like this:

p = ρ g h

You can rearrange it to find the depth:

h = p / (ρ g)

This means that if you know the pressure, you can figure out how deep the water is. Water pressure sensors use this principle to give you accurate water level readings. You rely on this method in many places, such as rivers, tanks, and reservoirs. When you use a water level pressure sensor, you get a direct measurement of how much water sits above the sensor.

Tip: Always check the water density and gravity values for your location. These can change slightly and affect your readings.

Pressure-to-Electrical Signal Conversion

You might wonder how a sensor turns water pressure into a number you can read. The process happens in a few steps:

- The sensor measures the hydrostatic pressure from the water above it.

- This pressure reading gets converted to a water level value.

- As the water rises, the pressure on the sensor increases in a predictable way.

Inside the sensor, special electronics detect the pressure change. The sensor then changes this pressure into an electrical signal. You might see this as a voltage, a current (like 4 mA to 20 mA), or a digital signal. This signal travels to a display or a control system, so you can see the water level in real time.

Water pressure sensors help you monitor water levels without needing to look inside a tank or well. You get fast, reliable data that you can use for safety, planning, or daily operations.

Types of Pressure Measurement for Water Level Measurement

When you choose water pressure sensors, you need to know how each type measures pressure. The three main types are absolute, gauge, and differential sensors. Each one works in a different way and fits specific pressure sensor applications.

| Type of Sensor | Reference Pressure | Measurement Description |

|---|---|---|

| Absolute Pressure | Vacuum | Measures pressure relative to a perfect vacuum, consistent regardless of altitude. |

| Gauge Pressure | Local Atmospheric Pressure | Measures pressure relative to local atmospheric pressure, varies with altitude. |

| Differential Pressure | Two Points in a System | Measures the difference in pressure between two points, useful for flow measurement. |

Absolute Pressure Sensors in Water Level Applications

You use absolute pressure sensors when you need a measurement that does not change with local weather or altitude. These sensors measure pressure compared to a perfect vacuum. You often see them in deep wells, boreholes, or reservoirs where venting to the atmosphere is not possible. Absolute sensors help you avoid errors from changing air pressure. For example:

- You can use them in submerged conditions where air cannot reach the sensor.

- They work well in hydrostatic level measurement for groundwater or sealed tanks.

- You get reliable readings even if the weather changes.

Gauge Pressure Sensors for Water Level Measurement

Gauge pressure sensors measure pressure compared to the air around you. You use these sensors in open tanks, rivers, or lakes where the sensor can vent to the atmosphere. The reading changes if the local air pressure changes. This type is common for everyday water level checks. You get a simple setup and easy maintenance.

Differential Pressure Sensors and Water Level Sensing

Differential pressure sensors measure the difference between two points. You use them to track water levels in systems where you need to know the pressure drop, such as in water treatment plants or pipelines. These sensors help you:

- Detect blockages in filtration systems.

- Prevent over-pressurization in water distribution pipes.

- Get real-time data for safe and efficient water management.

You can rely on water pressure sensors to match your specific needs by choosing the right type for your application.

Core Technology of Water Level Pressure Sensors

Transducers and Diaphragms in Sensor Design

You find that the heart of a water level pressure sensor is the pressure transducer. This device converts the force from water into a readable signal. The sensor uses a diaphragm to separate the water from the sensitive electronics. The diaphragm touches the water and bends when the pressure changes. You see this design in closed systems, especially when you measure thick or corrosive liquids. The diaphragm can handle water with lots of particles, so you get accurate readings even in tough conditions.

| Aspect | Description |

|---|---|

| Diaphragm Function | The isolation diaphragm is in contact with the medium over a large area, suitable for closed systems. |

| Application | Particularly effective for measuring viscous or slurry media and strong corrosive liquids. |

| Medium Characteristics | Capable of handling media rich in particles, enhancing measurement accuracy in challenging conditions. |

Strain Gauges and Sensing Elements

You rely on strain gauges inside the pressure transducer to sense changes. These tiny devices stick to the diaphragm. When the diaphragm bends, the strain gauges stretch or compress. This movement changes their electrical resistance. The sensor uses a special circuit called a Wheatstone bridge to measure these changes. You get a precise electrical signal that matches the water pressure.

| Characteristic | Description |

|---|---|

| Mechanical Strain Conversion | Strain gauges convert mechanical strain into electrical signals, enabling accurate pressure measurement. |

| Piezoresistive Effect | Utilizes the change in resistance of strain gauges mounted on a diaphragm to measure pressure changes. |

| Wheatstone Bridge Circuit | Arranges strain gauges in a loop to enhance measurement accuracy and signal output. |

Signal Processing for Accurate Water Level Measurement

You benefit from new technology that makes water level readings more reliable. Modern sensors use wireless communication, so you get real-time data without running wires everywhere. Advanced algorithms help the sensor correct errors and improve accuracy. You can trust these sensors to work well, even in harsh environments. Some pressure transducers use graphene and other new materials. These materials give you better performance and longer life.

- Integration of wireless communication for real-time data transmission.

- Use of advanced algorithms to enhance accuracy and reliability.

- Development of sensors that provide precise measurements in challenging environmental conditions.

- Use of graphene and its derivatives for high-performance pressure sensors.

- Unique mechanical and electrical properties of new materials that enhance sensor capabilities.

Note: You should always check if your sensor uses the latest technology. This helps you get the most accurate water level readings.

Factors Influencing Water Level Pressure Sensor Accuracy

Sensor Specifications and Calibration

You depend on sensor specifications to get reliable water level measurement. Each water level pressure sensor has unique features that affect how well it works in different applications. You need to pay attention to calibration, hysteresis, and manufacturing variations. These factors help you decide which sensor fits your needs.

Here is a table showing the main factors that influence sensor accuracy:

| Factor | Description |

|---|---|

| Calibration | Ensures sensor readings align with true values. |

| Environmental Conditions | Temperature and humidity can affect sensor performance. |

| Hysteresis | Measures the difference in output for the same pressure value during increase or decrease. |

| Manufacturing Variations | Differences in production can lead to variations in sensor accuracy. |

| Application Variables | Includes temperature, specific gravity, dielectric constant, overpressure, shock and vibration, and barometric pressure. |

| Improper Mounting | Incorrect installation can lead to inaccurate readings. |

| Natural Drift | Over time, sensors may drift from their calibrated settings, affecting accuracy. |

You need to calibrate your water pressure sensors regularly. Calibration keeps your readings true and helps you avoid errors. If you skip calibration, your sensor may drift and give you wrong results. Drift happens slowly, but it can cause big problems in flood risk management and other pressure sensor applications.

Calibration is crucial for maintaining the long-term accuracy of water level pressure sensors. It helps to correct for drift, which is a gradual degradation of the sensor's performance over time due to various environmental factors. Regular calibration ensures that the sensor readings remain true to the actual pressure, thereby enhancing reliability and precision in measurements.

You can use these tips to keep your sensors accurate:

- Take regular 'field zero readings' to remove drift.

- Check calibration after any major change in your system.

- Choose sensors with low hysteresis for better repeatability.

You see adjustable errors, systematic errors, and random errors in your readings. You can fix adjustable errors with calibration. Systematic errors need compensation. Random errors are harder to control, but you can reduce them by using high-quality sensors.

Environmental Effects on Water Level Measurement

You face many environmental challenges when you use water level sensors. Temperature and humidity can change how your sensor works. If the temperature goes up or down, your sensor may give you different readings. High humidity can cause condensation on the sensor, which may block signals and lower accuracy.

- Temperature variations can significantly affect the performance of submersible level sensors, leading to inconsistent accuracy if the operational temperature deviates from the tested range.

- High humidity can cause condensation on sensor components, which may interfere with signal transmission and reduce measurement precision.

You need to watch for temperature errors. These errors happen when the fluid density changes. You can use temperature compensation to fix this problem. You also need to check for pressure changes in boilers or tanks. These changes can shift your zero point and make your readings wrong. You can use pressure-compensated transmitters to solve this issue.

Here are some common sources of error and how you can fix them:

| Source of Error | Description | Mitigation Strategy |

|---|---|---|

| Temperature Variation | Changes in temperature affect fluid density, leading to inaccurate pressure readings. | Implement temperature compensation techniques. |

| Boiler Pressure Fluctuations | Variations in pressure can cause zero-point shifts in readings. | Use pressure-compensated DP transmitters. |

| Density Changes in Impulse Lines | Inconsistent fluid density in impulse lines skews differential pressure readings. | Regular maintenance of impulse lines. |

| Installation Position and Orientation | Improper installation can introduce gravitational measurement errors. | Ensure correct installation and alignment. |

| Leakage and Blockage in Impulse Lines | Leaks or blockages can prevent accurate pressure transmission. | Conduct regular maintenance and inspections. |

| Condensate Level Changes | Variations in condensate levels can impact the zero-point of the transmitter. | Maintain stable condensate levels through design. |

You can use advanced transmitter features to help you spot problems early. Smart diagnostics can warn you before a sensor fails. Regular maintenance and proper installation keep your water pressure sensors working well in all applications.

Media Compatibility and Sensor Performance

You need to match your sensor to the liquid you want to measure. Media compatibility means your sensor can handle the chemicals and particles in the water. If you use a sensor in a water purification plant, it must work with both water and chlorine. If you pick the wrong sensor, it may break down or give you bad readings.

- A sensor used in a water purification plant must be compatible with both water and chlorine to function effectively.

- A study indicates that while operation in water may slightly reduce burst pressure, it does not significantly compromise the sensors' performance and reliability.

You see that water pressure sensors last longer when you choose the right materials. Stainless steel and ceramic diaphragms resist corrosion and damage. You also need to think about the pressure transducer design. Some sensors work better in dirty water or with lots of particles. If you use your sensor in tough applications, pick one with a strong diaphragm and good sealing.

You can avoid problems by checking media compatibility before you install your sensor. This step helps you get accurate water level measurement and keeps your sensor working for years. You protect your equipment and improve safety in flood risk management and other pressure sensor applications.

Installation and Placement Impact

When you install a water level pressure sensor, you make choices that affect how well it works. You want your sensor to give you accurate readings every time. The way you place and set up your sensor can change the results you see.

If you put your sensor in the wrong spot, you might get false readings. You need to think about where water moves, how debris collects, and what the environment looks like. You should avoid placing sensors near inlets, outlets, or areas with strong currents. These spots can cause pressure spikes or turbulence. You get better results when you choose a calm area with steady water.

Tip: Always check for obstacles like rocks, pipes, or sludge before you install your sensor. These can block the sensor or change the pressure around it.

You also need to think about how deep you place the sensor. If you put it too close to the surface, you might see changes from waves or wind. If you place it too deep, you could miss small changes in water level. You want to find a spot that gives you a clear picture of the water column.

Here are some best practices for sensor installation and placement:

- Perform calibration and setup by following the manufacturer's instructions. This step helps you get accurate measurements.

- Choose sensors rated for your specific environmental conditions. You improve the sensor's life and performance when you match it to the right setting.

- Establish a routine for cleaning, inspecting, and testing your sensors. Regular maintenance keeps your readings reliable.

You can follow these steps to avoid common mistakes:

- Check compatibility between your sensor and the type of water in your tank. This step helps you keep your measurements correct.

- Avoid mixing metals in your installation. Use the same metal for all parts to prevent galvanic corrosion.

- Use waterproof sensors and cables. This choice protects your system from short circuits and sensor failure.

You need to secure your sensor so it does not move or shift. If your sensor moves, you might see sudden changes in your readings. You can use brackets, clamps, or weights to hold the sensor in place. Make sure the sensor faces the right direction and sits flat against the water column.

You should also think about how you run your cables. Keep cables away from sharp edges and moving parts. Use waterproof connectors to stop water from getting inside. You protect your sensor and your data when you use the right cables.

Note: Regular testing helps you catch problems early. If you see strange readings, check your installation first.

When you pay attention to installation and placement, you get better results from your water level pressure sensor. You make your system safer, more reliable, and easier to maintain.

Why Accuracy Matters in Water Level Measurement

Real-World Impacts of Inaccurate Water Level Pressure Sensor Readings

You depend on accurate water level measurement for many applications. When your water level pressure sensor gives you wrong readings, you face real problems. In wastewater treatment plants, you need precise monitoring to control pumps and filtration systems. If the sensor fails, pumps may run dry or surge, causing equipment damage. You also risk backups in pipes, which can disrupt operations and harm the environment. Accurate readings help you manage flow and keep your system safe. In flood risk management, a small error can mean missing a warning for rising water. You protect communities and property when you trust your sensor to give you the right data.

If you ignore sensor accuracy, you may spend more money fixing equipment or cleaning up spills. You also risk breaking rules set by local authorities.

Safety and Operational Risks

You keep people safe when you use reliable sensors in your applications. In factories and water plants, wrong measurements can lead to dangerous situations. Pumps may run without water, causing overheating or breakdowns. Tanks can overflow if you do not see the true water level. You need sensors that work well in every condition. When you choose the right sensor, you avoid accidents and keep your team safe. You also make sure your operations run smoothly, without sudden stops or costly repairs.

| Risk Type | Example Problem | Result |

|---|---|---|

| Equipment Damage | Dry running pumps | Expensive repairs |

| Flooding | Missed high water warning | Property damage |

| Process Failure | Wrong tank level reading | Production loss |

Regulatory and Compliance Requirements

You must follow strict rules in many applications. Authorities set standards for water level measurement to protect public health and the environment. You need sensors that meet these requirements. When you select and maintain your water level pressure sensor, you should consider several factors:

- Accuracy helps you meet regulatory standards for liquid level detection.

- Material compatibility ensures your sensor can handle the liquid and stay reliable.

- Response time lets you report data quickly, which is important for compliance.

- Environmental conditions matter because your sensor must resist temperature and humidity changes to meet industry rules.

You avoid fines and legal trouble when you use sensors that meet all compliance needs. You also build trust with your customers and your community.

Best Practices for Water Level Pressure Sensor Selection and Deployment

Matching Sensor Type to Application Needs

You need to match the right sensor to your specific application. Each environment has different needs, so you should look at several criteria before you choose. The table below shows what you should consider:

| Criteria | Description |

|---|---|

| Temperature Compensation | Sensors must compensate for temperature changes to maintain accuracy across varying conditions. |

| Barometric Pressure Compensation | Changes in barometric pressure can affect sensor readings, so compensation is needed for accuracy. |

| Sensor Construction | The materials used in sensor construction impact long-term performance and durability. |

| Power Sources | Different sensors may require various power sources, which affects where you can use them. |

| Analog vs Digital Sensors | You need to know the differences between analog and digital sensors for your applications. |

When you select water level sensors, always check if the pressure transducer can handle the temperature and pressure changes in your system. Some sensors work better in outdoor environments, while others fit best in controlled indoor settings.

Installation Techniques for Reliable Water Level Measurement

Proper installation helps you get the most accurate readings from your pressure transducer. Follow these steps to make sure your sensor works well:

- Choose a location that is easy to reach and away from extreme temperatures, humidity, and vibrations.

- Check the sensor for damage and make sure all parts fit together.

- Clean the area, install the sealing gasket, secure the sensor, connect the wiring, and calibrate the sensor.

- Avoid mechanical shocks and keep cables away from electrical interference.

- Use protective guards or baffles if the environment is disturbed.

- Apply petroleum jelly to protect against corrosion and use buffer tubes for high temperatures.

- Install the sensor to reduce the impact of fluid surges.

Tip: Always keep your installation area clean and stable. This helps your water level sensors last longer and work better in all applications.

Maintenance and Calibration for Long-Term Accuracy

You need to maintain and calibrate your sensors to keep them accurate. The frequency depends on your industry and how you use the sensor. The table below shows how often you should calibrate:

| Industry Type | Calibration Frequency | Notes |

|---|---|---|

| Pharmaceuticals | At least twice a year | FDA guidelines require this to ensure safety and accuracy. |

| Food & Beverage | At least twice a year | High accuracy is needed to avoid safety risks. |

| Oil and Gas | Varies, highly regulated | Strict standards help prevent hazardous situations. |

| General Applications | Based on stability and history | Adjust intervals based on the sensor's stability and calibration history. |

Regular maintenance includes cleaning, checking for damage, and recalibrating as needed. When you follow these steps, your water level sensors will give you reliable data for many years.

Troubleshooting Water Level Pressure Sensor Issues

You may notice your water level pressure sensor does not always work as expected. When you see problems, you need to find the cause and fix it quickly. Common issues can affect how your sensor measures water levels. You can use a simple checklist to help you solve these problems.

Most Common Sensor Issues

- Overfilling: You might see water levels rise too high. This can happen if the pressure switch fails, the air dome tube gets blocked, or the control board has a problem.

- Underfilling: Sometimes, water does not reach the right level. A broken pressure switch, a pinched air tube, or a faulty electronic sensor can cause this.

- No Water Filling: If your tank stays empty, you may have a broken sensor, bad wiring, or a control board fault.

- Erratic Water Levels: Water levels may jump up and down. Intermittent sensor faults or loose connections often lead to this issue.

Tip: Always check your sensor readings against manual measurements. This helps you spot errors early.

Steps to Troubleshoot Your Sensor

- Visual Inspection: Look at the sensor and wires. You may find signs of wear, damage, or loose connections.

- Check the Air Dome Tube: Make sure the tube is clear. Blockages can stop the sensor from working.

- Multimeter Testing: Use a multimeter to test the sensor’s continuity. This shows if the sensor works or needs replacement.

- Inspect the Control Board: Examine the board for burnt or damaged parts. Faulty boards can cause sensor errors.

| Problem Type | What to Check First | Quick Fix Suggestion |

|---|---|---|

| Overfilling | Pressure switch, air tube | Clean tube, replace switch |

| Underfilling | Pressure switch, air tube | Unpinch tube, check sensor |

| No Water Filling | Sensor, wiring, control board | Repair wiring, replace sensor |

| Erratic Levels | Connections, sensor | Tighten wires, test sensor |

Note: Regular checks and cleaning help prevent most sensor problems. You keep your system safe and reliable when you follow these steps.

You rely on a water level pressure sensor for accurate water level measurement in many situations. Reliable water level sensors help you predict floods, control irrigation, and protect pipelines.

- Real-time monitoring

- Early detection

- Enhanced safety

- Optimized efficiency

When you follow best practices, you extend sensor life and keep your data trustworthy. Regular calibration and careful installation prevent errors and support long-term reliability.

FAQ

How often should you calibrate a water level pressure sensor?

You should calibrate your sensor at least once a year. If you use it in critical applications, check it every six months. Regular calibration helps you keep your readings accurate and reliable.

Can you use a water level pressure sensor in saltwater?

Yes, you can use these sensors in saltwater. Choose a sensor with corrosion-resistant materials like stainless steel or ceramic. This protects your sensor and ensures long-lasting performance.

What causes inaccurate water level readings?

You may see errors from poor installation, temperature changes, or sensor drift. Dirty sensors and wrong calibration also affect accuracy. Clean and calibrate your sensor regularly to avoid these problems.

How do you know if your sensor is failing?

You notice sudden changes in readings, erratic water levels, or no response from the sensor. Check for damaged wires, blocked tubes, or worn-out parts. Replace faulty sensors to restore proper measurement.

Do water level pressure sensors work in freezing temperatures?

Some sensors work in freezing conditions if designed for low temperatures. Always check the manufacturer's specifications before using a sensor in cold environments. This helps you avoid damage and get accurate readings.