Remote Propane Monitoring: The Expert's Guide to Checking Tank Levels from Your Phone (Cellular vs. Wi-Fi)

The scene is a familiar one for any propane user: the thermometer just dipped below freezing, the furnace is cycling hard, and a vague, nagging fear creeps into your mind. Did I remember to check the tank last week? You brace yourself for the walk outside, lift the dome, squint at the gauge, and hope you don't see 10% or less. If you've ever dealt with an emergency refill or, worse, a costly out-of-gas service call, you know that moment of dread all too well.

For too long, managing your propane supply has been a reactive, guesswork-driven hassle—a system begging for a modern solution.

This is where remote propane monitoring (or propane telemetry) changes the game. By the end of this expert guide, you won't just know what a smart monitor is; you’ll understand the critical differences between cellular and Wi-Fi models, how to install one yourself, and the real-world return on investment (ROI) that makes this technology indispensable for both homeowners and commercial operators.

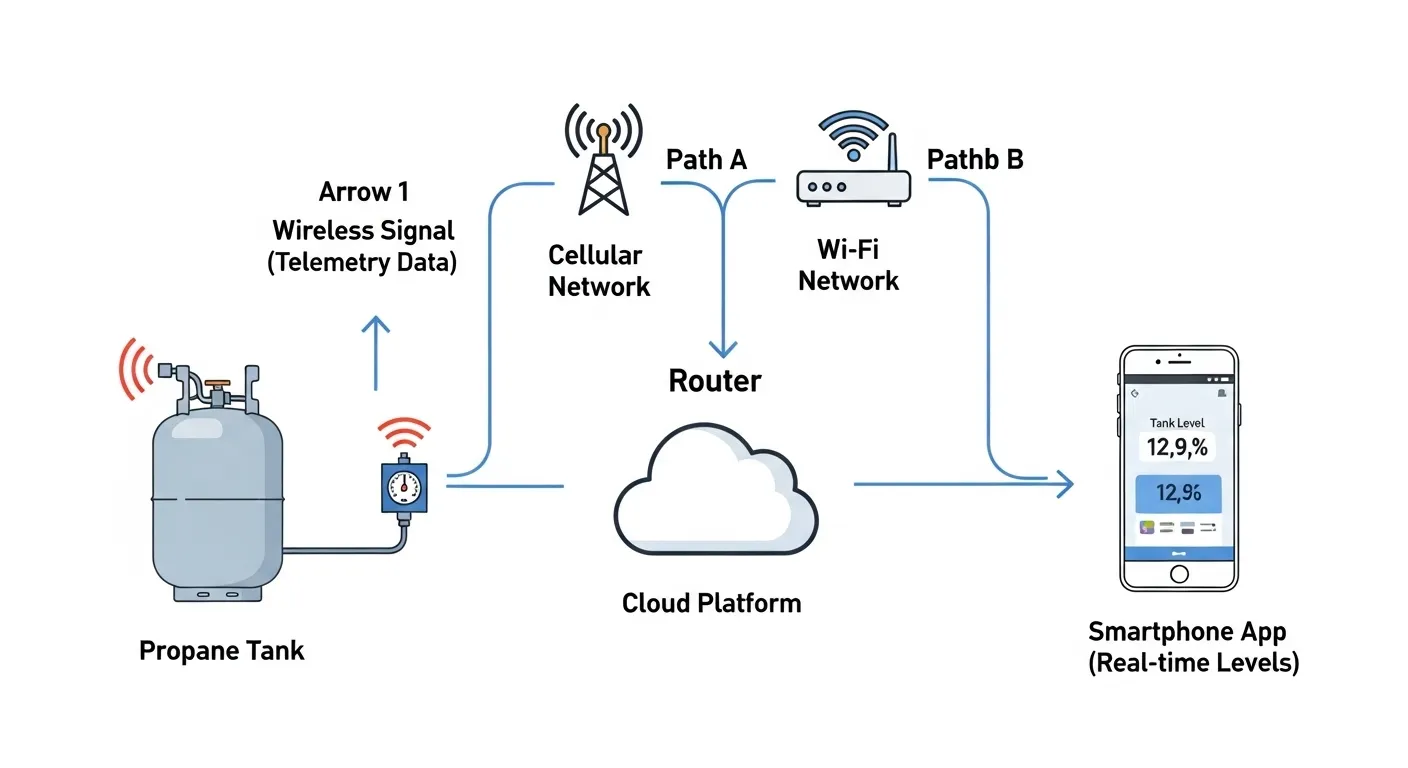

Quick Answer: Remote propane monitoring works by installing a magnetic sensor onto your tank's dedicated R3D-ready gauge. This sensor converts the mechanical liquid level into an electrical signal and transmits the data wirelessly—either via a dedicated cellular network or your home Wi-Fi—to a cloud server, which you access in real-time through a simple smartphone app.

What is Remote Propane Monitoring and Why it Matters

At its core, remote propane monitoring is a technological handshake between a mechanical gauge and the digital world. The industry term you’ll often hear is Propane Telemetry: the automated process of communicating tank level data over a long distance.

For customers and suppliers alike, this technology solves one core, expensive problem: guessing.

Key Components of a Propane Telemetry System

The system that allows you to check your tank level from the golf course or the ski slope has a few essential parts working in concert:

- The Sensor/Transmitter: This small, non-invasive device magnetically or mechanically mounts onto your gauge. It's powered by a long-life battery (more on that later) and transmits the data.

- The Connectivity: This is the radio—Cellular (4G/LPWAN) or Wi-Fi (2.4 GHz)—that sends the data signal to the cloud.

- The Cloud Platform: This is the server where the raw data is logged, processed, and converted into an easy-to-read percentage or gallon count.

- The Smartphone App: Your window into the system, offering real-time levels, usage history, and low-level alerts.

The Financial and Safety Imperative

While "peace of mind" is certainly a benefit for a homeowner, the adoption of RTM in the industrial sector points to a much more tangible value proposition. According to market research, the remote tank monitoring market is projected to see a Compound Annual Growth Rate (CAGR) of over 15% through the next decade, a trend driven by cold, hard numbers.

- For Homeowners: It’s about more than convenience. Running out of gas in the winter can lead to frozen, burst pipes—a catastrophic cost that makes the monitor pay for itself immediately.

- For Commercial Users: Here's where it shines. For facilities relying on backup power, remote monitoring directly supports NFPA 58/99 compliance. These codes require generator fuel reserves to be monitored and alarmed at critical levels. Manual checks are prone to human error; a reliable cellular monitor guarantees compliance and asset protection. Furthermore, suppliers save thousands on reduced truck rolls (delivering only when truly necessary) and eliminating costly emergency, after-hours delivery charges.

The Core Technology: How Propane Tank Sensors Actually Work

Let's get into the mechanics. Most general guides stop at "it has a sensor," but to truly understand reliability, you need to know what’s under the hood. The genius of RTM is its simplicity and reliance on existing, rugged tank infrastructure. Internal Link: See our deep dive on how wireless LP tank monitors work.

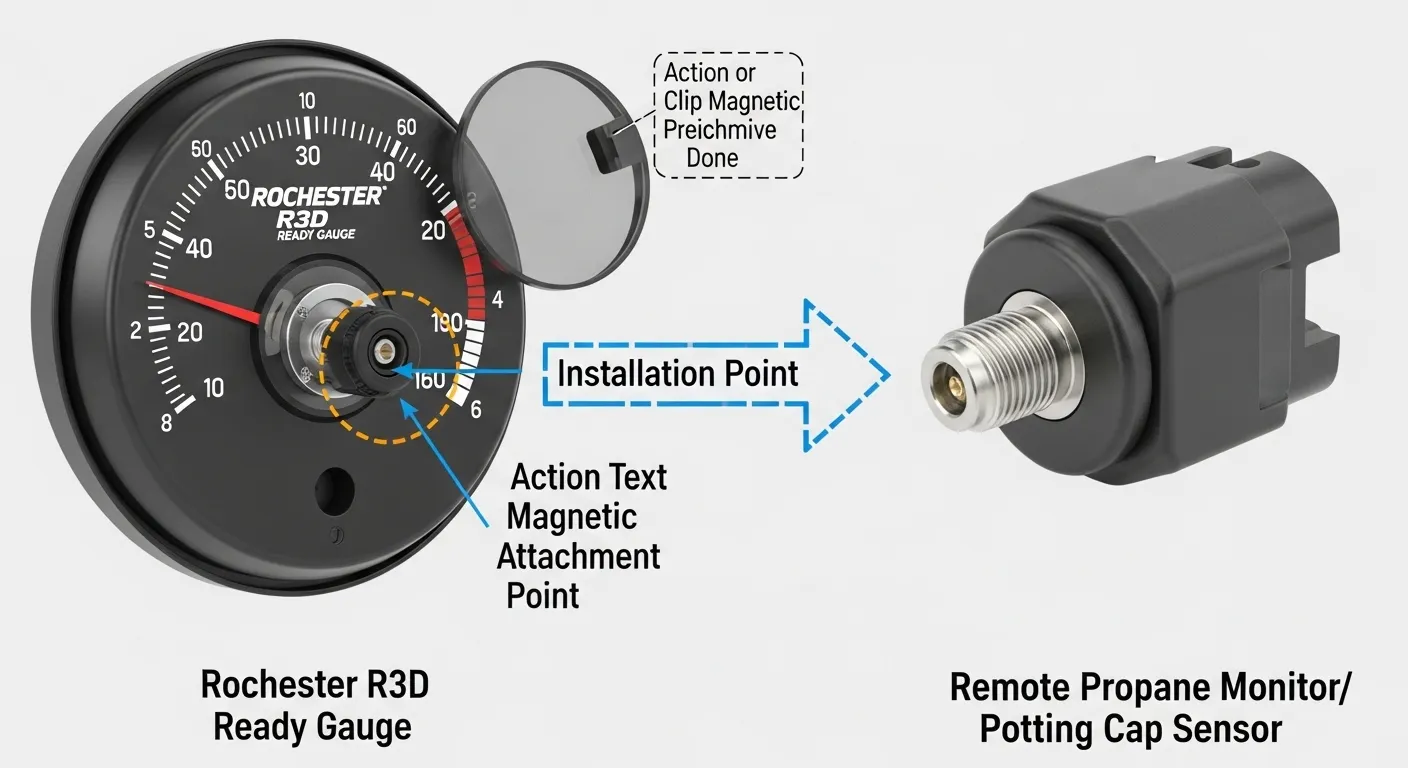

1. The Critical Component: The Remote-Ready Gauge

The star of the show isn’t the monitor itself—it’s the gauge. For non-invasive, reliable remote monitoring, your tank gauge needs to be R3D/Remote-Ready.

This standard, commonly found in Rochester Gauges, means the mechanical float gauge inside the tank is connected to a small magnet within the dial. When you install your remote monitor, you’re clipping or screwing the Potting Cap Sensor directly onto this ready-to-use dial. This sensor then uses a Hall effect sensor to detect the precise angle of that internal magnet, converting the mechanical percentage reading into an electrical signal that the transmitter can send wirelessly.

The takeaway? If your dial isn’t R3D-ready, monitoring becomes far more complicated (and likely requires a professional to swap out the dial).

2. Sensor Types: The Real Mechanics

While the R3D magnetic sensor is the most common for retrofit applications, a few other types exist, and it helps to know their pros and cons:

- Ultrasonic Sensors: These work like a sonar—they bounce sound waves off the surface of the liquid propane. They’re popular because they can simply strap to the outside of the tank (like the Mopeka units). The trade-off? They are often less accurate than magnetic-based systems, as temperature and the non-uniform shape of the tank can affect the reading.

- Magnetostrictive/Pressure Sensors: These are often used for very large commercial tanks or fuel custody transfer. They are highly accurate, using pressure readings or highly specialized probes. The trade-off? High cost and complex installation that requires professional intervention.

Why Tanks Are Only Filled to 80%

One question I hear a lot is, “If my gauge reads 80%, why is my tank considered full?” This isn't a technical error; it's a critical safety measure. Propane is stored as a liquid, and that liquid expands dramatically as the temperature rises. Filling the tank beyond 80% wouldn't leave enough vapor space for that expansion, leading to dangerously high pressure and potential venting (a pressure relief valve release). This 20% margin is non-negotiable, and your monitor accounts for it.

Connectivity Showdown: Cellular vs. Wi-Fi

This is the most crucial decision you'll make when purchasing a remote propane monitor. Choosing the wrong connectivity type is the number one reason I see customers run into reliability issues. Internal Link: Read our comparison of Wi-Fi vs. Cellular Propane Tank Meters.

1. Wi-Fi Propane Monitors: The Consumer Option

Wi-Fi units appeal to the residential consumer because they leverage the home’s existing internet.

- Pros: Generally lower upfront cost, no recurring subscription fee (you’ve already paid for the internet).

- Cons (Trustworthiness/Experience): The single biggest issue is battery drain. Wi-Fi is an energy hog, and a weak Wi-Fi signal forces the device to boost its power to transmit, killing the battery in months. Furthermore, if your home network goes down or your power is out (when you might need that propane level information the most), the monitor is useless.

What I've found is that Wi-Fi range is the #1 killer of battery life. If your tank is 50+ feet from your router or your house has thick masonry, expect to be changing those lithium AAs much sooner than you think.

2. Cellular/LPWAN Propane Monitors: The Professional Standard

Cellular units utilize dedicated, low-power wide-area networks (LPWAN) like Cat-M1 or NB-IoT, which are designed for small data packets and maximum battery longevity. They operate like a dedicated data cell phone, completely independent of your home network.

- Pros: Ultra-long battery life (often 5 to 7+ years), works anywhere there is a reliable cellular signal (perfect for remote locations, cabins, or generator tanks), and offers maximum reliability.

- Cons: Requires a recurring subscription fee (typically $5-$8 per month) to cover the data transmission cost, and the initial hardware cost is usually higher.

| Feature | Wi-Fi (B2C Focus) | Cellular (B2B/Reliability Focus) |

| Connectivity | Local Wi-Fi (2.4 GHz) | Dedicated Cellular (4G/LPWAN) |

| Reliability | Medium (Vulnerable to network outages/power loss) | High (Independent of local network) |

| Subscription | Generally None | Required (For data transmission) |

| Battery Life | 3–12 Months (Highly variable) | 5–7 Years (Designed for low power) |

| Best For | Small residential tanks close to the house. | Large residential, commercial, and remote critical-use tanks. |

Step-by-Step Installation and Setup

One of the best features of modern RTM systems is the ease of installation. If you can change a lightbulb, you can install one of these monitors, provided you have the right gauge.

1. Pre-Installation Checklist (Don't Skip This!)

Before you even order, confirm these two things:

- Is your tank gauge R3D/Remote-Ready? If you're unsure, snap a picture of the dial under the dome and send it to the monitor supplier. This step prevents 90% of user frustration.

- Do you have an adequate cellular/Wi-Fi signal at the tank? For cellular, check the coverage map for the specific carrier the monitor uses. For Wi-Fi, take your phone out to the tank—if the signal is weak, you'll need a range extender or you should opt for a cellular unit.

2. The Simple 5-Step Physical Installation

Safety is always the priority, but because RTM sensors are non-invasive (they don't deal with the actual gas lines), the process is straightforward:

- Locate and Prep: Find your tank dome/lid. No need to turn off the gas, but ensure the area is clear of debris.

- Expose the Gauge: Lift the lid and remove the clear plastic or metal cover from the gauge dial (if present).

- Mount the Sensor: Align the sensor with the R3D dial. The sensor often clips, twists, or magnetically seats directly onto the ready port. A solid connection will feel snug.

- Secure the Unit: Affix the sensor housing to the tank using the supplied magnets, zip ties, or screws. Ensure the antenna (if external) is pointing up and away from the tank body.

- Activate & Test: Follow the manufacturer's instruction to turn the unit on (usually a button press or a magnetic swipe). The unit will communicate its first reading to the cloud.

3. App Setup and Calibration

Once the unit is talking to the cloud, the final step is calibration in the app. This is crucial for accuracy. You must input your tank's exact size (e.g., 500-gallon, 1000-gallon). The app uses this information to correctly convert the percentage reading (e.g., 40%) into a concrete gallon count (e.g., 200 gallons), making your usage and budgeting accurate.

Troubleshooting and Common Pitfalls

Remote monitoring is reliable, but it’s not immune to real-world factors. Being prepared for common "gotchas" is the difference between smooth operation and frustration.

1. The Dreaded "No Reading" or "Offline" Status

If your unit goes dark, the issue is almost always connectivity or power.

- Signal Loss: For a Wi-Fi unit, confirm the 2.4 GHz band is strong and that your router hasn't been moved. For a cellular unit, check the provider's coverage map. Sometimes, simply moving the sensor housing a few inches (especially if it’s on a buried tank dome) can improve the signal.

- Battery Death: If the unit is old or has struggled with a weak signal, the battery may be dead. Tip: Don’t try to use standard alkaline batteries; they cannot handle the cold or the power burst needed for transmission. Always use high-quality Lithium batteries as recommended by the manufacturer.

2. Inaccurate Readings and the Temperature Effect

Your app shows 50% in the morning, but 48% by noon, and maybe 52% that evening. Is the monitor broken?

- No, this is normal. Propane is a liquid under pressure. Its density changes with temperature. While the actual mass of propane remains the same, the volume (and thus the reading on the gauge) fluctuates based on how hot or cold the tank is. A high-quality app will often report a Temperature Corrected Level to give you the most accurate usage estimate.

3. Tank Ownership and Supplier Conflicts

This is the big one that suppliers often don't detail: Can you use a third-party monitor on a dealer-owned tank?

- The Answer (Trustworthiness): Often No. Most propane suppliers who rent or lease tanks to customers include a clause in their contract stating they retain the right to install their own telemetry. Installing a third-party monitor may violate your contract, particularly if they are using their own monitoring system (like Superior's SMART Tank) for automated deliveries. If you rent your tank, call your supplier first. If you own your tank, you have full freedom. Key Entity: Propane Supplier/Dealer.

Conclusion

Remote propane monitoring is no longer a niche gadget; it is a foundational pillar of modern energy management. For the homeowner, it’s the ultimate defense against the high cost of emergency delivery and the catastrophic damage of a winter run-out. For the business or farm, it’s a necessary tool for code compliance, supply chain efficiency, and predictive asset management.

The key to success lies in making the correct choice between cost and reliability: Choose Cellular for maximum reliability, long battery life, and remote use. Choose Wi-Fi only if your tank is extremely close to a powerful router. Above all, always ensure your tank is equipped with the necessary R3D gauge to ensure a seamless setup.

Key Takeaways:

- Eliminate Guesswork: Emergency delivery costs are far higher than the lifetime cost of a monitor.

- Reliability is King: Cellular monitors (LPWAN) are the professional standard with 5+ year battery life.

- Verify Your Gauge: Your tank must have an R3D-ready gauge for easy, non-invasive installation.

Ready to stop guessing and start monitoring? Check out our complete list of the best cellular and Wi-Fi monitors on the market to find the perfect solution for your needs. The Smart Propane LP Gas Tank Monitoring Guide

Expert FAQ Section

Propane monitor costs vary primarily by connectivity. You can expect to pay $100–$200 upfront for a basic Wi-Fi unit with no monthly fee. Cellular units, which offer vastly superior reliability and battery life, cost more, typically ranging from $250–$350 upfront, plus a recurring subscription fee of $5–$8 per month to cover the cellular data transmission. This subscription cost is often offset by avoiding a single emergency delivery charge.

Cellular (LPWAN) monitors are specifically engineered for ultra-low power consumption. They typically send data only a few times per day, minimizing energy use. As a result, they use high-capacity lithium batteries that are designed to last for an industry-leading period of 5 to 7 years or longer. Wi-Fi units, conversely, will likely require battery replacement annually or even semi-annually due to the higher power draw required to maintain the Wi-Fi connection.

Yes, smart monitors can be used on underground propane tanks, provided the access dome is large enough to install the sensor onto the R3D gauge dial. The key is ensuring that the cellular or Wi-Fi signal can transmit reliably from the underground housing. Cellular networks are generally more effective in this scenario due to their stronger, dedicated signal architecture compared to a residential Wi-Fi network's limited range.

While magnetostrictive and pressure sensors offer high precision for large industrial applications, the most common and practical system for residential and small commercial use is the R3D-ready float gauge with a magnetic sensor. This is because the float gauge is a direct mechanical reading of the liquid level inside the tank, offering the best balance of accuracy, cost, and non-invasive, do-it-yourself installation.

The data is primarily generated and transmitted through the sensor manufacturer's cloud platform. If you purchased and installed your own monitor, you own the data and control who sees it. If your propane supplier installed the monitor, they use the data for their automatic delivery forecasting; in this scenario, while you can view your data via their customer portal, the supplier controls the primary stream used for logistics.

NFPA 58 is the Liquefied Petroleum Gas Code, and NFPA 99 is the Health Care Facilities Code. Both contain strict requirements for maintaining backup fuel reserves, especially for critical infrastructure like hospitals or data centers that use propane-powered generators. Remote monitoring is the simplest, most auditable way to meet this requirement, as it provides a constant, digital log that proves fuel levels have been maintained above the mandated safety thresholds.